39

Manipulation and properties of porcelain

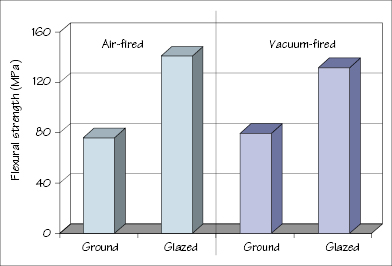

Figure 39.1 Effect of surface condition and firing regimen on porcelain strength.

Box 39.1 Condensation methods for porcelain slurries

Blotting with a brush or 2 × 2 gauze

Mechanically, by vibration or tapping—latter not recommended

Addition of dry powder to surface

Water addition (gravitation method)—not recommended

Table 39.1 Factors in sintering

| Sintering factor | Effect |

|---|---|

| Temperature | Determines glass flow and firing shrinkage. |

| Glass viscosity | Lower viscosity improves flow of glass during sintering. |

| Particle size | Range of particle sizes reduces void space; smaller particle sizes increase interparticle contact and more uniform surfaces; affects firing shrinkage. |

| Surface tension | High surface tension increases flow and bridge formation during sintering. |

| Air pressure | Increases density by removing air in voids under reduced pressure. |

Table 39.2 Stages in firing of porcelain

| Firing stage | Effect of firing |

|---|---|

| Low bisque | Removal of organic matter but minimal shrinkage |

| Medium bisque | Flux flow and shrinkage |

| High bisque | Complete vitrification and surface smoothing |

| Glazing |

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses