Introduction

The objective of this study was to quantify the properties of commercially available nickel-titanium open-coil springs.

Methods

Eleven springs from 3 manufacturers were tested 5 times over a 12-week period. A universal testing machine was used to measure the force generated when open-coil springs were compressed to half of their original length and then gradually allowed to decompress.

Results

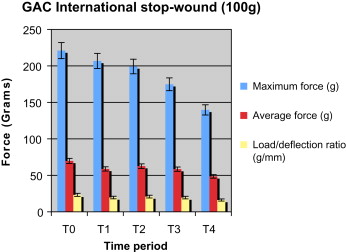

The average forces generated at the initial recording session for uniformly wound springs from GAC International (Bohemia, NY) and 3M Unitek (Monrovia, Calif) were 19.3% to 42.7% and 9.7% to 38.8% below the manufacturers’ labeled force levels, respectively. GAC’s 100, 150, and 200 g stop-wound coils demonstrated statistically and clinically significant stepwise force degradation over the 12-week experimental period ( P <0.0001). GAC’s uniformly wound light (100 g) coils generated the lowest load-deflection ratios (23.7 g/mm).

Conclusions

Open coils might need to be compressed by more than one-third of their original length to produce the labeled forces. Uniformly wound coils generally produce lower load-deflection ratios and maximum forces, which are generally more acceptable for tooth movement.

Editor’s comment

Coil springs have been a useful intraoral tool for space closure and opening for decades. The application supposedly became more reliable with the introduction of the nickel-titanium (NiTi) alloys, which offer steady force-deflection ratios, independent of compression. The objective of this study was to quantify the properties of commercially available NiTi open-coil springs used in everyday orthodontics through a simplified in-vitro test, which nonetheless provided useful information. The authors selected 11 different springs from 3 manufacturers and tested them 5 times over a 12-week period; they used a testing machine with the coils compressed to half of their original length. The average forces generated at the initial recording session for uniformly wound springs varied but were as high as 39% below the manufacturers’ labeled force level. The results generally suggested that the forces developed deviated from the manufacturers’ specifications, and clinicians might want to consider modifying the compression percentages of coil springs. Also, uniformly wound coils generally produced lower load-deflection ratios and maximum forces, which are usually considered more acceptable for tooth movement. Although these results derive from an in-vitro study, and thus the extrapolation of absolute values to clinical conditions might not be accurate, this article highlights the variability between reported and actual values, and emphasizes the necessity for strict quality-control measures and screening the properties of orthodontic materials.

Theodore Eliades

Athens, Greece