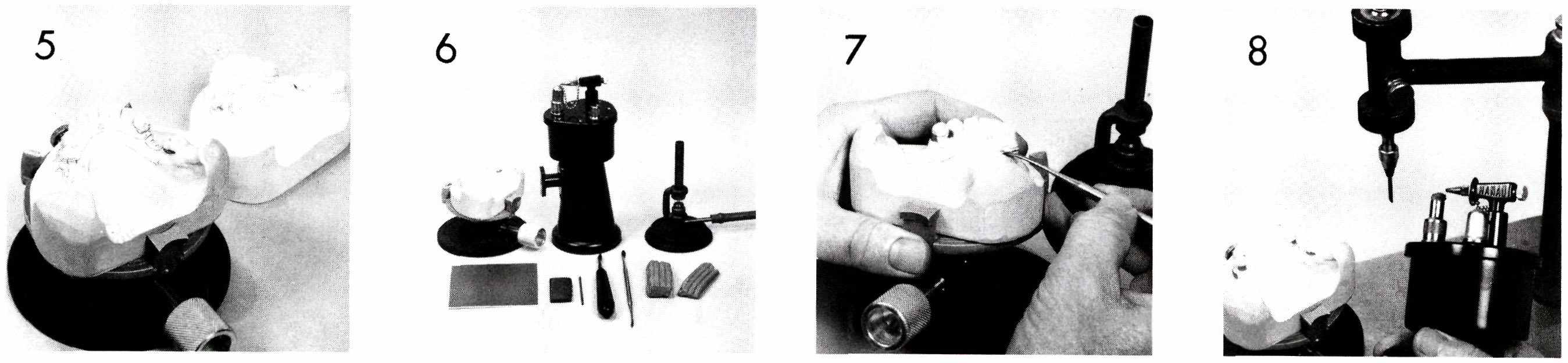

Figure 7 A small amount of baseplate wax is placed in the undesirable undercuts. This includes undercuts on the teeth and soft tissue undercuts which must be eliminated.

Figure 8 The beveled bur shank is placed in the surveyor and heated with a Hanau torch.

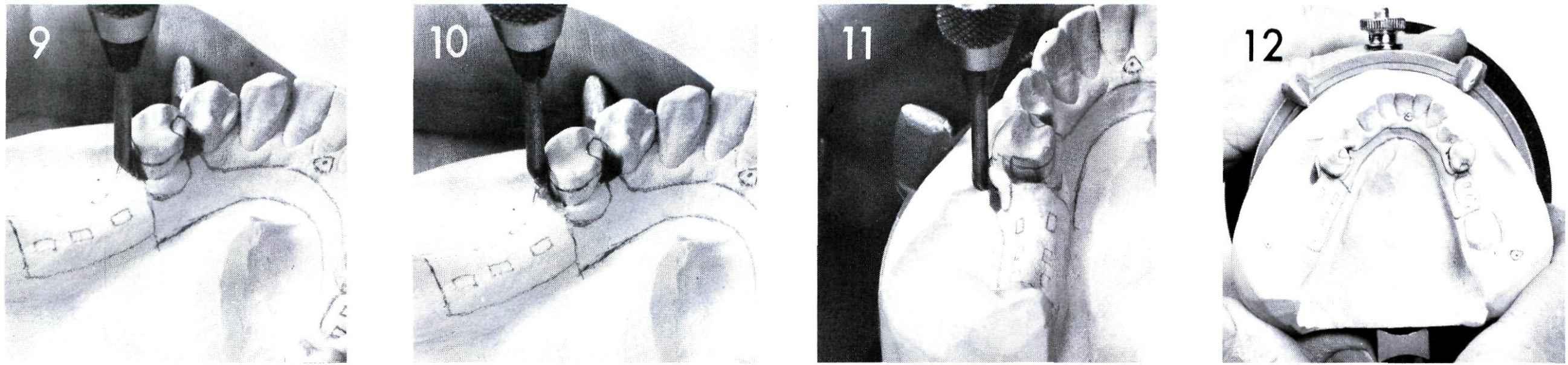

Figure 9 The excess wax in the undercuts is removed by moving the teeth against the warm bur shank. The surveyor table will move easily if a few grains of acrylic polymer are sprinkled on the base of the surveyor.

Figure 10 A wiping motion is used to smooth the wax.

Figure 11 A tissue undercut which may be crossed by a minor connector is treated in the same manner as tooth undercuts.

Figure 12 All undesirable undercuts have been eliminated.

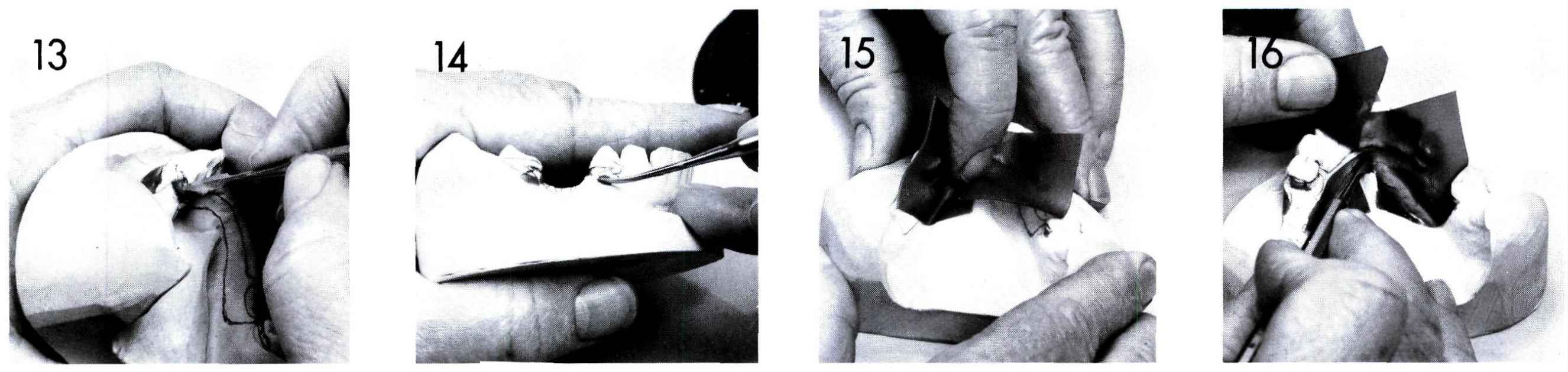

Figure 13 Any wax which has flowed above the survey line is removed. Care must be taken not to scratch the surface of the cast.

Figure 14 A small amount of wax is added to the surface of the tooth where the tip of the clasp will lie. A sharp ledge is cut into this wax. This will produce a mark on the refractory cast which will indicate the position of the tip of the clasp.

Figure 15 The inferior two-thirds of the lingual bar must be relieved on mandibular free-end extension partial dentures. (It generally is good practice to relieve all lingual bars this way, be they for free-end extensions or tooth borne partial dentures.) This is done by adapting 30 gauge wax in the area of the lingual bar. It must be thoroughly adapted to the cast with no air trapped beneath it.

There may be situations where additional relief is needed. An example is a lingual torus, a bony protruberance lingual to the canines and premolars, which requires substantial relief to avoid irritation in the future.

Figure 16 The wax which extends above the inferior two-thirds of the bar is removed. The design on the master cast may be seen through the wax and acts as a guide for removal of the excess gauge wax.

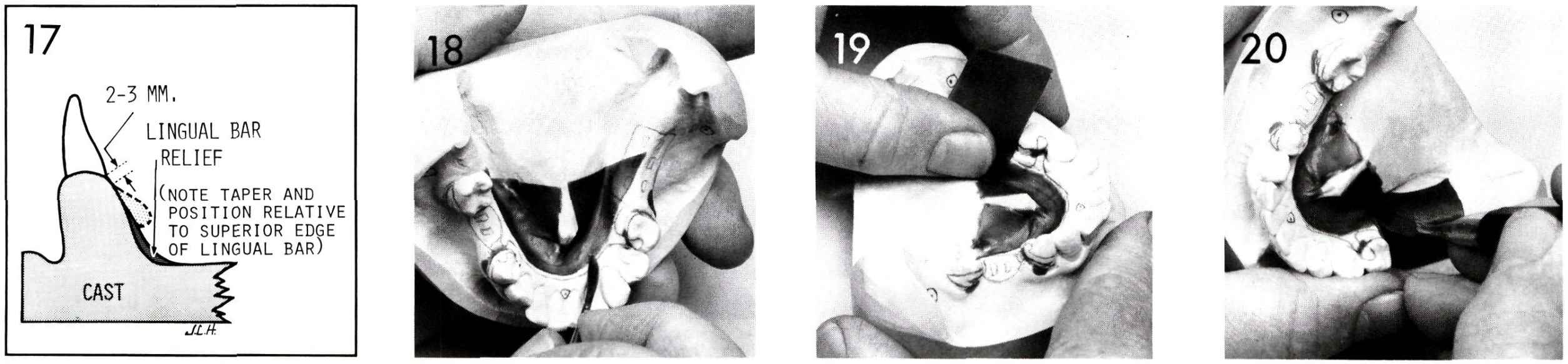

Figure 17 The superior surface of the lingual bar relief must be feathered into the cast. This prevents a ledge from being formed on the tissue side of the lingual bar.

Figure 18 The superior edge of the lingual bar relief is feathered using a warm, not hot, spatula.

Figure 19 The relief for the area where the free-end extension will lie is made by using a double thickness of 28 or 30 gauge wax. This double thickness of wax is adapted to the edentulous ridge adjacent to the distal abutment tooth. (Note how the anterior edge of this wax overlaps the lingual bar relief.) This relief wax eventually will result in a space between the metal framework and the cast and permits the attachment of the denture base resin to the framework.

Figure 20 The relief for the plastic retention over the edentulous ridge is trimmed so the anterior edge forms a definite ledge immediately inferior to the distal abutment tooth. This ledge will form the internal finish line on the completed partial denture and should slant slightly posterior from the distogingival margin of the abutment tooth. It should never lean forward; otherwise, the plastic denture base material will lie directly below the abutment tooth.

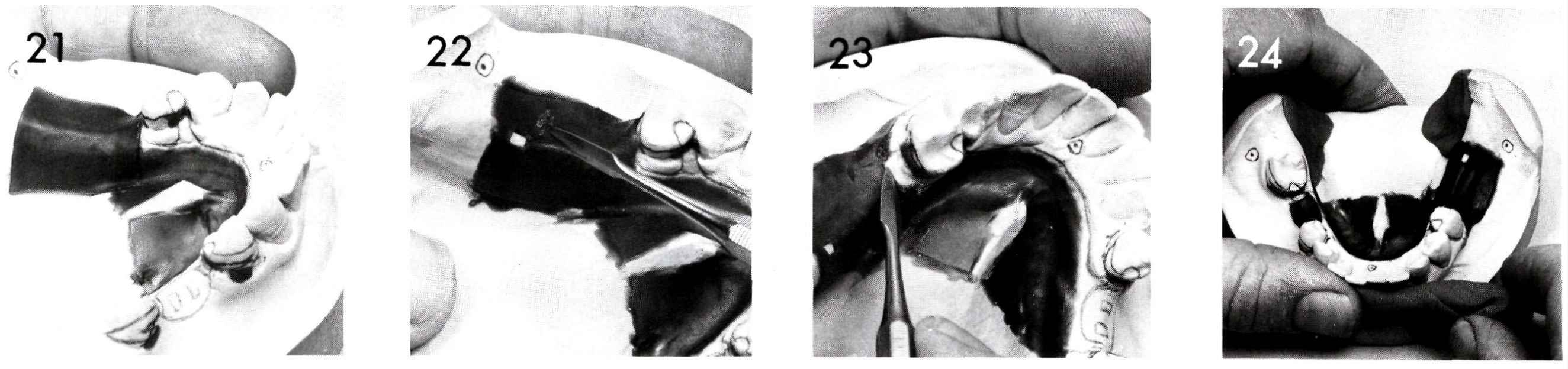

Figure 21 This illustrates the proper placement of the internal finish line. Note that it is a sharp line or step formed by the relief over the edentulous ridge and the lingual bar relief.

Figure 22 A small square of wax cut out of the relief over the edentulous ridge will prevent the framework being displaced during the packing procedures. (This step is not necessary but will give some degree of assurance that the framework will not be displaced during packing.)

Figure 23 A small area of wax is removed immediately adjacent to the abutment tooth. This permits metal to lie on the tissue adjacent to the abutment which many dentists feel is healthier than having denture base resin in this area. An additional advantage is that this metal provides a definite place for finishing and prevents excessive space from being created next to an abutment tooth. Such a space can lead to a growth of inflammatory tissue in this area.

Figure 24 A double thickness of 28 or 30 gauge wax is placed over the edentulous ridge between the abutment teeth on the right side of the cast. This is trimmed to follow the line on the lingual side of the ridge which is shown clearly in Figure 23

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses