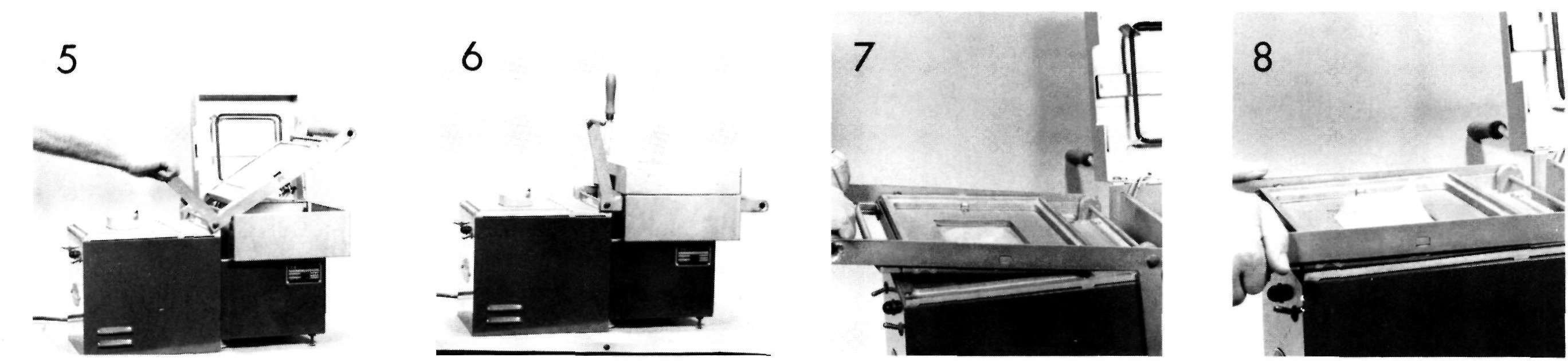

Figure 6 The material is heated for a specified period of time.

Figure 7 After the material is softened the heating unit is opened and the material in its holder is rotated toward the cast on the front of the machine. The vacuum pump is started just prior to this step so that a vacuum will be formed between the cast and the softened material as they come together.

Figure 8 The rack holding the soft material is pressed firmly to place to insure that a vacuum is developed between the cast and the softened material.

Figure 9 The vacuum pulls the material into close apposition with the cast. The material is allowed to cool before it is removed from the machine to minimize distortion.

Figure 10 A coarse stone is used to cut the material around the edge of the cast. The excess is removed, and then the tray is removed from the cast.

Figure 11 The outline is marked on the tray.

Figure 12 The tray is trimmed to the outline. Refining the edge with an arbor band as shown in Section 13, Figure 8 will produce a smooth border.

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses