Fig. 1.1.

Advanced CNC milling machines are capable of shaping many different BOI designs with defined properties from a single bar of massive titanium

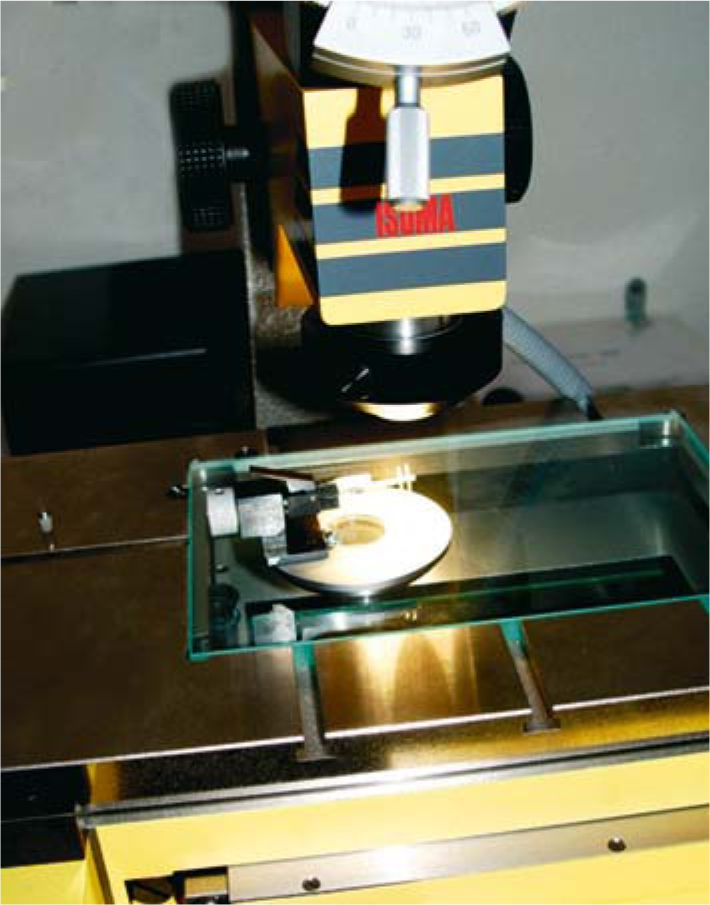

Fig. 1.2.

View of the manufacturing chamber of a CNC milling machine

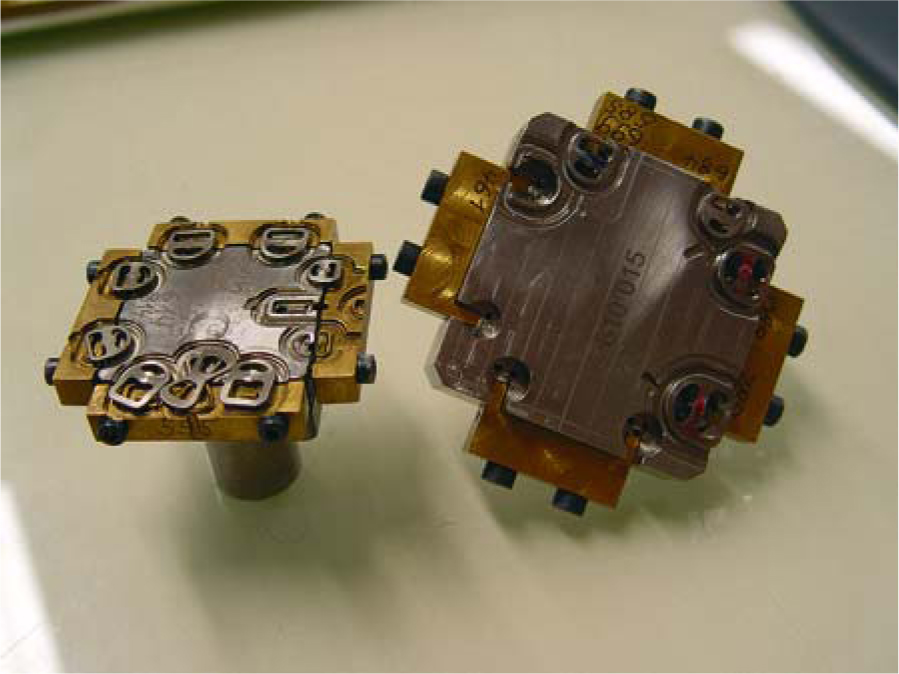

Fig. 1.3.

It is impossible to watch the milling steps due to the extensive cooling requirements

Fig. 1.4.

Some BOI designs need to be adjusted in a second and third step by abrasive instruments. For this purpose, they are mounted on individual tray compartments

-

Low degree of invasiveness (no augmentation, distraction or transplantation)

-

One-step procedure

-

Simple repair in case of problems

-

Combination with natural teeth possible

-

Combination with crestal implants possible

-

Manageable system (few components)

-

Simple laboratory technique

-

Extremely high success rates

Disadvantages of the BOI system include:

-

The stock-keeping requirements are greater than in crestal implantology, i.e. it will always be necessary to keep a few more implants handy to avoid extensive planning including three-dimensional exploration of bone conditions.

-

The technique poses substantial challenges, for instructors and users alike, as far as the surgical and prosthetic treatment stages and the substantial knowledge requirements in the fields of biomechanics and bone physiology are concerned.

Fig. 1.5.

The same triple-disk BOI design in different stages of processing

Fig. 1.6.

Although CNC milling machines are extremely accurate and precise, each specimen is thoroughly inspected

From a business perspective, however, these disadvantages turn out to be advantages after all, since mastering the learning curve will give dentists a comfortable edge over any competitors in the field of implantology.

The question why the outcome of BOI implants is so much better than the results with crestal implants – which specifically includes the survival rates as well – remains to be conclusively answered. Presumably, the prognosis of BOI implants is better from the start, as the blood supply to the bone remains largely intact as a result of the “skeletized” enossal implant fixture. Surface-enhanced crestal implants are susceptible to peri-implantitis, which may lead to progressive ridge resorption. With the BOI technique, this is less of a problem due to the narrow polished emergence of the implants. In addition, the site of bacterial invasion is far away from the site of force transmission. Hence the bone is not burdened with two tasks at the same time. Crater-style collapses are usually avoided this way. Moreover, the implant areas where load transmission takes place are integrated in such a way that the osteogenetic and osteoprotective properties of the cortical bone are optimally utilized.

Fig. 1.7.

An extremely motivated and well-trained team of CNC specialists guarantees reliable quality in the production of BOI implants. During the production phase, any effort must be made is to leave the structure and the strength of the titanium and its elastic properties unaltered

In BOI systems, the fate of the alveolar ridge is not linked to the fate of the implant-restoration complex, since the areas where load transmission takes place are spatially separated from the masticatory surfaces. This fact is obvious from the very design of BOI implants. For successful insertion and load transmission, it is irrelevant whether the vertical portion of the implant is embedded in air or in fluid. It is also irrelevant whether bone tissue is deposited directly on the implant surface in this area. This has many desirable implications:

-

Aesthetic considerations aside, the success of implant therapy does not depend on the presence of alveolar bone.

-

In the presence of dysgnathia, masticatory surfaces can be installed at sites that are spatially independent of the skeletal base.

A good emergence profile of restorations on external BOI systems is achieved by workaround solutions due to the small diameter of the threaded pin. For this reason, BOI implant restorations in the aesthetic zone are somewhat harder to realize than with crestal implants (provided there is enough vertical bone to place them) and require a good measure of anticipation on the dentist’s part for correct positioning of the abutments.

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses