5

Mechanical adhesion

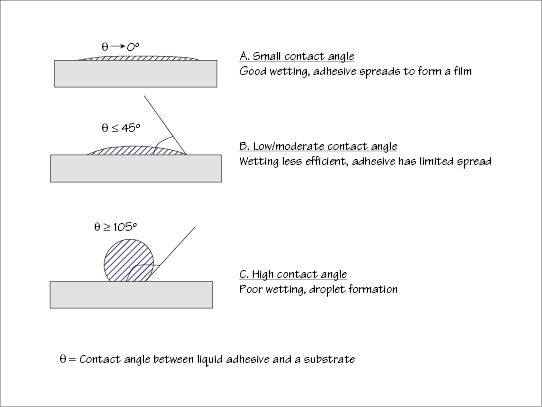

Figure 5.1 Adhesive–substrate contact angles for clean, slightly contaminated, and contaminated surfaces.

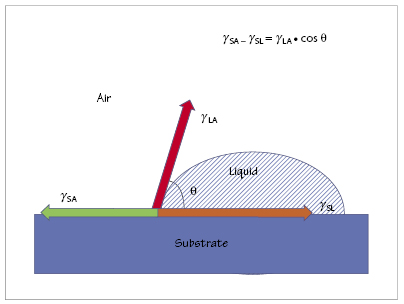

Figure 5.2 Interfacial tensions for a drop of liquid on a surface: θ, contact angle between liquid and substrate; γSA, solid–air interfacial tension (surface energy of substrate); γLA, liquid–air interfacial tension (surface tension of liquid); γSL, solid–liquid interfacial tension (adhesion between liquid and solid).

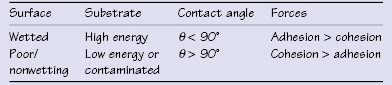

Table 5.1 Relationships among surface wetting, substrate surface energy, contact angles, and adhesive/cohesive forces

Mechanical (actually micromechanical) effects can significantly impact the bond between an adhesive and a substrate, particularly when contributions from chemical, dispersive, and diffusive adhesion are limited or absent. However, for mechanical adhesion to operate, the adhesive must wet the substrate and this is affected by the surface tension of the unset adhesive and the contact angle between it and the substrate.

5.1 Contact angle and surface tension

Adhesives that wet the substrate have larger contact areas than nonwetting materials, with wetting depending on the relative surface energies of adhesive and substrate. Low surface energy materials such as poly(tetrafluoroethylene), or PTFE, and silicone materials do not wet and resist adhesive bonding without special surface preparation.

The ability of a liquid to form an interface with a solid surface, i.e. the degree of wetting, is evaluated as the contact angle θ between the liquid and the substrate surface, θ being determined by both the liquid’s surface tension and the nature and condition of the substrate surface. The degree of wetting increases with smaller contact angles and lower surface tensions (Figure 5.1). Good wetting occurs with clean surfaces, i.e. θ is close to 0° (Figure 5.1A), but the contact angle is greater, i.e. 0 < θ < 90°, with a slightly contaminated surface (Figure 5.1B). With contaminated or low surface energy substrates, θ > 90° (

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses