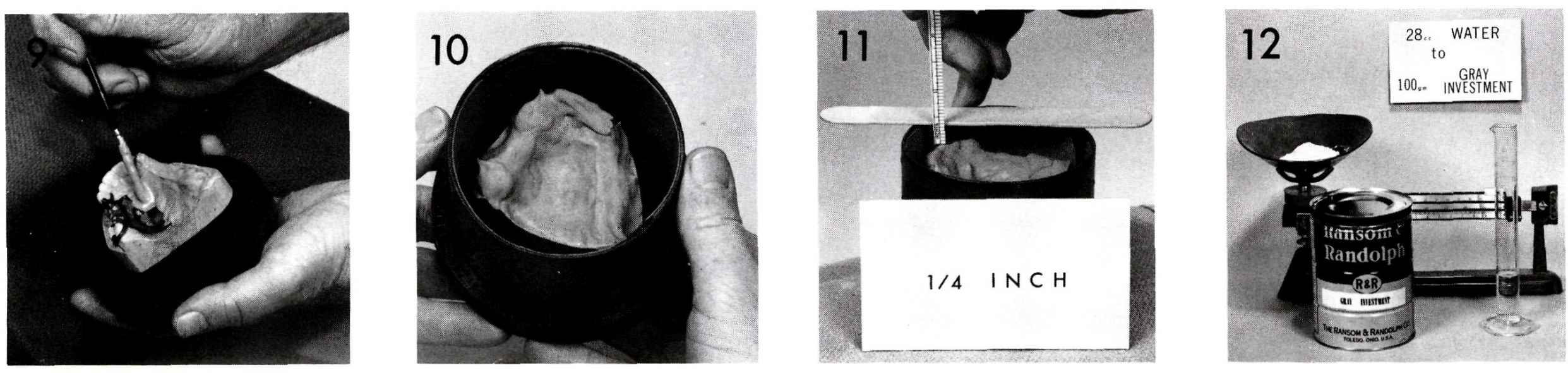

Figure 2 Wax is used to attach the investment cast firmly to the sprue base.

Figure 3 The cast is positioned with the main sprue hole over the center of the sprue base.

Figure 4 The main sprue hole is filled with wax.

Figure 5 The casting ring is lined with a material designed for this purpose. Strips of the material are cut to the proper length, placed in the ring, sealed with a small amount of wax and the ring is dipped in water to wet the material. The material must be wet so that water will not be drawn from the investment.

The liner permits the investment to expand when it is heated but must be placed so that inch of the casting ring is exposed on the top and the bottom of the ring. This keeps the investment from falling out of the ring when it is removed from the oven.

A cast which has not been dipped in beeswax must be soaked in water for 5 minutes before investing. If beeswax, which seals the surface of the cast, is used, soaking is not necessary.

Figure 6 The wax pattern is coated with a surface tension reducing agent. This allows the investment to flow evenly over the pattern without trapping air bubbles.

Figure 7 The investment used for the outer portion is the same used for the investment cast. Note that the ratio is 28cc. of water to 100 grams of investment. This produces a thinner mix than was used for the investment cast. Thus, the outer investment expands less than the refractory cast, producing a tight joint between the cast and the outer investment. Always be certain that the refractory cast is made from a thick mix of investment and the outer investment is a thin mix.

Figure 8 A small amount of investment (50 grams) is first mixed. A mechanical spatulator produces a smooth, creamy mix which is easily painted on the pattern.

Figure 9 The investment is painted on the pattern with a camel’s hair brush. The hand holding the brush is held against a vibrator and the investment is flowed over the wax pattern ahead of the brush to avoid trapping air bubbles. Do not place the refractory cast on the vibrator. This causes particles of investment to settle toward the cast and gives the same effect as a thick mix of investment, resulting in casting fins. The pattern is completely covered and is then set aside until the investment sets.

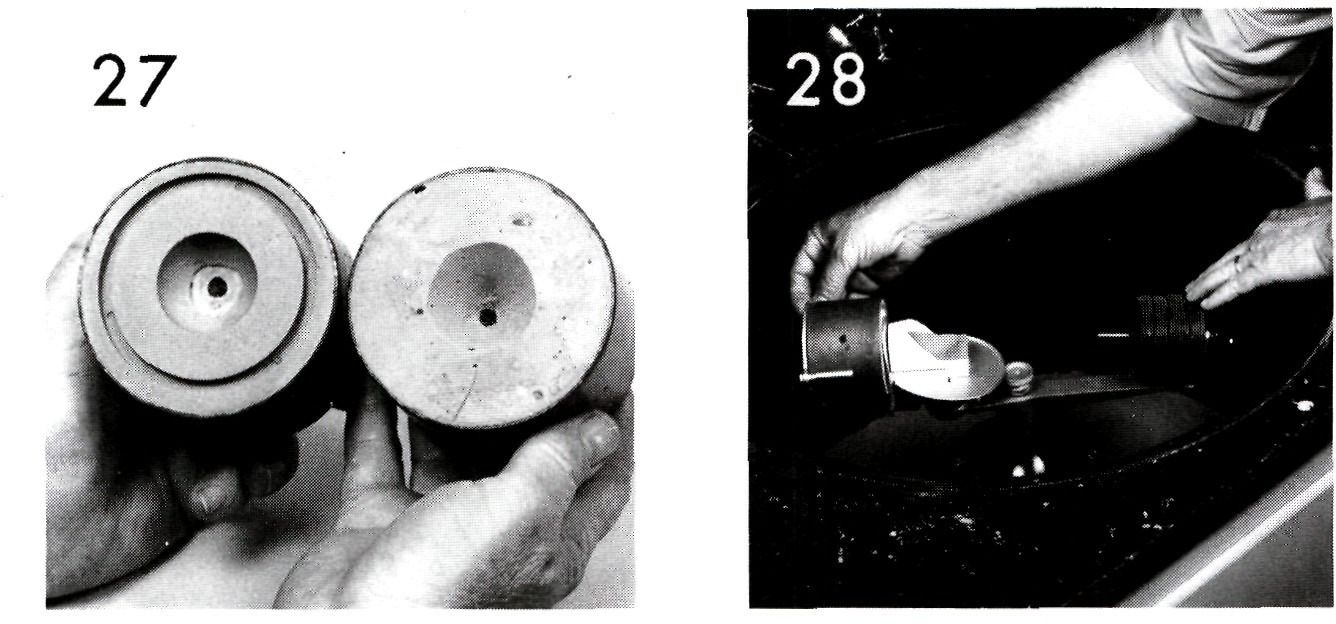

Figure 10 The casting ring with the wet liner is placed over the sprue base and cast to be sure that it fits within the ring.

Figure 11 The pattern should be one-quarter of an inch from the top of the casting ring. This thickness gives sufficient strength to the investment and allows gases trapped by the molten metal to escape through the investment during the casting procedure.

Figure 12 A 28 to 100 mix of investment is made using 400 grams of investment.

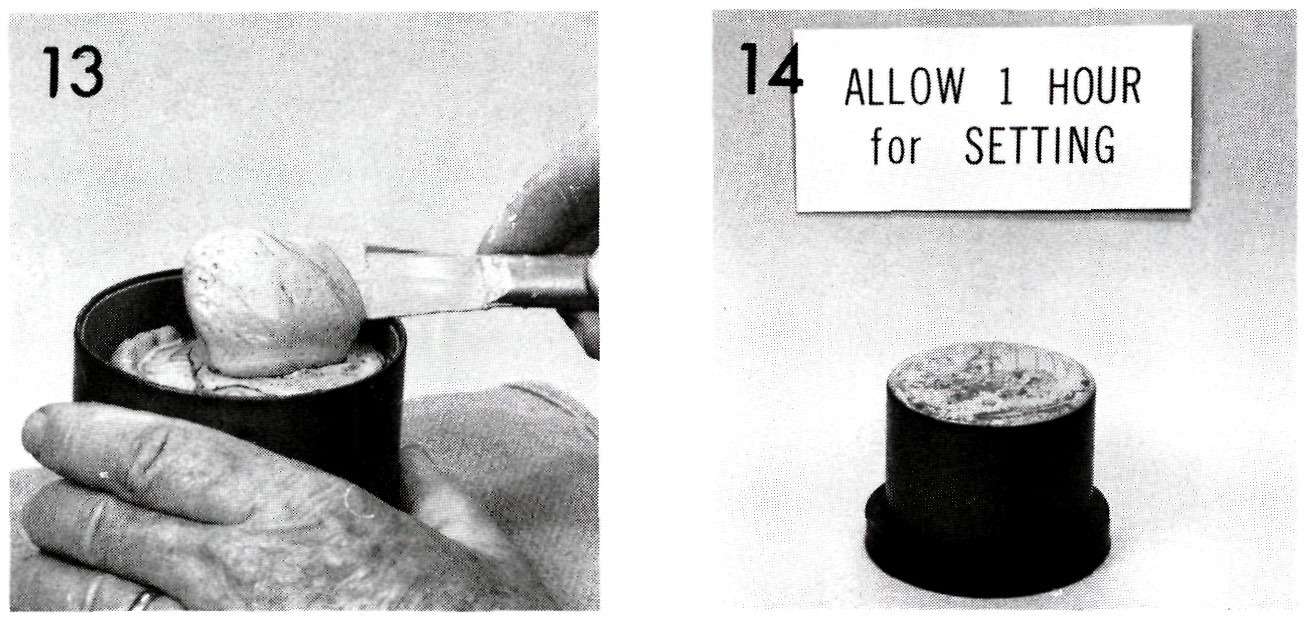

Figure 13 The ring, with the sprue base attached, is placed on a vibrator and is filled with investment.

Figure 14 The investment is allowed to set for one hour.

Figure 15 The auxiliary sprues for the mandibular partial denture are made of 8 gauge round wax. They are attached to the thickest portion of the framework and the junction is rounded to eliminate sharp edges in the mold. This casting, being relatively small, requires only two auxiliary sprues which are curved to provide a smooth pathway for the gold entering the mold.

Figure 16 A stick of inlay wax acts as the main sprue. This is placed through the base of the cast.

Figure 17 The main sprue is attached to the auxiliary sprues. The junction is smooth and rounded.

Figure 18 The main sprue is sealed to the base of the investment cast.

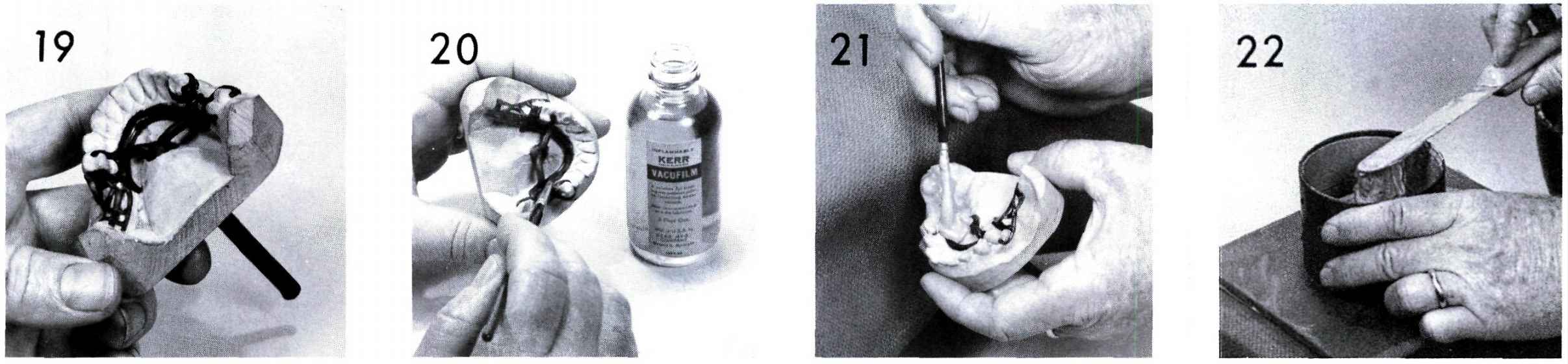

Figure 19 The mandibular pattern is ready to be invested (first, see Figure 24).

Figure 20 The wax pattern is painted with a surface tension reducing agent.

Figure 21 A single investment technique uses one large mix of investment. The investment is mixed in a 28 to 100 ratio and is painted on the pattern in the same manner as was done for the maxillary pattern.

Figure 22 The casting ring, lined with a wet lining material, is placed on a glass slab covered with a wet paper towel. The balance of the mix is vibrated into the casting ring.

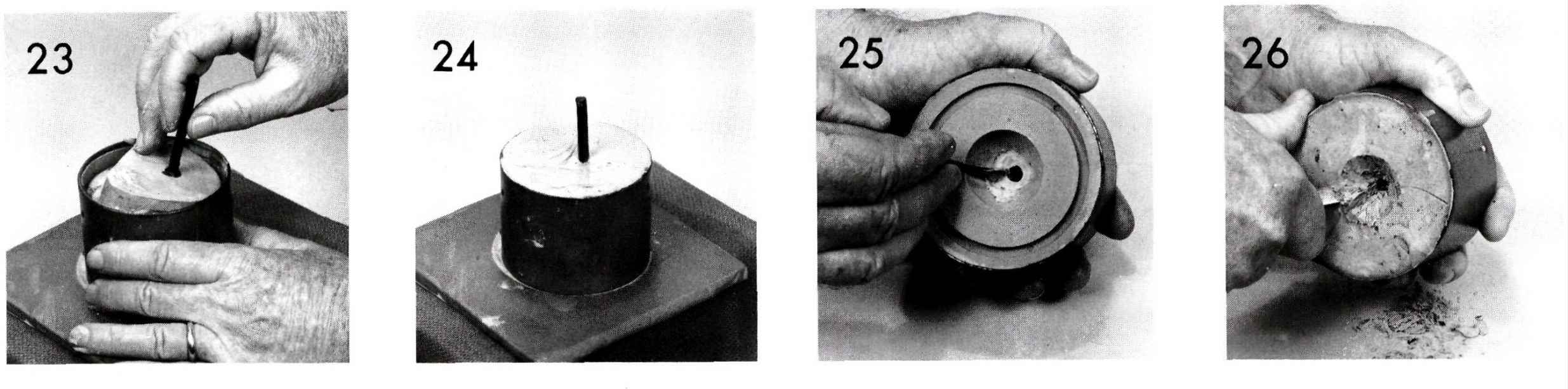

Figure 23 The casting ring and glass slab are held on a vibrator and the mandibular cast, previously painted with investment (Figure 21), is rotated into the investment. The rotation prevents trapping air in the tongue space.

Figure 24 The cast is vibrated into position until the surface of the pattern is ¼ inch from the base of the ring. This is determined before investing by marking the main sprue even with the top of the ring when the wax pattern is ¼ inch from the base of the ring. The investment is allowed to set for one hour.

Figure 25

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses