Digital Imaging and Processing for Restorations

Dental cad/Cam Systems

CAD/CAM, the abbreviation for computer-aided design/computer-aided manufacturing, describes a process in which digital images or models of objects are created and used for the design and fabrication of prototypes or final products using computer numerical control (CNC) or other fabrication methods such as stereolithography. This process has been used for decades in a variety of industries and has become a popular method in restorative dentistry for creating impressions, cast and dies, and provisional and final restorations. Reports of 10-year follow-up studies for one system have shown good outcomes that are improving with each technological enhancement.

Dental CAD/CAM systems consist of three components:

1. A scanner or digitizing instrument that transforms physical geometry into digital data.

< ?mpslid E6?>< ?mpslid S7?>

< ?mpslid E7?>< ?mpslid S8?>

< ?mpslid E8?>

The two types of CAD/CAM systems for dental offices are acquisition (digital impression) only and scan and mill. Acquisition only systems create digital impressions by capturing images of the preparation and then sending the digital file to a center where a model is made upon which a laboratory technician can fabricate the final restoration. A scan and mill system adds an in-office restoration fabrication device to the digital impression instrument, enabling a restoration to be designed, fabricated, and delivered in one appointment. For the acquisition only system, multiple appointments are required as in conventional indirect restorative care, and a provisional restoration is placed in the interim while the restoration is being fabricated by a laboratory technician. Scan and mill systems offer the convenience of one appointment preparation, impression, fabrication, and delivery, but includes a waiting period while the restoration is milled and the additional cost of the milling machine.

Dental CAD/CAM systems have the following benefits:

• Provide improved precision and consistency

< ?mpslid E9?>< ?mpslid S10?>

• Allow the clinician to visualize the preparation on a computer display from many perspectives

< ?mpslid E10?>< ?mpslid S11?>

• Allow the clinician to design the restoration on a computer while visualizing the opposing dentition

< ?mpslid E11?>< ?mpslid S12?>

< ?mpslid E12?>< ?mpslid S13?>

• Offer instant display and feedback for making corrections immediately

< ?mpslid E13?>< ?mpslid S14?>

• Reduce the environmental impact of disposing the materials required for conventional impressions

< ?mpslid E14?>

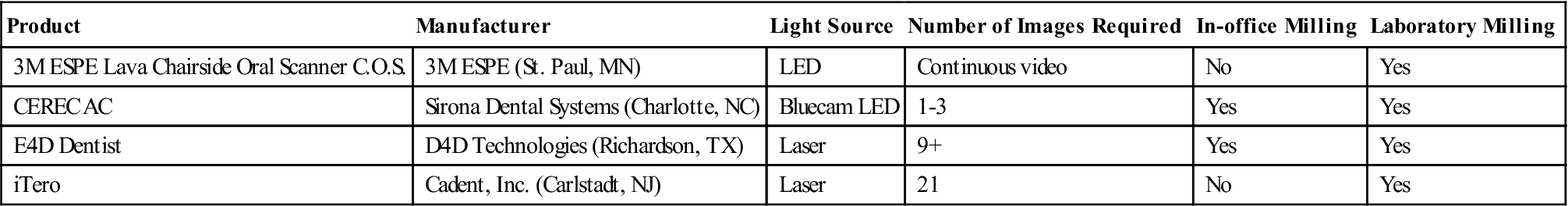

There are several dental CAD/CAM systems currently on the market (Table 14-1). Two of these systems (CEREC AC, Figure 14-1, A, and E4D Dentist, Figure 14-1, B) offer the option of in-office design and milling but also allow design and milling by dental technicians. Two other systems (iTero, Figure 14-2, A, and Lava Chairside Oral Scanner C.O.S., Figure 14-2, B) produce digital impressions that require design and milling at a dental laboratory or milling center. All of these systems can produce models from their digital files.

TABLE 14.1

< ?comst?>

| Product | Manufacturer | Light Source | Number of Images Required | In-office Milling | Laboratory Milling |

| 3M ESPE Lava Chairside Oral Scanner C.O.S. | 3M ESPE (St. Paul, MN) | LED | Continuous video | No | Yes |

| CEREC AC | Sirona Dental Systems (Charlotte, NC) | Bluecam LED | 1-3 | Yes | Yes |

| E4D Dentist | D4D Technologies (Richardson, TX) | Laser | 9+ | Yes | Yes |

| iTero | Cadent, Inc. (Carlstadt, NJ) | Laser | 21 | No | Yes |

< ?comen?>< ?comst1?>

< ?comst1?>

< ?comen1?>

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses