Building Technique for the Posterior Region

Clinical application of porcelain-fused-to-metal crowns in the posterior region is quite problematic. The prosthesis may cause changes in the occlusal relationship and elevation due to intraoral cementing, even if it has been fabricated accurately on casts. In such cases, occlusal equilibration is usually necessary at insertion. In addition, patients are subjected to recall examination for checking occlusion and at every recall visit the occlusal surface is adjusted.

If the occlusal surface is made of metal, it can be polished to a smooth finish after equilibration. The relative softness allows for easy attrition and harmonization with mandibular movements.

In contrast, an occlusal surface made of porcelain is very difficult to polish to a smooth finish and becomes rough easily, possibly damaging opposing teeth. Furthermore, the strength and hardness of porcelain material overburdens the antagonists and abutments. In fact, if occlusal contact is not perfectly established without premature contacts in centric relation or during excursion, strong porcelain-fused-to-metal crowns will cause mobility in the abutments or antagonists and eventually may lead to inflammation of the periodontal tissues. For this reason, restoration of the occlusal surface with a porcelain material should be accomplished more accurately than in metal crowns.

However, a well-harmonized occlusion is quite difficult to obtain with porcelain material which has low reproducibility because of high firing shrinkage and surface slumping during glazing particularly with multiple units. Studies currently being conducted relative to accurate occlusion with porcelain materials will require sophisticated techniques and many years of follow-up. Unless a porcelain material without firing shrinkage can be developed, general ceramists cannot solve this problem. Furthermore, the carving of an occlusal surface in porcelain-fused-to-metal crowns is difficult because of the hardness of porcelain material.

In spite of these problems, the restoration of occlusal surfaces with porcelain materials is often demanded in clinical situations because of the demand for improved esthetics.

At present, a full-cast crown with a precisely constructed occlusion is much easier to fabricate than a porcelain-fused-to-metal restoration. The latter should be applied in the posterior region only for the purpose of responding to a demand based on esthetics. This is also true for restoration of an occlusal surface with porcelain material.

These applications must never result in occlusal conditions which will cause destructive effects on the dentition and/or periodontal tissues.

Avoid an occlusal surface made only of opaque porcelain material. In any case, a sufficient thickness of porcelain and the techniques should be taken into consideration so that shade with depth as seen in natural teeth will be reproduced in the occlusal surface as well.

1. Construction of Porcelain Layers

The porcelain layers of a crown in the posterior region are basically composed of layers of dentin, enamel, and transparent porcelain in accordance with the basic building technique of the anterior region. However, this applies mainly to the buccal surface of the premolars which are clearly visible. The occlusal surfaces of the mandibular molars and the maxillary posterior teeth may be constructed with only layers of dentin and enamel porcelain. Since the enamel structure in the posterior region generally is thick, the enamel layer should be thicker in the posterior region than in the anterior region.

2. Building and Carving the Occlusal Surface

Techniques for building and preparation (carving) of the occlusal surface include a powder carving technique in which porcelain is carved during the building prior to firing, and a carving technique in which a crown is carved by cutting after it has been contoured and fired.

Thoroughly condensed porcelain is carved with special small instruments prior to the first baking. Firing usually is accomplished only once. With this technique, a very delicate and esthetically pleasing occlusal surface can be produced but accurate occlusal contacts are difficult to create because of firing shrinkage. Therefore, this technique is indicated only for single or two-unit crowns.

In practice, the build-up is performed by making a crown occlude into the antagonist with the incisal guide pin of an articulator elevated to compensate for firing shrinkage. The degree of compensation should be adjusted for different sites; the degree of elevation decreases posteriorly if the incisal guide pin is elevated. The user of a verticulator type articulator does not encounter such a problem.

At present, carving an occlusal surface by cutting the fired porcelain is relatively easy with effective cutting instruments such as an air-turbine with diamond or carbide burs.

A diamond point is not sharper than a natural tooth fissure. Even when the operator uses the inverted edge of a carbide bur as a cutting edge, it is impossible to make sharper fissures. It is absolutely impossible to adequately represent a fossa with several fissures. To solve the problem and make sharper fissures in the occlusal surface, the author has developed the “non-edge technique”.

With the non-edge technique, a carbide bur FG is inserted in the handpiece than rotated while placing the tip onto a diamond-plated abrasive dresser (SHOFU abrasive dresser) to modify the tip of the bur. The tip is used to adapt to a fissure or fossa. It literally means that we make a bur without an edge and this is the origin of the term “non-edge” for the non-edge technique. This bur is used in an air turbine rotated at high speeds, 200,000 r.p.m. Push the bur very gently along the surface. The non-edge technique is useful not only for delicate carving of an occlusal surface in porcelain but also for modifying interproximal contours in anterior bridge work.

With a single firing technique, establishment of an accurate occlusal relationship is very difficult particularly in extensive prostheses. In fabrication of such a prosthesis, formation of an occlusal surface by the carving technique after creation of a near perfect occlusal relationship through two or three additional build-up procedures, is easier and more effective than the creation of one with the powder carving technique.

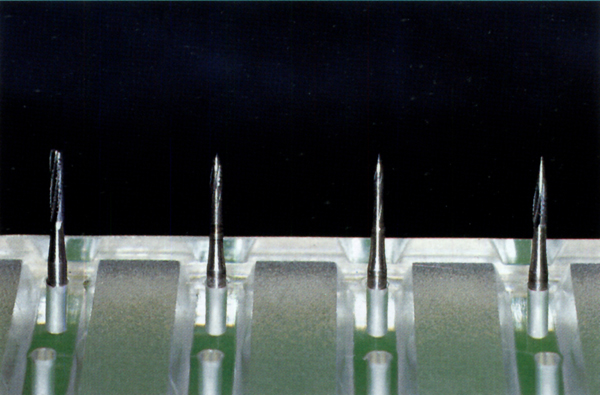

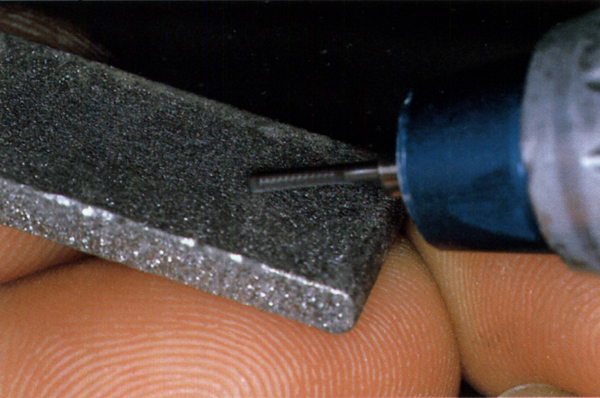

Figs. V-1~V-3 Non-Edge Technique

Fig. V-1 The carbide burs FG used for the non-edge technique. The size or shape of the burs are not important; an old bur is sufficient for this technique. The bur on the far left has not yet been modified. The other three burs have been modified for use in the non-edge technique. It might be useful to prepare several burs with different shapes for this purpose.

Fig. V-2 Preparing carbide bur, FG. The stone* used to modify the burs for the non-edge technique. Insert the bur into the handpiece and rotate the bur and place the tip onto the stone. This action is used to modify the bur tip into the desired shape. (*SHOFU abrasive dresser or a worn diamond disk)

Fig. V-3 Occlusal carving. Use a feather touch to avoid generating heat which can cause the porcelain to crack or fracture. Do not contaminate the porcelain surface with wax or oil since this will affect bur efficiency.

With the carving technique, the build-up of porcelain i/>

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses