CHAPTER 11 Case Presentations

Alternatives for Final Framework Designs

Hybrid versus Profile Prostheses

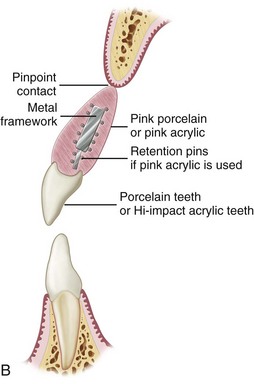

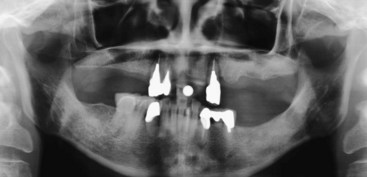

The Toronto bridge was a “high water” design because the abutments available at the time were standard abutments, which, by design, were at least 0.5- to 1-mm supragingival. Therefore, the final design of the prosthesis left a gap between the intaglio surface of the prosthesis and the crest of the ridge. This type of design was functional for the edentulous mandible. When turned upside down and used for the edentulous maxilla, however, it left a lot to be desired. The gap allowed air to escape during speech and caused mispronunciation of dentoalveolar sounds. Proper pronunciation requires a palatal seal between the prosthesis and the palatal soft tissues (Figures 11-1 and 11-2).

The Profile Prosthesis: Gold Framework

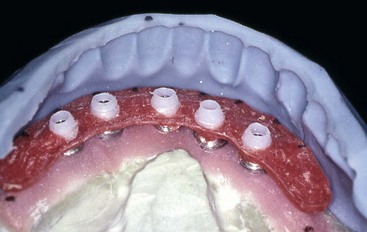

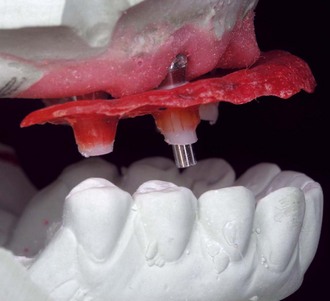

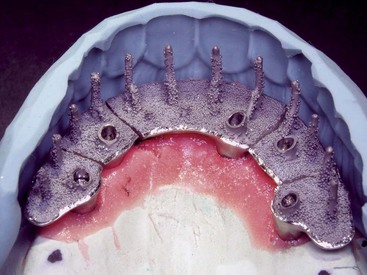

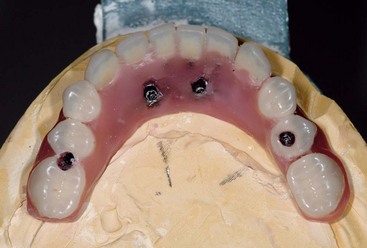

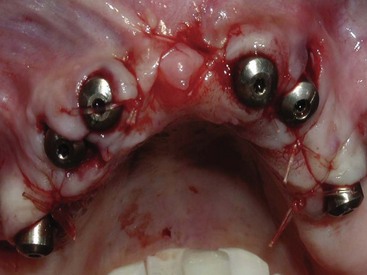

The following section demonstrates the various steps in the fabrication of a maxilla and/or mandibular profile prostheses (Figures 11-3 to 11-17).

FIGURE 11-4 The pink acrylic completely wraps around the metal substructure of this profile prosthesis.

FIGURE 11-11 Proper positioning of the support rods for support and retention of the maxillary teeth.

Titanium Framework: Procera Implant Bridge

(Figures 11-18 to 11-20)

FIGURE 11-19 Hidden transition line during animation suggests a positive outcome for a final profile prosthesis.

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses