Introduction

The aim of this study was to evaluate the surface roughness and morphology of enamel with a surface roughness tester and scanning electron microscopy after the removal of metal brackets and polishing.

Methods

Ten orthodontic patients were selected for the study. At the conclusion of orthodontic treatment, their metal brackets were removed. For each patient, teeth on one side of the mouth were randomly chosen for finishing and polishing with aluminum oxide discs (n = 10). Teeth on the other side were finished with multilaminated carbide burs (n = 10). Dental replicas (before and after tooth polishing) were obtained with epoxy resin. Three surface roughness measurements were made in different directions with an angle of 120° among them, and a mean for each dental replica was calculated. The roughness data were statistically evaluated by repeated-measurements analysis of variance. Three specimens from each group were also used for scanning electron microscopy analysis.

Results

After resin removal, the average roughness in the carbide bur group (0.31 μm) was significantly greater than that in the aluminum oxide disc group (0.25 μm).

Conclusions

The aluminum oxide disc polishing system resulted in less enamel roughness than did the multilaminated carbide bur system.

Highlights

- •

Surface roughness was examined in vivo after debonding the maxillary central incisors.

- •

The aluminum oxide disc polishing system resulted in less enamel surface roughness.

- •

Roughness values were similar between untouched enamel and enamal polished by carbide burs.

Since 1970, bonding of orthodontic brackets to tooth enamel has become an accepted clinical technique. A typical bonding procedure involves alteration of the enamel surface by acid etching, followed by the application of adhesive primer and resin. Adhesive systems for bracket bonding play a key role in fixed orthodontic therapy. Accordingly, many research teams have evaluated the bond strength of the adhesive interface, paying special attention to the adhesive or bracket type and the enamel preconditioning method. Relevant factors in bracket debonding and subsequent polishing of the enamel surface have also been investigated.

Incorrect removal of the brackets or adhesive can lead to permanent damage of the enamel and an extended time for debonding. The final procedure in returning the enamel surface to the original pretreatment condition involves the removal of all attachments and remaining resin from the tooth surfaces. Researchers have tested different techniques for resin removal and enamel polishing to prevent iatrogenic damage. These techniques include scraping with a scaler or band-removing plier or a tungsten carbide bur in a contra-angle hand piece (the most common method), and the use of abrasive discs. Thus, each debonding procedure can result in variable surface quality according to the instruments used and the different degrees of enamel loss.

Esthetics is a primary consideration for patients seeking orthodontic treatment, and many treatment options are available that maximize the likelihood of an attractive outcome. The form and brightness of the maxillary anterior teeth are important for both dental and facial esthetics. These teeth should be treated to restore the optimal dentolabial relationship in harmony with the overall facial appearance. However, little scientific data are available in the dental literature to use as a guide for defining the proper form and brightness of the anterior teeth or for determining their normal relationships. The brightness of the buccal surface must be restored after orthodontic treatment, a goal that may not be possible to achieve with rough surfaces.

Surface roughness after debonding can be measured in several ways, including linear contact measurement and visual analysis through scanning electron microscopy (SEM). Many laboratory studies have examined the surface roughness after debonding, but in-vivo studies were not found. Fewer studies have been conducted in the maxillary central incisors. Thus, the aim of this study was to evaluate in vivo the surface roughness and morphology of the enamel using a surface roughness tester and SEM after the removal of metal brackets from the maxillary central incisors. The null hypothesis was that the surface roughness and the morphology of the areas of untouched enamel would not differ from those in areas that were polished by an aluminum oxide disc or a carbide bur.

Material and methods

This study was approved by the research ethics committee of the University of North Paraná in Brazil. For the study, 10 patients (5 male, 5 female) were selected, ranging in age from 14 years to 21 years 7 months (mean, 17 years 6 months). No patient had any caries, restorations, history of trauma, bruxism, or cracks on the maxillary incisors. The middle third of the buccal face of all teeth was etched with 37% phosphoric acid gel (Condac 37; FGM, Joinville, Paraná, Brazil) for 30 seconds, rinsed with air-and-water spray, and air dried for 20 seconds. One layer of adhesive (Adper Single Bond 2; 3M ESPE, St Paul, Minn) was applied to the etched area. Then stainless steel standard maxillary incisor brackets (Roth; Morelli, Sorocaba, São Paulo, Brazil) were positioned and firmly bonded to the teeth with Filtek Z100 (3M ESPE). A microbrush was used to remove any excess.

Bonding of the brackets was achieved by light activation with an Ultraled (Dabi Atlante, Ribeirão Preto, São Paulo, Brazil) light-emitting diode device at an irradiance of 800 mW/per square centimeter. The edge of each bracket was exposed to the light-emitting diode for 10 seconds, with a total exposure time of 40 seconds. In total, 10 brackets were bonded on each maxillary central incisor.

The patients’ orthodontic treatment duration ranged from 15 to 28 months (mean, 21.5 months). After treatment, the brackets were removed with pliers (ETM 346; Ormco, Orange, Calif). Then prophylactic procedures were performed with pumice and a Robinson brush in a hand piece (Dabi-Atlante) at a low speed. The teeth were washed, dried, and impressed with Aquasil Ultra polyvinylsiloxane (DENTSPLY Caulk, Milford, Del) by adding in dual phase (putty/wash) with a 1-step impression technique (Ultra-light, Aquasil Ultra XLV and Putty, Aquasil Easy Mix Putty; DENTSPLY Caulk). The mold was cast with epoxy resin (20-8130-032; Buehler, Lake Bluff, Ill).

The adhesive remnant index (ARI) of the dental replicas (of the debonded teeth with remaining resin) was analyzed with an optical microscope (SZM; BEL Engineering, Milan, Italy) at 40 times magnification. The ARI was used to classify the failure mode as follows: 0, no bonding resin left on the tooth; 1, less than half of the bonding resin left on the tooth; 2, more than half of the bonding resin left on the tooth; and 3, all bonding resin left on the tooth, with a distinct impression of the bracket mesh.

For each patient, one side of the mouth was randomly selected, and the teeth on that side were finished and polished with aluminum oxide discs (Sof-Lex; 3M ESPE) (n = 10). The discs were used at low rpm under intermittent cooling, in decreasing order of abrasiveness for 20 seconds each, until a visibly smooth and polished surface was obtained. On the other side, the teeth were finished with a multilaminated carbide bur (FF 9642; JET, Morrisburg, Ontario, Canada) (n = 10), also used at low rpm under intermittent water cooling until a visibly smooth and polished surface was obtained (80 seconds). After the removing the remaining resin, new replicas with polished teeth were obtained with the aforementioned procedures.

For the surface roughness measurements, 3 sets of dental replicas were tested: after debonding and before polishing (initial conditions), after polishing with the aluminum oxide disc system, and after polishing with the carbide bur system. The surface roughness was measured with a surface roughness tester (SJ 400; Mitutoyo, Kawasaki-Shi, Kanagawa, Japan) at a speed of 0.05 mm per second, with a length of 2.5 mm and a cutoff of 0.25 mm. It was verified that the ARI values of the 2 maxillary central incisors were similar (±0.05 μm). Three measurements were made in different directions with an angle of 120° among them, and a mean for each dental replica was calculated.

For the initial condition (before polishing), the average (mean) surface roughness values in the areas of untouched enamel close to adhesive remnants that were not covered by the bracket or previously acid etched were determined for each specimen (n = 10). Surface roughness measurements were also made in the 2 experimental groups after resin removal.

Statistical analysis

Statistical analysis was performed with the Minitab 16 for Windows 8 (Minitab, State College, Pa). The distributions of the measurements were investigated with the Kolmogorov-Smirnov normality test; then parametric tests were used. Data for roughness values were statistically evaluated by repeated measurements analysis of variance at the 5% significance level (α = 0.05) for the areas of untouched enamel and each resin removal method (experimental groups).

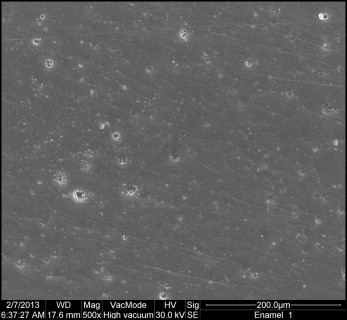

Three replicas from each group were analyzed by SEM (JSM 5600; Jeol, Peabody, Mass). The specimens were gold sputtered to a thickness of about 50 Å in a vacuum evaporator (SCD 050; Oerlikon Balzers, Balzers, Liechtenstein). Photomicrographs at 500 times magnification were taken in representative areas of the surfaces.

Results

Results for the ARI scores are shown in Table I . For both experimental groups, an ARI score of 3 was predominant. The surface roughness test results are depicted in Table II (power of statistical test, 0.83). After resin removal, the surface roughness of the carbide bur group (0.31 μm) was higher than that of the aluminum oxide disc group (0.25 μm) ( P <0.001). The surface roughness value before resin removal in the areas of untouched enamel (0.37 μm) was not significantly different from the surface roughness value in the carbide bur group ( P = 0.14).

| Experimental group | ARI scores (%) | |||

|---|---|---|---|---|

| 0 | 1 | 2 | 3 | |

| Aluminum oxide | 0 | 0 | 10 | 90 |

| Carbide bur | 0 | 10 | 0 | 90 |

| Aluminum oxide (n = 10) | Carbide bur (n = 10) | P value | |

|---|---|---|---|

| Mean ± SD | Mean ± SD | ||

| Areas of untouched enamel | 0.38 ± 0.06 | 0.37 ± 0.07 | 0.90 |

| After resin removal | 0.25 ± 0.02 | 0.31 ± 0.07 | <0.001 |

| P value | <0.001 | 0.14 |

Figures 1 through 3 show the SEM results (magnification, 500 times) for representative areas of the enamel surfaces in each group. Figure 1 shows an SEM micrograph of an area of untouched enamel before resin removal. Grooves are apparent and were probably due to the prophylaxis performed with pumice. Figure 2 shows an SEM micrograph of enamel that was polished by an aluminum oxide disc; no grooves are apparent. Figure 3 shows an SEM micrograph of enamel treated with a carbide bur. There are slightly more grooves in this image compared with the initial condition.