Additional Information on Instruments and Equipment for Tooth Preparation

Sharpening Hand Instruments

Mechanical Sharpeners

The Rx Honing Machine (Rx Honing Machine Corp, Mishawaka, IN) is an example of a mechanical sharpener (Online Fig. 23-1). This instrument moves a hone in a reciprocating motion at a slow speed, while the instrument is held at the appropriate angulation and supported by a rest. This is much easier than holding the instrument at the proper angulation while moving it relative to the hone. Interchangeable aluminum oxide hones of different shapes and coarseness are available to accommodate the various instrument sizes, shapes, and degrees of dullness. Restoration of the cutting edge is accomplished more easily and in less time than by other sharpening methods. This type of sharpener is also very versatile and, with available accessories, can fill almost all instrument sharpening needs.

Principles of Sharpening

1. Sharpen instruments only after they have been cleaned and sterilized.

2. Establish the proper bevel angle (usually 45 degrees) and the desired angle of the cutting edge to the blade before placing the instrument against the stone, and maintain these angles while sharpening.

3. Use a light stroke or pressure against the stone to minimize frictional heat.

4. Use a rest or guide, whenever possible.

5. Remove as little metal from the blade as possible.

6. Lightly hone the unbeveled side of the blade after sharpening, to remove the fine bur that may have been created.

7. After sharpening, resterilize the instrument along with other items on the instrument tray setup.

8. Keep the sharpening stones clean and free of metal cuttings.

Mechanical Sharpening Techniques

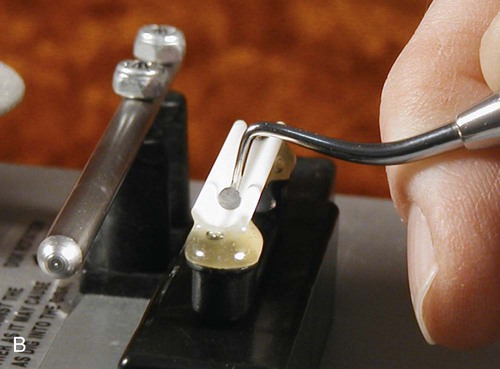

When chisels, hatchets, hoes, angle formers, or gingival margin trimmers are sharpened on a reciprocating honing machine (i.e., sharpener), the blade is placed against the steady rest, and the proper angle of the cutting edge of the blade is established before starting the motor. Light pressure of the instrument against the reciprocating hone is maintained with a firm grasp on the instrument. A trace of metal debris on the face of a flat hone along the length of the cutting edge is an indication that the entire cutting edge is contacting the hone (see Fig. 23-1, B).

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses