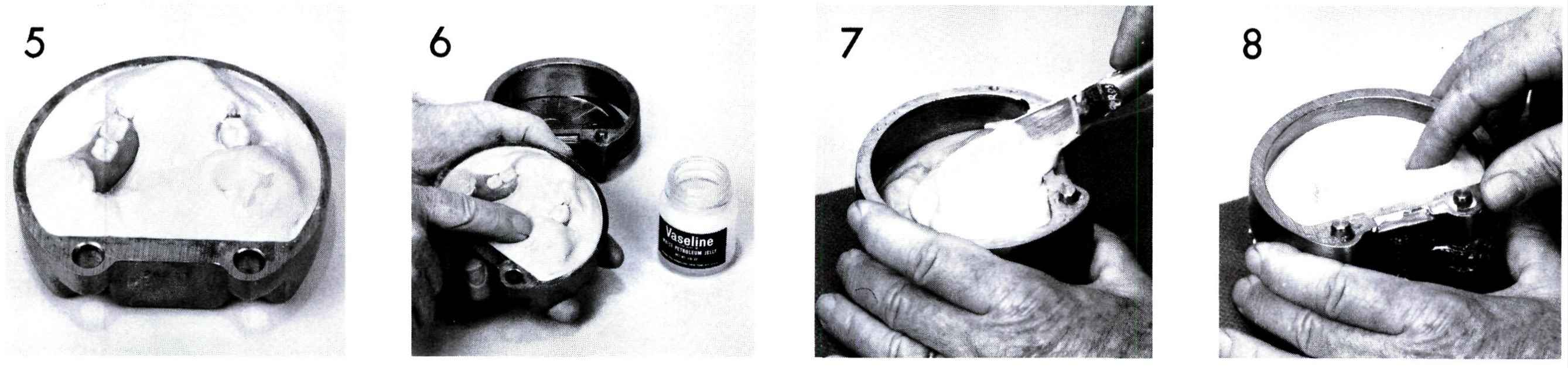

Figure 7 The flask is assembled and the second pour of stone is made.

Figure 8 The occlusal surface of the teeth is uncovered. The second pour is then allowed to set.

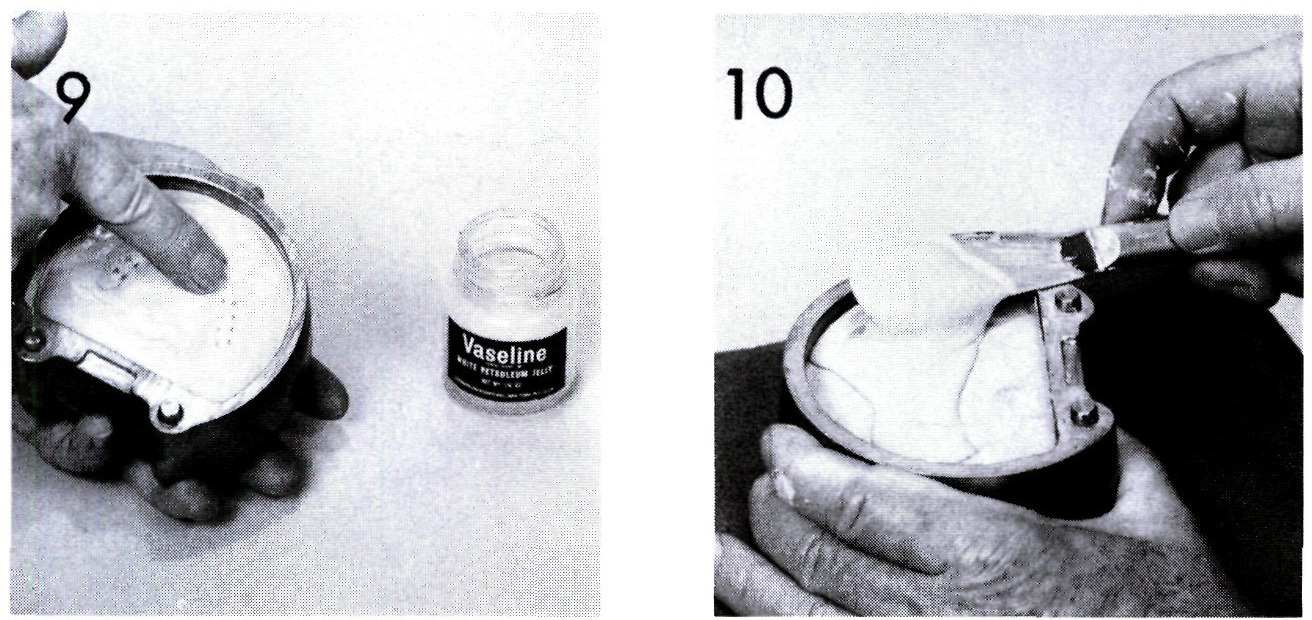

Figure 9 A plaster separator is placed on the entire surface of the second pour. If petrolatum jelly is used, a thin coat should be applied with no excess over the occlusal surface of the teeth.

Figure 10 The third pour, or capping is poured and the lid placed on the flask.

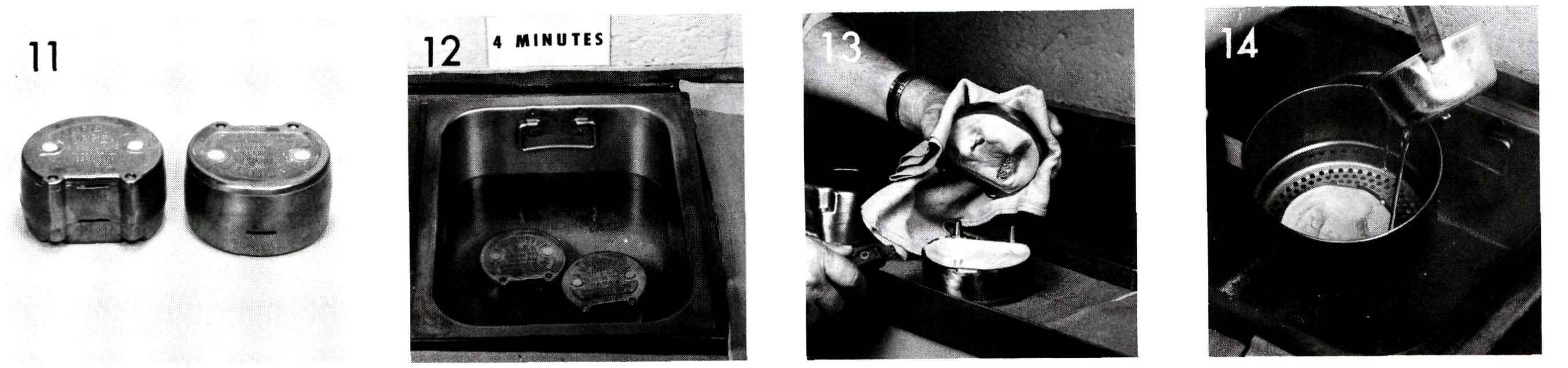

Figure 11 The last pour is allowed to set and the excess removed from the surface of the flask.

Figure 12 The flasks are placed in boiling water for four minutes. The time required for softening the wax will vary depending upon the temperature of the water bath. Four minutes are sufficient in boiling water.

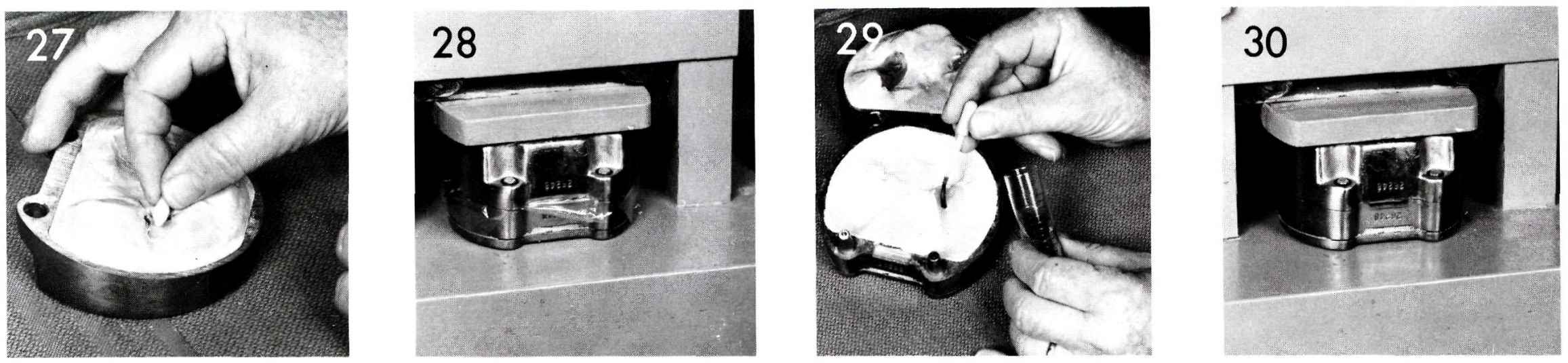

Figure 13 The flasks are removed from the boiling water and are separated.

Figure 14 The wax is flushed from the mold with clean boiling water.

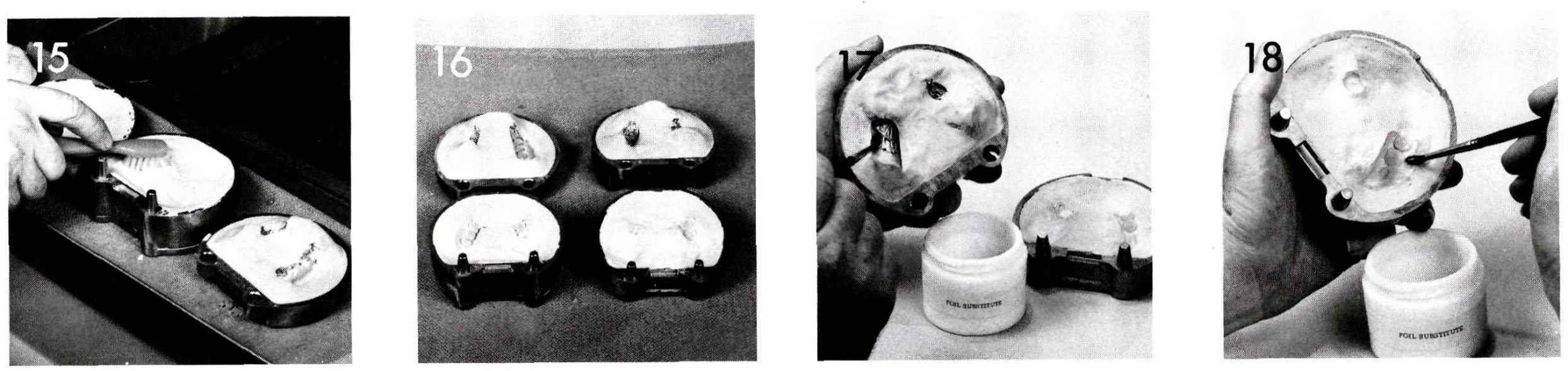

Figure 15 The molds are scrubbed thoroughly with detergent and rinsed in clean, hot water.

Figure 16 The molds are shown immediately after they have been cleaned with detergent and rinsed. They are ready for the application of tinfoil substitute.

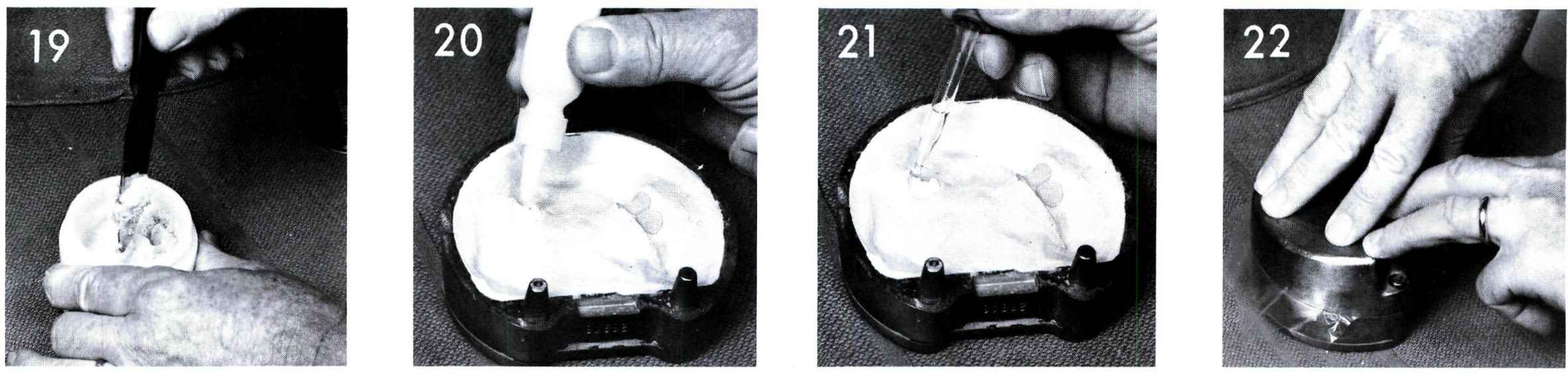

Figure 17 The tinfoil substitute is painted on the tissue surface of the cast. It may be necessary to thin the foil substitute with water in order to have it flow under the frame and completely cover the cast. A second coat of the thin foil substitute may be necessary.

Figure 18 The upper portion of the flask is painted with foil substitute, paying particular attention that the material does not run onto the surface of the teeth. This is particularly important when resin teeth are used as shown here.

Figure 19 The denture base resin is mixed according to the manufacturer’s instructions.

Figures 20 and 21 While the denture base resin is reaching packing consistency, auto-polymerizing tooth colored resin of the prescribed shade is placed into the cavity formed by the wax denture tooth. The mold cavity is first wet with monomer, then polymer is added and more monomer. These steps are repeated until the tooth cavity is filled.

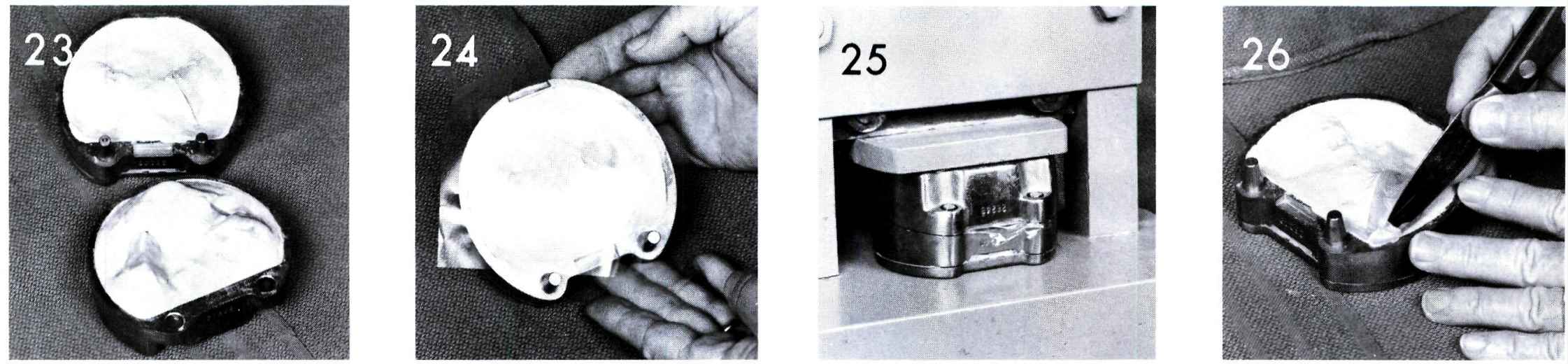

Figure 22 The two halves of the flask are assembled with cellophane interposed and are pressed together. The tooth colored resin is allowed to cure. Closing the flask in this manner assures that the new resin tooth will not interfere with the balance of the packing procedures.

Figure 23 Denture base resin is placed in both halves of the flask. It is pressed firmly around the metal framework. This is necessary so that the metal framework will not tear the denture base resin during the trial packing procedures.

Figure 24 Two sheets of plastic are placed between the two halves of the flask and they are assembled.

Figure 25 The flask is placed in a flask press and approximately 800 pounds of pressure are used. A hand press may be used. Only moderate pressure is needed so do not over-tighten a hand press.

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses