Chapter 11

Ceramics and Porcelain Fused to Metal (PFM)

11.1 Introduction

The word ceramic is derived from the Greek word keramos which literally means ‘burnt stuff’ but which has come to mean more specifically a material produced by burning or firing. The first ceramics fabricated by man were earthenware pots used for domestic purposes. This material is opaque, relatively weak and porous and would be unsuitable for dental applications. It consisted mainly of kaolin. The blending of this with other minerals such as silica and feldspar produced the translucency and extra strength required for dental restorations. Material containing these additional important ingredients was given the name porcelain.

Fused porcelain has long been used in the construction of works of art. It can be produced in almost every shade or tint and its translucency imparts a depth of colour unobtainable by other materials. Although the technique for porcelain fusing is exacting it can be initially moulded by hand as a paste and alterations can be made at various stages of the work. It is not surprising, therefore, that dentistry has turned to porcelain for the production of artificial teeth, crowns, bridges and veneers.

Although the favourable aesthetic properties and excellent biocompatibility of porcelain has never been in doubt, its use is somewhat restricted by the relatively brittle nature of the material and the large shrinkage which occurs during processing. Some recent developments offer a potential for overcoming these problems.

11.2 Composition of traditional dental porcelain

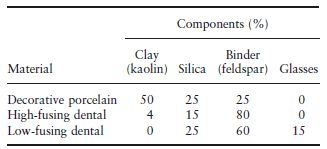

The compositions of the various types of porcelain are summarized in Table 11.1. It can be seen that there are considerable differences in composition between the dental porcelains and decorative porcelain. Indeed, the dental porcelains contain little or no clay and, possibly, would be more aptly described as dental glasses.

Table 11.1 Composition of porcelains.

Kaolin is a hydrated aluminosilicate, Al2O3·2SiO2·2H2O. The set decorative porcelain is essentially a mixture of this with silica, bound together by a flux or binder such as feldspar which is a mixture of potassium and sodium aluminosilicates, K2O·Al2O3·6SiO2 and Na2O·Al2O3·6SiO2. Feldspar is the lowest fusing component and it is this which melts and flows during firing, uniting the other components in a solid mass. The fusion temperature of feldspar may be further reduced by adding to it other low-fusing fluxes such as borax.

Of the two types of dental porcelain, the high-fusing materials fuse in the range 1300–1400°C whilst the low-fusing materials fuse in the range 850–1100°C. The latter materials are by far the more commonly used products.

The precise formulations of dental porcelains vary among the variable products from the proportions given in Table 11.1; however the general trend towards the use of less kaolin (clay) with an increase in the feldspar content in order to improve translucency suggests that dental porcelains should be more correctly described as glasses. The large glassy phases developed by compositions of low kaolin content require closely controlled firing times and temperatures in order to produce an acceptable result.

The powders supplied to the dentist or technician are not just mixtures of the various ingredients. During manufacture the constituents are mixed together and then fused to form a frit. This is broken up, often by dropping the hot material into cold water. It is then ground into a fine powder ready for use.

In the fusion process which takes place during manufacture the flux reacts with the outer layers of the grains of silica, kaolin or glass and partly combines them together. When the technician fuses the porcelain powder, during the production of a crown for example, he simply remelts the fluxes without causing any significant increase in reaction between the flux and the other components.

Porcelain powders are sometimes pigmented in order that natural tooth shades can be matched. The pigments used are normally metal oxides which are stable at the fusion temperature.

Some feldspathic porcelains are supplied as opalescent porcelains. Opalescence is a light scattering effect achieved by the addition of very small amounts of metallic oxides having a higher refractive index and a particle size near to that of the wavelength of light. Since natural teeth can display some opalescence the availability of opalescent porcelains adds further to the ability to match natural tooth appearance in every way.

The use of uranium compounds in dental porcelains to simulate tooth fluorescence is now considered inadvisable. It is not only unnecessary but can give an unnatural appearance under ultraviolet light and, in addition, may create a potential health hazard.

A low-fusing, transparent glass may be used as a glaze over the completed body of the porcelain restoration. The glaze gives the crown an impervious, smooth surface and imparts greater translucency.

A smooth surface can be obtained without using a glaze. By careful control of the furnace temperature, the surface of the normal porcelain will flow and glaze with only a slight rounding of the contours of the restoration. Unfortunately, any overheating will cause gross distortions of the shape.

The porcelain powders are mixed with water to produce a plastic mass of material which can be moulded and carved before firing. To improve the working properties a binder such as sugar or starch is added to some powders.

11.3 Compaction and firing

The aqueous plastic mass of porcelain particles is compacted as much as possible onto a platinum foil matrix. This reduces the size of the spaces between the particles and thus reduces firing shrinkage. Powders consisting of a mixture of particle sizes compact more easily than those with particles of one size only.

The moulded crown may be lightly vibrated, thus helping to settle the powder particles and bring excess water to the surface, where it is blotted by an absorbent cloth. Alternatively, the powder may be ‘patted’ with a spatula to achieve the same effect.

A well-compacted crown not only reduces firing shrinkage but also shows a regular contraction over its entire surface, thus maintaining the original form on a slightly reduced scale.

Following compaction, the next stage involves porcelain ‘firing’. A porcelain furnace consists, essentially, of an electrically heated muffle with a pyrometer which indicates the temperature in that part of the muffle where the porcelain is placed. Most modern porcelain furnaces allow firing under vacuum. This has the effect of reducing the porosity within the finished material from around 4.6% to about 0.5%.

If the freshly compacted, wet structure is placed directly into a hot furnace it will evolve steam rapidly and crumble or even explode. The normal procedure, therefore, is to dry the wet structure in a warm atmosphere before placing into the hot furnace.

At the elevated temperatures of the furnace, the starch or sugar binder ignites and the surface of the structure blackens. The door of the furnace is left slightly ajar during this stage to allow the products of combustion to escape. The furnace door is then closed and firing is completed. Shrinkage takes place as the fluxes bind the particles together causing a uniform inward contraction of the whole mass. Further additions of fresh material may be made at this stage before glazing. Whenever porcelain work is heated or cooled the process must be carried out slowly. Porcelain is a poor conductor of heat and is brittle. Rapid cooling would result in cracking and loss of strength.

The accuracy of fit is maintained by building up the porcelain on a platinum foil which has been closely adapted to the die. The firing shrinkage which occurs does not therefore cause a great discrepancy in the accuracy of fit, since the shrinkage occurs inwards towards the platinum foil and the foil itself is not affected by firing. Before cementation, the platinum foil is removed from the inner surface of a crown to create about 25 μm of space for cementation.

The porcelain surface is generally glazed as mentioned in Section 11.2. This has the dual effect of improving appearance and removing surface imperfections, particularly porosities, which may adversely affect mechanical properties. The use of porcelain for constructing inlays is a most exacting technique because, in this case, firing shrinkage has a direct effect on the fit of the inlay. For this reason the porcelain inlay was a very rare restoration. This situation has changed with the development of castable ceramics, shrink-free materials, the more widespread availability of refractory materials on which porcelain restorations can be manufactured, and CAD–CAM systems.

11.4 Properties of porcelain

Aesthetically, porcelain is an almost perfect material for the replacement of missing tooth substance. It is available in a range of shades and at various levels of translucency such that a most life-like appearance can be achieved. The inner layer of the porcelain crown, for example, is normally constructed from a fairly opaque ‘core’ material. This is overlaid with a more translucent ‘dentine’ material with a final coating of translucent ‘enamel’ porcelain forming the outermost layer.

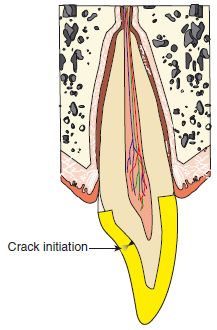

Porcelain is a very rigid, hard and brittle material whose strength is reduced by the presence of surface irregularities or internal voids and porosities. Finegrained powders give more uniform surfaces than coarser grains, and firing at reduced pressures can reduce porosity. The formation of superficial cracks due to thermal stresses are best avoided by slow cooling from the firing temperature. Fracture can be initiated from small surface scratches caused by grinding and these should be eliminated by smoothing or by further fusing. Cracks in porcelain crowns invariably emanate from the inner, unglazed fitting surface and propagate outwards towards the exposed surface material as illustrated in Fig. 11.1. The brittleness of dental ceramics is compounded by their tendency to undergo static fatigue. This is a time-dependent decrease in strength, even in the absence of any applied load. The process is thought to occur through alkaline hydrolysis of Si–O groups within the porcelain structure. Alkalinity within the material results from a solubilization of Na2O and K2O which forms part of the feldspathic component of porcelain. The weakening is further accelerated by dynamic mechanical loading and the whole process has been likened to stress corrosion cracking which can occur with metals and alloys. Attempts to overcome some of these problems involved reducing the proportions of Na2O and K2O within the materials.

Fig. 11.1 Diagram illustrating the initiation and propagation of a crack from the inner surface of a porcelain crown.

Tooth preparation for all porcelain crowns needs to be designed to reduce the possibility of producing areas of high stress within the finished restoration. All internal line angles should be rounded and care is required to ensure that there are no areas of sudden change in thickness of porcelain. The gingival finishing margin should be a smooth shoulder (i.e. without steps) and the finishing angle should be 90° to the root surface.

As we have said earlier, fracture in ceramic materials occurs through crack initiation and propagation from surface flaws. In order for cracks to grow the material in the region of the crack tip must be placed under tension. Hence, one method of strengthening ceramics is to generate compressive stresses in these regions. This can be achieved by one of two mechanisms. First, ion strengthening can be used. This involves soaking the fired material in a molten salt in order to allow ion exchange at the surface. If sodium ions are partially replaced by potassium ions, the latter occupy a greater volume and effectively create compressive stresses in the surface layer of the material. Such procedures can be carried out in a dental laboratory using an ion-exchange paste which is painted onto the surface. The ion-exchange procedure is achieved by placing the treated ceramic material in a dental laboratory oven in order to create the conditions under which diffusion can occur.

A second method for strengthening involves putting the outer layer into compression through thermal strengthening. During firing the outer layer solidifies first as it cools more rapidly. The poor thermal conductivity of the material dictates that the inner part of the material remains liquid for longer. When the inner material finally solidifies it shrinks and sets up a compressive stress in the outer layer. This method of strengthening can occur during the initial firing of the ceramic or during subsequent heat tempering.

The relatively poor mechanical properties of porcelain can be improved using alumina, or metal supporting structures. These are discussed in the next sections.

The hardness of porcelain (Table 2.2) contributes to its ability to resist forces of abrasion but may give rise to some concern over the potential for porcelain restorations to abrade the opposing teeth. It has been shown, however, that the wear of enamel by ceramic restorations cannot easily be predicted by the hardness of the ceramic. Some extremely hard ceramics seem to produce lower enamel wear compared with softer materials. The shape of crystalline inclusions within the ceramic appears to be an important factor in determining the abrasive potential of a ceramic material. The appearance of ceramic restorations depends in part on the surface gloss which can be produced using a glaze or by polishing. The hardness of porcelain dictates that polishing using abrasives should be difficult. However, different porcelains respond differently to abrasive polishing. Carefully controlled polishing with a fine abrasive such as pumice can give a satisfactory surface with some materials. From a clinical standpoint a polished porcelain surface will accumulate more plaque than a glazed surface. Hence porcelain at crown margins should be glazed whenever possible.

Porcelain has excellent thermal properties and is a particularly good thermal insulator. This fact is of importance when gross amounts of enamel and dentine are to be replaced and the residual layer of dentine may be of minimal thickness.

Correctly formulated porcelain is very resistant to chemical attack, being unaffected by the wide variations of pH which may be encountered in the mouth.

11.5 Alumina inserts and aluminous porcelain

The major disadvantage of porcelain is brittleness and this is the factor which most limits its use. Several methods are available which are aimed at preventing the formation or propagation of cracks on the inner surface of porcelain restorations.

One approach is to use a core of pure alumina on which the porcelain crown is constructed. Alumina is a very hard, opaque material which is less susceptible to crack propagation than porcelain. Another approach to strengthening involves the use of pure alumina inserts. These may be in the form of small sheets of alumina which are generally placed palatally in a crown in order to strengthen without impairing the appearance.

Powdered alumina may be added to porcelain in order to achieve a significant strengthening. The mechanism of strengthening is that the alumina particles act as ‘crack stoppers’ preventing the propagation of a crack throughout the body of the porcelain (Fig. 11.2a). This improvement of properties is achieved not only as a result of the good mechanical pr/>

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses