Introduction

The objective of this study was to quantify the properties of commercially available nickel-titanium open-coil springs.

Methods

Eleven springs from 3 manufacturers were tested 5 times over a 12-week period. A universal testing machine was used to measure the force generated when open-coil springs were compressed to half of their original length and then gradually allowed to decompress.

Results

The average forces generated at the initial recording session for uniformly wound springs from GAC International (Bohemia, NY) and 3M Unitek (Monrovia, Calif) were 19.3% to 42.7% and 9.7% to 38.8% below the manufacturers’ labeled force levels, respectively. GAC’s 100-, 150-, and 200-g stop-wound coils demonstrated statistically and clinically significant stepwise force degradation over the 12-week experimental period ( P <0.0001). GAC’s uniformly wound light (100 g) coils generated the lowest load-deflection ratios (23.7 g/mm).

Conclusions

Open coils might need to be compressed by more than one-third of their original length to produce the labeled forces. Uniformly wound coils generally produce lower load-deflection ratios and maximum forces, which are generally more acceptable for tooth movement.

Nickel-titanium (NiTi) coil springs can produce continuous, light forces over a large range of activation. They have significantly limited the use of stainless steel coil springs as force-generating modules in orthodontics, since the latter can only produce initial forces of high magnitude that quickly dissipate even with small deactivations. Von Fraunhofer et al compared the forces generated by open-coil springs fabricated from heat-activated superelastic NiTi (Sentalloy, GAC International, Bohemia, NY) and stainless steel (3M Unitek, Monrovia, Calif). The Sentalloy open-coil springs (0.010 × 0.035 in) produced forces of 55 to 70 g with 9 mm of activation, whereas the stainless steel springs (0.010 × 0.030 in) produced forces of 200 g when activated by just 1 mm.

The variables that determine the force produced by an open-coil spring are its lumen size, wire type, and wire size. All other things being equal, the larger the lumen size and the smaller the wire cross-section, the lighter the force produced, for the same activation. Another important physical parameter when considering biomechanical properties of open-coil springs is the winding pitch. Pitch is the distance between individual coils in the spring. As the pitch decreases, the amount of wire incorporated into the wire is increased. Therefore, tightly wound coils (small pitch) generally produce lower forces.

Schneevoight et al investigated 32 NiTi open-coil springs from 7 manufacturers, including GAC and 3M Unitek. Segments of coil springs 20 ± 2 mm long were tested at 27°C, 37°C, and 47°C with a universal testing machine. The springs were compressed maximally. Only GAC Sentalloy springs demonstrated constant forces on the unloading curve. Raising the temperature caused an increase of the magnitude at which the force plateaued by 0.4 to 0.9 N, and a shortening of the plateau width by 4% to 15%. The plateau magnitudes varied by as much as 18% between batches.

Manhartsberger and Seidenbusch evaluated uniformly wound Sentalloy coil springs from GAC and found that the generated forces were actually greater than the labeled forces. According to the manufacturer, the coils should have produced the labeled forces when they were compressed up to 80% of their original length and maintained these forces during deactivation. The authors found that the Sentalloy open-coil springs with a suggested force delivery of 150 g actually produced 300 g of force when compressed to 80% of their original length. They concluded that a new activation range should be determined for Sentalloy springs, and they suggested activation ranges for each force level of open and closed coils.

Studies of closed-coil NiTi springs have shown similar results to the study of Manhartsberger and Seidenbusch. Chow found that closed coil springs manufactured by GAC and 3M Unitek produced lower generated forces than the labeled values (31% and 36% lower, respectively). In the same study, springs manufactured by TP Orthodontics (LaPorte, Ind) produced forces that were 24% higher than the manufacturer’s labeled values. The 3M Unitek springs produced the most constant forces throughout an activation range of 13 mm and, therefore, were considered the most ideal for clinical tooth movement.

The objectives of this study were to quantify the biomechanical properties of commercially available NiTi open-coil springs from 3 manufacturers and compare them with their manufacturers’ specifications.

Material and methods

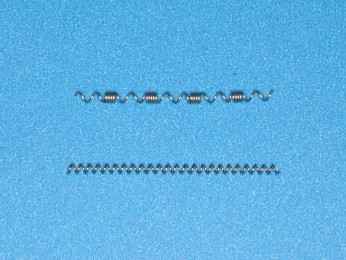

Eleven open-coil springs from 3 manufacturers (3M Unitek, TP Orthodontics, and GAC International) were selected. Springs of 3 force levels and 2 designs (uniformly wound and stop-wound) were tested ( Fig 1 , Tables I and II ). The following parameters were measured for each spring: maximum force, average force during deactivation, load-deflection ratio, and force degradation over a 12-week period in a simulated oral environment. Based on the desired power of the study (approximately 80%, with an estimated magnitude of difference of 10% at a level of significance of P <0.05), a sample size of 20 coil springs for each force level and each design was deemed adequate.

| Length | Inner diameter | Labeled force level (catalog number) | |

|---|---|---|---|

| 3M Unitek Nitinol | 7 in | 0.030 in | Light, 100 g (345-100) Medium, 200 g (345-200) Heavy, 275 g (345-275) |

| GAC International Sentalloy | 0.59 in | 0.035 in | Light, 100 g (10-000-09) Heavy, 200 g (10-000-07) Extra heavy, 300 g (10-00-17) |

| Length | Inner diameter | Labeled force level (catalog number) | |

|---|---|---|---|

| TP Orthodontics Reflex |

7 in | 0.35 in (0.012-in wire) 0.55 in (0.010-in wire) |

(210-508) (210-515) |

| GAC International Sentalloy |

7 in | 0.035 in | Light, 100 g (10-000-21) Medium, 150 g (10-000-22) Heavy, 200 g (10-000-23) |

The uniformly wound coils from GAC came in lengths of 15 mm. According to GAC, the springs could be compressed by 12 mm (down to 3 mm) and still deliver the labeled forces. All other springs came in 7-in segments, with no manufacturer-recommended amount of compression.

All spring segments were cut to a length of 10 mm. This length was chosen for several reasons. First, 10 mm was considered an approximate length of coil used clinically to expand an interdental space to the full width of a tooth. Second, the uniformly wound coils could have been cut to any length, whereas the stop-wound coils had to be cut within the closed (tightly wound) regions of the coil. A 10-mm length was one that could apply to both stop-wound coil designs from the 2 manufacturers.

A universal testing machine (model 4301, Servo Hydraulic, Instron, Canton, Mass) was used for all measurements. The static load cell was set at a constant 50 N. The speed with which the springs were compressed was set at 15 mm per minute. The springs were compressed to half of their original relaxed lengths (from 10 to 5 mm). This maximum amount of compression was chosen based on the methodology of Chaconas et al. The testing machine was programmed to cycle once, by compressing the springs from 10 to 5 mm and then to return to the original length at the same speed.

The data were automatically recorded on a personal computer by using Lab View graphical programming for instrumentation software (version 5.0, National Instruments, Austin, Tex). The outputs were compiled as Excel files (Microsoft, Redmond, Wash). Values were recorded to .001 mm and .001 N (1 N = approximately 100 g).

The testing machine was fitted with a customized base that was bolted in place. The base was designed to allow the springs to be compressed along a length of wire. During the testing, springs were compressed on a 0.020-in diameter wire, which was attached to a custom-designed crosshead ( Fig 2 ).

Between tests, the springs were kept compressed to 70% of their original length (7 mm) in custom-fabricated compression racks ( Fig 3 ). Each compression rack could hold 40 springs. The racks were submerged in physiologic saline solution (0.9% sodium chloride) and stored in a sealed plastic container (Ziploc, S. C. Johnson & Son, Racine, Wis). The sealed containers were stored at 37°C in an incubator unit (Isotemp Incubator, senior model 205, Fisher Scientific, New York, NY).

The springs of various force groups were tested in the same order at every testing session. Testing sessions were performed at the beginning of the experiment (T0), at 24 hours (T1), 4 weeks (T2), 8 weeks (T3), and 12 weeks (T4). One investigator (A.B.) completed all testing sessions.

The testing machine produced 2000 to 2500 data points per recording. The data sets were converted to Excel files. Only the data collected during the decompression (deactivation) of the springs were used to evaluate the force characteristics of the springs.

Statistical analysis

The mean forces and standard deviations were calculated for each group of springs. The mean maximum force, the mean average force, and the mean load-deflection ratio were also calculated. The average force was defined as the force magnitude produced between 20% and 80% compression during unloading (deactivation) of the springs.

The Student t test was used to determine whether the measured average force was significantly different from that labeled by the manufacturer. The significance level was set at P <0.05. Repeated-measures analysis of variance (ANOVA) was used for intragroup comparisons between test sessions (T0, T1, T2, T3, and T4) and intergroup comparisons between manufacturers. This comparison only involved springs from GAC and 3M Unitek, since TP Orthodontics springs were not labeled with specific force values.

In each group of springs, comparisons were made of mean maximum force, mean average force (20%-80%), and load-deflection ratio (slope). The Prasad-Rao-Jeske-Kackar-Harville post-hoc test was then performed to determine differences between testing sessions and manufacturers. Repeated-measures ANOVA was also used to determine whether there were significant differences between GAC stop-wound and GAC uniformly wound coils at T0. The significance was set at P <0.05.

Force degradation was considered clinically significant if there was a total decline in measured force over the 3 months of 10% or more. The manufacturers’ labels were described as clinically accurate if the measured mean force was within 10% of the labeled force.

Results

All springs had average force values that were significantly lower than the manufacturers’ values at T0 ( Tables III and IV ). The 3M Unitek 100-g springs produced average forces that were only 10 g lower than the labeled value. The GAC stop-wound 200-g springs produced average forces that were less than half of the labeled value.