Fig. 7.1

Young’s moduli of α-, (α + β)-, and β-type titanium alloys [6]

The Young’s modulus of β-type Ti alloys is considered to be closely related to the stability of the β-phase. For example, the Young’s modulus of Ti–Nb alloys, which is quenched above the β transus temperature, depends on the niobium (Nb) content [14, 15]. Depending on the chemical composition, Ti alloys exhibit some intermediate phases, such as non-equilibrium hcp-α′, orthorhombic-α″, and hexagonal- or trigonal-ω phases between the equilibrium α and β phases [17]. As a function of the chemical composition, the Young’s modulus of Ti–Nb alloys shows local maximum at the chemical composition in which the ω phase is formed by quenching (Ti–30Nb). Conversely, the Young’s modulus of Ti–Nb alloys shows local minimum at the chemical composition in which the lowest Nb content in the range of the non-ω phase is formed by quenching (Ti–40Nb) [14, 15]. This implies that the formation of the ω phase has to be suppressed in order to obtain low Young’s modulus in β-type Ti alloys [16]. Furthermore, studies on the temperature dependence of the Young’s moduli of Ti–Nb–Al [11] and Ti–Nb–Sn [9, 16] alloys show that their Young’s moduli reduce close to their α″ martensitic transformation temperature. Figure 7.2 [11] shows a typical example of this case in Ti–24Nb–3Al alloys (only the chemical composition of this alloy is expressed using mol% in this chapter). Therefore, in order to obtain the lower Young’s modulus of β-type Ti alloys closer to room temperature or body temperature, the chemical composition of the alloys should be determined to be their α″ martensitic transformation temperatures just below these temperatures [16]. Newly developed β-type Ti alloys such as Ti–Nb–Ta–Zr [7, 8], Ti–Nb–Sn [16, 9, 15], Ti–Nb–Al [11, 17], Ti–Nb–Ta [18], and Ti–Nb–Zr–Sn [10] alloys are considered to satisfy the abovementioned requirements for obtaining low Young’s modulus of the order of 40–60 GPa, which is close to that of the bone (10–30 GPa) [19].

Fig. 7.2

Dependence of Young’s modulus of a β-type titanium alloy with low Young’s modulus (Ti-24Nb-3Al alloy (mol%)) on temperature. ϕ is angles between longitudinal and rolling directions in specimen, and Ms is α″ martensitic transformation temperature [11]

However, the mechanical reliability of these β-type Ti alloys with low Young’s modulus is typically lesser than that of a common (α + β)-type Ti–6Al–4V ELI alloy. Therefore, improvement in the mechanical reliability of β-type Ti alloys with low Young’s modulus is currently under study [20, 21]. The static strength, namely, the tensile strength and 0.2 % proof strength of β-type Ti alloys with maintaining low Young’s modulus can be achieved to the level of those of Ti–6Al–4V ELI alloy by severe cold working such as severe cold rolling, swaging and forging, and severe plastic deformation such as high pressure torsion (HPT) [5, 22, 23]. However, the dynamic strength, namely, the fatigue strength with maintaining low Young’s modulus cannot be improved by severe cold working or severe plastic deformation [24]. Therefore, to improve fatigue strength of β-type Ti alloys, introducing the secondary phases such as α and ω phases, which are formed by aging, in the β-phase matrix is effective, but increases the Young’s modulus. Therefore, controlling the amount of the secondary phase should be considered to maintain the Young’s modulus as low as possible. One of the way to introduce a small amount of the secondary phase is short-time aging at a relatively low temperature. In this case, the ω phase is attractive because it increases remarkably the strength of β-type Ti alloys although increasing the Young’s modulus. For example, as a result of introducing a small amount of the ω phase by the sort-time aging, the fatigue strength of Ti–29Nb–13Ta–4.6Zr alloy, which is one of the β-type Ti alloys with low Young’s modulus for biomedical applications, increases to a level of that of Ti–6Al–4V ELI alloy while maintaining its Young’s modulus around 75 GPa [20]. Furthermore, introducing a small amount of ceramics such as TiB and Y2O3 to the β-phase matrix is also effective to improve the fatigue strength of β-type Ti alloys [21, 25]. Figure 7.3 [21] shows maximum cyclic stress-fatigue life (the number of cycles to failure) curves, namely, S-N curves of Ti–29Nb–13Ta–4.6Zr alloys with different Y2O3 additions obtained from fatigue tests where the amounts of Y2O3 are expresses as Y concentrations. The fatigue strength is highly improved by Y2O3 additions both in low- and high-cycle-fatigue life regions, where the number of cycles to failure is less than 105 cycles and exceeds 105 cycles, respectively. The fatigue limit of the alloy with 0.1mass% Y is the greatest among the alloys with different Y concentrations. Young’s moduli of Ti–29Nb–13Ta–4.6Zr alloys with different Y2O3 additions are shown in Fig. 7.4 [21]. It indicates that Young’s moduli of Ti–29Nb–13Ta–4.6Zr alloys with different Y2O3 additions are almost similar to that of Ti–29Nb–13Ta–4.6Zr alloy without Y2O3 addition, which is around 60 GPa.

Fig. 7.3

S-N curves of cold-rolled Ti-29Nb-13Ta-4.6Zr alloys (mass%) without and with different Y2O3 additions which are shown as contents [21]

Fig. 7.4

Young’s moduli of cold-rolled Ti-29Nb-13Ta-4.6Zr alloys (mass%) without and with different Y2O3 additions as a function of content [21]

7.3 Wear Properties of Low Young’s Modulus Titanium Alloy

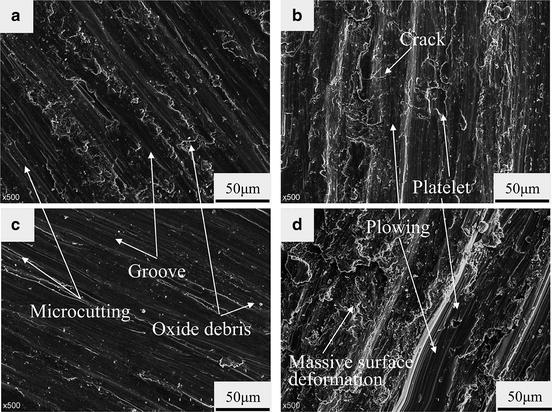

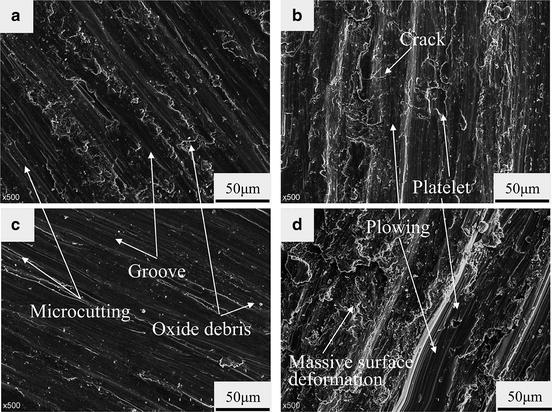

Some orthopedic implants consist of more than one component with metal-to-metal contacts such as spinal fixation devices so that the wear properties of materials is important for use in such the applications. A difference of wear behavior between Ti–6Al–4V ELI alloy and Ti–29Nb–13Ta–4.6Zr alloy was investigated [26, 27]. Volume loss of Ti–29Nb–13Ta–4.6Zr alloy was larger than that of Ti–6Al–4V ELI alloy for both discs and balls (mating materials) in the ball-on-disc type wear testing as shown in Fig. 7.5 [26]. According to wear track observations shown in Fig. 7.6 [27], continuous uniform groove and micro cutting, indicative of abrasion, and oxide debris are observed on the worn surface of Ti–6Al–4V ELI alloy. On the other hand, severe plowing, massive surface deformation, many cracks, and some traces of spalling in the form of platelets, indicative of delamination, are observed on the worn surface of Ti–29Nb–13Ta–4.6Zr alloy. These observation results indicate that the resistance to plastic shearing of Ti–29Nb–13Ta–4.6Zr alloy is lower than that of Ti–6Al–4V ELI alloy, which is intrinsically related to low Young’s modulus, resulting in different wear behaviors between these two alloys.

Fig. 7.5

Volume losses of discs and balls made of Ti–6Al–4V ELI alloy (mass%) (Ti64) and Ti–29Nb–13Ta–4.6Zr alloy (mass%) (TNTZ) obtained from the frictional wear tests [26]

Fig. 7.6

Scanning electron micrographs of worn surfaces of a β-type titanium alloy with low Young’s modulus (Ti-29Nb-13Ta-4.6Zr alloy (mass%) (TNTZ)) and a conventional (α + β)-type titanium alloy (Ti-6Al-4V ELI alloy (mass%) (Ti64)) after ball-on-disc wear tests; (a) Ti64 disc against Ti64 ball, (b) TNTZ disc against Ti64 ball, (c) Ti64 disc against TNTZ ball, and (d) TNTZ disc against TNTZ ball [27]

7.4 Self-Tunable Young’s Modulus

In case of spinal fixation devices, high rigidity can increase the risks of stress shielding effect and adjacent segment degeneration. Therefore, materials with low Young’s modulus are often preferred to realize healthy spine formation [28, 29]. However, these devices also require high Young’s modulus as they are subjected to bending during surgery to obtain the physiological curvature of the spine [30]. In this case, the device must be bent within a limited space inside the patient’s body. Therefore, it is often difficult for the surgeon to make an intended curvature if the spring-back of the spinal fixation devices is relatively large [31]. Furthermore, it has been reported that the bending tool used by a surgeon to bend the device often leads to scratches on the device surface during the surgery. This, in turn, decreases the mechanical reliability of the spinal fixation devices [32]. Large spring-back leads to difficulty in bending, resulting in the repetition of contouring during operation. This increases the risk of failure of spinal fixation devices [33]. The degree of spring-back depends on both the strength and Young’s modulus of spinal fixation devices. Given the same strength, it is the spinal fixation devices with higher Young’s modulus that will exhibit a smaller spring-back. That is, these devices are often preferred to suppress the spring-back [34]. Therefore, there is a conflicting requirement in Young’s modulus from the viewpoint of patients and surgeons, which cannot be completely satisfied by β-type Ti alloys with low Young’s modulus [31]. In order to overcome this issue, recent studies have proposed a novel concept using a deformation-induced ω-phase transformation in β-type Ti alloys [31], such as Ti–Cr [35], Ti–Mo [36], Ti–Zr–Mo [37], Ti–Zr–Mo–Cr [38], and Ti–Cr–O [39] alloys. These materials exhibit novel functionality, wherein the deformed material possesses high Young’s modulus, while the non-deformed part has low Young’s modulus. This is made possible by the phenomenon of deformation-induced ω-phase transformation localized within the deformed part of the material, which provides an opportunity to satisfy the conflicting requirement in terms of Young’s modulus.

Figure 7.7 [31] shows the Young’s moduli of β-type Ti alloys, Ti–12Cr alloy with self-tunable Young’s modulus and Ti–29Nb–13Ta–4.6Zr alloy with low Young’s modulus, after being subjected to solution treatment and cold rolling. The Young’s moduli of both Ti–12Cr and Ti–29Nb–13Ta–4.6Zr alloys subjected to solution treatment are almost similar of the order of 60–70 GPa. After being subjected to cold rolling, Ti–29Nb–13Ta–4.6Zr alloy, in which no phase transformation occurs during cold rolling, reveals Young’s modulus almost similar to that subjected to solution treatment. Conversely, the Young’s modulus of Ti–12Cr alloy is found to increase with cold rolling. The microstructure of Ti–12Cr alloy after cold rolling, as observed using a transmission electron microscope, indicates the formation of the ω phase. In general, the formation of the ω phase significantly increases the Young’s modulus of β-type Ti alloys [24]. Therefore, the observed increase in Young’s modulus of Ti–12Cr alloy as a result of cold rolling could be attributed to the deformation-induced ω phase transformation [31, 35]. The increase in Young’s modulus due to the deformation-induced ω phase transformation was also confirmed experimentally, as shown in Fig. 7.8 [35

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses