11

Investments and casting

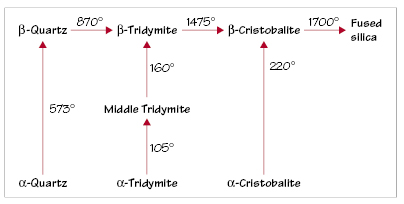

Figure 11.1 Thermal transformations of silica.

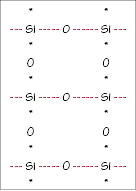

Figure 11.2 Polymerized silica.

Box 11.1 Requirements of investment materials

Easy manipulation

Room-temperature (RT) and elevated temperature strength

Rapid hardening

High-temperature (HT) stability

Thermal expansion over range of temperatures

Sufficient porosity for gas escape

Smooth surface finish

Easy separation from the casting

Nonreacting with the cast metal

Moderate-to-low cost

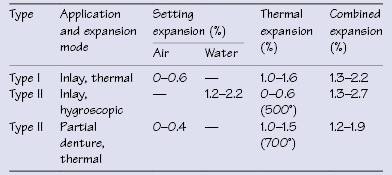

Table 11.1 Expansion requirements for gypsum-bonded investments

Table 11.2 Thermal expansions of crystallographic forms of SiO2

| Crystallographic form | Expansion (%) | Temperature (°C) |

|---|---|---|

| Quartz | 1.4 | 600 |

| Cristobalite | 1.6 | 400 |

| Tridymite | <1 | 600 |

Table 11.3 Effect of manipulation variables on investment expansion

| Factor | Setting and hygroscopic expansion | Thermal expansion |

|---|---|---|

| Increase in W/P ratio | Decreased | Decreased |

| Increased spatulation time | Increased | No effect |

| Increased spatulation rate | Increased | No effect |

| Increased age of investment | Decreased | No effect |

| Delayed immersion | Decreased | — |

| Higher water bath temperature | Increased | — |

| Wax strength | More distortion | Less effect |

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses