22 Fracture of Endodontic Instruments: Torque and Fatigue

One of the complications of endodontic treatment most dreaded by clinicians is the fracture of an instrument within the root canal. Even though instrument fractures per se are not regarded as a professional error, the patient must be informed. Inadequate disinfection of the root canal system before instrument fracture can affect the prognosis of the treatment (Spili et al., 2005).

Endodontic hand instruments fabricated from stainless steel are less susceptible to fracture, and when this occurs it is usually due to improper technical use. The rotary movement of Hedström (H) files and the use of excessive force with small diameter files are usually the primary culprits.

Stainless-steel instruments undergo a clearly discernible plastic deformation before fracture. With rotary NiTi instruments, plastic deformation occurs less often; in certain situations these instruments can fracture without any warning. Overall, fracture of rotary NiTi instruments is somewhat more common than of K files made of stainless steel (5.1% vs. 3.3%, respectively; Spili et al., 2005). Thus for effective clinical use of rotary instruments, a thorough understanding of fracture mechanisms is very important.

22.1 Cyclic fatigue

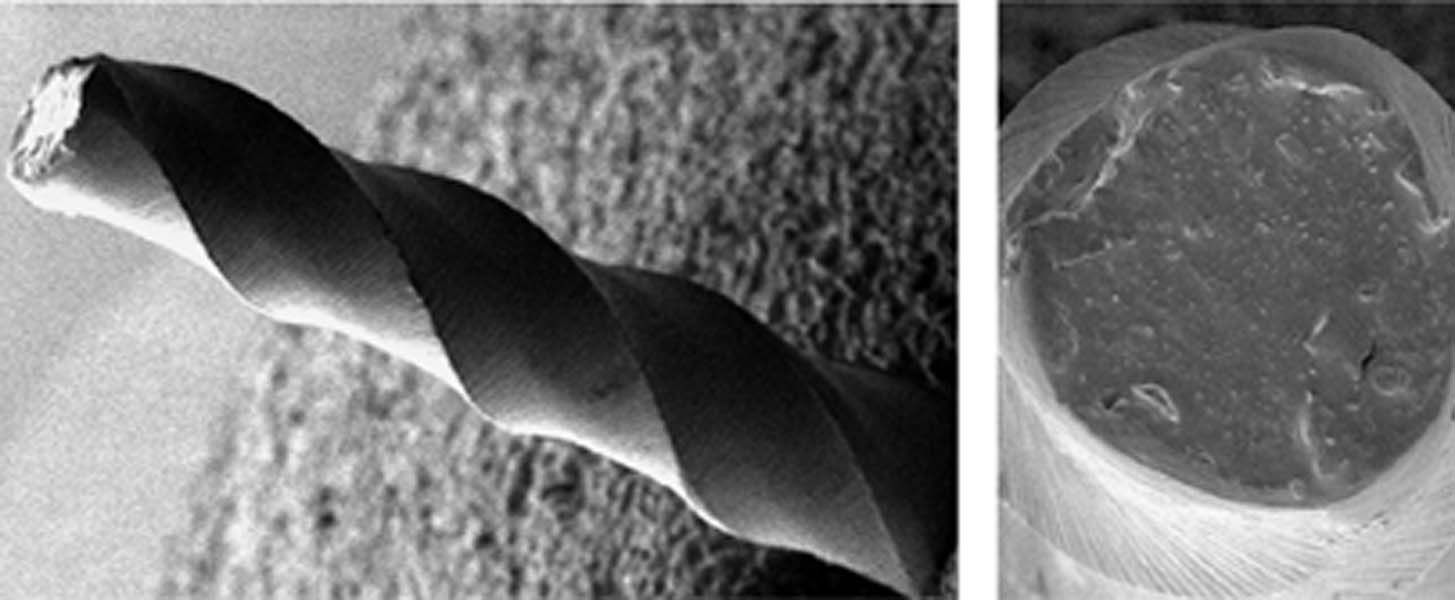

Scanning electron photomicrograph showing a fragment of a Flex-Master instrument (VDW) of size 25 and taper 0.6. The cutting edges do not exhibit any plastic deformation.

Right: This cross-sectional view reveals a somewhat “lumpy” but nevertheless homogeneous surface.

22.2 Torsion loading

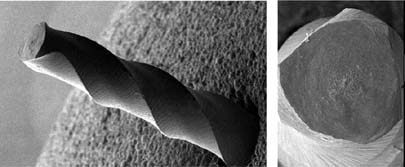

Scanning electron photomicrograph of a fragment of a Flex-Master instrument of size 25 and taper 0.6. Plastic deformation of the cutting edges is clearly visible toward the break surface.

Right: This cross section of the instrument shows a netlike pattern in the middle of the instrument, which is typical after torque loading.

Sattapan et al. (2000) described two different mechanisms for the fracture of NiTi instruments: cyclic fatigue and torsional overloading. Cyclic fatigue of instruments is the result of local work hardening (which makes the file brittle) and eventually leads to fracture. As there is no plastic deformation before this occurs, there are no warning signs of cyclic fatigue.

In contrast, with torsional loading one may note deformation of stainless-steel instruments and occasionally also of instruments made of NiTi alloy. For this reason, all rotary instruments should be visually inspected before reuse after sterilization.

Recent analyses and evaluations demonstrate that both factors are present together clinically and influence each other reciprocally: Fatigue reduces torsional resistance, and vice versa (Fife et al., 2003, Ullmann and Peters, 2005). Additional factors include possible corrosion and the quality of the instrument material, as score marks left on the surface of the instrument during the manufacturing process can be the starting point for cracks and subsequent fracture.

Crystal Structure of Nickel-Titanium and Steel

In contrast to stainless steel, NiTi alloys exist as two different crystal structures (Thompson, 2000): austenite and martensite. At room temperature NiTi assumes its austenitic configuration; with the application of force/tension or with temperature change, the alloy can change its conformation into the stable martensite form. This process permits a reversible deformation of about 7%. To prevent instrument fracture, the degree of deformation must remain below this percentage, because further deformation will weaken the instrument irreversibly, but without any clinically obvious signs.

Instruments within a root canal are loaded rotationally, not linearly. Of importance in this regard is the process of “relaxati/>

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses