Introduction

In this study, we aimed to assess the surface characteristics and the biomechanical stability of miniscrews with an anodic oxidized surface compared with machined surface miniscrews in beagle dogs.

Methods

Self-drilled, titanium-aluminum-vanadium alloy miniscrews with an anodic oxidized surface (n = 48) or a machined surface (n = 48) were placed into the mandibles of 12 beagle dogs. The surface characteristics of both types of miniscrews were analyzed before implantation with scanning electron microscopy and atomic force microscopy. Insertion torque was measured during placement of all 96 miniscrews. Half of the implants in each group (24 specimens per subgroup) received 200 to 250 g of tensile force for 3-week or 12-week loading periods. Removal torque was measured in 12 specimens of each subgroup, and bone-implant contact and bone volume were quantified in the other 12 specimens of each subgroup.

Results

Atomic force microscopy measurements demonstrated that the anodic oxidized surface miniscrews had significantly higher roughness parameters than did the machined surface miniscrews ( P < 0.001). The 2 types of miniscrews were not significantly different in insertion and removal torque values or in bone-implant contacts and bone volumes, regardless of the loading period.

Conclusions

Anodic oxidized miniscrews have different surface roughness profiles but no clinically significant superiority in biomechanical stability compared with machined surface miniscrews.

Highlights

- •

Anodic oxidized miniscrews had greater surface roughness than did machined miniscrews.

- •

The 2 types of miniscrews were not significantly different in insertion and removal torques.

- •

The 2 types of miniscrews were not significantly different in bone-implant contact ratio and ratio of bone volume to total volume.

- •

The stability of anodic oxidized miniscrews was not better than machined miniscrews.

The success rates of orthodontic miniscrews in clinical practice range from 83.9% to 93.3%. These rates are relatively low considering that dental implant success rates are 95% and higher. The failure of a miniscrew is associated with host factors (inflammation of the peri-implant tissues or a high mandibular plane angle with thin cortical bone) and the location of implantation (in the posterior mandible or surrounded by nonkeratinized mucosa).

To improve the clinical success of miniscrews in unfavorable conditions, various studies have tested different surface modifications because an increased surface area directly affects cell function and can be enhanced to accelerate osseointegration between the titanium dioxide layer of an implant and surrounding bony tissue. Kim et al reported that sandblasted, large-grit, and acid-etched treated miniscrews exhibited higher removal torque values than those with a smooth machined surface. Cho et al reported that miniscrews coated with titanium and nitrogen by plasma ion implantation also had a similar mechanical stability to sandblasted, large-grit, and acid-etched miniscrews.

Another method for modifying the surface topography of miniscrews is an anodic oxidation technique that creates an adherent oxide coating on the titanium surface with microporosity and nanoporosity. This characteristic distribution of micropores and nanopores can be used as a platform for drug delivery. Previous studies have reported that anodic oxidized miniscrews decrease insertion damage to surrounding tissues and improve mechanical stability in the early phase of retention. However, the authors of these studies did not perform histomorphometric analyses to evaluate the degree of bone-implant contact.

The purpose of this animal-based study was to assess the surface characteristics and the biomechanical stability of anodic oxidized miniscrews. The null hypothesis was that the biomechanical stability would be similar between anodic oxidized and the machined surface miniscrews, regardless of the loading period.

Material and methods

Twelve adult male beagle dogs (age, 12-15 months; weight, 10-13 kg) were used in this study. The dogs’ purchase, selection, and management, and the experimental procedures were conducted according to conditions prescribed by the animal laboratory at Yonsei University Medical Research Center in Seoul, Korea. This study was approved by the research ethics committee of the institutional animal care and use committee of Yonsei University Health System (protocol 09-162).

The 12 beagles were divided into groups that received anodic oxidized and machined surface miniscrews using a random block design to prevent individual-related and location-related discrepancies. A total of 96 miniscrews were used (8 miniscrews per dog). We used a self-drilled, cylinder type, orthodontic titanium-aluminum-vanadium alloy miniscrew (diameter, 1.45 mm; length, 7 mm; single-threaded; Biomaterials Korea, Seoul, Korea). After a pilot study, the sample size was calculated (G*Power 3; University of Düsseldorf, Düsseldorf, Germany) with a significance level of 0.05, a power of 80%, and an effect size of 0.4 to detect a removal torque difference between the anodic oxidized and machined surface miniscrews and between the experimental periods. The roughness of the anodic oxide layers of titanium was produced by immersing the miniscrews in an electrolyte solution that contained 0.4 mol/L of calcium acetate and 0.04 mol/L of β-glycerophosphate disodium salt pentahydrate, and applying 250 V for 3 minutes.

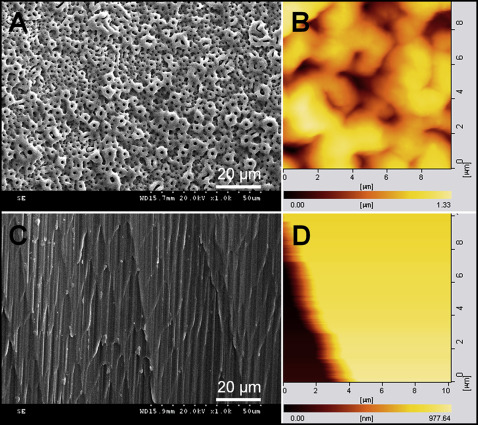

The miniscrew surfaces were evaluated with scanning electron microscopy at magnifications of 1000 times (S3000N; Hitachi, Tokyo, Japan) and with atomic force microscopy (NPX 200; Seiko Instruments, Chiba, Japan). Based on data from a previous study, 3 unused miniscrews of each type of surface topography were selected by simple random sampling and analyzed to detect significant differences of the mean roughness values of the groups. On each miniscrew, 3 threads were selected at random and scanned along their circumference in 3 areas, yielding 9 measurements for each type of surface. To characterize the surfaces of the 2 types of miniscrews, 54 images were obtained. The measured area was 10 × 10 μm for all measurements. The roughness profile was defined by the arithmetic mean of the distances of departure from the midline, the root mean square parameter corresponding to the arithmetic mean of the distances of departure from the midline, and the average height difference between the 5 highest peaks and the 5 lowest valleys.

The experimental animals were injected subcutaneously with 0.05 mg per kilogram of atropine, followed by intravenous xylazine at 2 mg per kilogram (Rompun; Bayer Korea, Seoul, Korea) and ketamine 10 mg per kilogram to induce general anesthesia. Anesthesia was maintained with 2% enflurane. Each animal’s temperature was maintained with a heating pad, and vital signs were monitored with an electrocardiogram.

Before placement, a 2-mm gingival incision was made at the implantation site to prevent tissue impingement under saline solution irrigation. The insertion of each miniscrew followed a random block design, and the positions were equivalently distributed between the groups ( Table I ). The miniscrews were placed in the intraradicular spaces of the first molar, the fourth premolar, the third premolar, and the second premolar in the mandible. The maxilla was not used in this study because of the possibility of sinus perforation. The placement was performed manually by 1 investigator (J-Y.C.) with 90 angulations to the gingival surface, in consideration of the buccolingual width of the alveolar bone in each experiment. Full insertion was confirmed for all miniscrews by checking the bone contact of the final screw thread with a dental explorer. For all miniscrews, immediately after placement, an orthodontic force of 200 to 250 g was applied with a nickel-titanium coil spring (GAC Sentalloy medium and high closed-coil springs, codes 10-000-01 and 10-000-02; Dentsply GAC International, Bohemia, NY) engaged reciprocally. To minimize the difference in the force applied in accordance with the miniscrew placement position, 2 types of nickel-titanium coil spring were used ( Fig 1 ). After the first set of miniscrews was inserted, loading was delivered for 12 weeks. Nine weeks after inserting the first set, the second set of miniscrews was inserted, and loading was delivered for 3 weeks. Twelve weeks after the initial operation, all experimental animals were killed.

| Location | Beagles 4, 8, 12 | Beagles 3, 7, 9 | Beagles 1, 5, 10 | Beagles 2, 6, 11 | ||||

|---|---|---|---|---|---|---|---|---|

| Left mandible: Removal torque | Right mandible: Histology | Left mandible: Histology | Right mandible: Removal torque | Left mandible: Removal torque | Right mandible: Histology | Left mandible: Histology | Right mandible: Removal torque | |

| PM2 | AO-3w | AO-12w | AO-3w | AO-12w | MS-3w | MS-12w | MS-3w | MS-12w |

| PM3 | MS-3w | MS-12w | MS-3w | MS-12w | AO-3w | AO-12w | AO-3w | AO-12w |

| PM4 | AO-12w | AO-3w | AO-12w | AO-3w | MS-12w | MS-3w | MS-12w | MS-3w |

| M1 | MS-12w | MS-3w | MS-12w | MS-3w | AO-12w | AO-3w | AO-12w | AO-3w |

The insertion torque was highest when the miniscrew was placed completely into the bone. The maximum insertion torque was measured during a quarter initial turn with a torque sensor (MGT50; Mark-10, Copiague, NY).

At the end of the experiment, the removal torque values of the 24 anodic oxidized and the 24 machined surface miniscrews (half after 3 weeks and half after 12 weeks of loading) were measured. After the animals were killed at 12 weeks, the remaining 48 miniscrews and the surrounding bones were dissected and fixed with 10% formalin (pH 7.4) for 1 month. After fixation, the tissues were dehydrated in serially increasing concentrations of alcohol (70%-100%) for 2 weeks. The dehydrated, fixed tissues were embedded in Technovit 8000 (Heraeus Kulzer, Hanau, Germany), cut with a diamond saw parallel to the miniscrew axis, and ground to produce serial sections (approximately 20 mm) with a grinding system (Exakt Technologies, Oklahoma City, Okla). Hematoxylin and eosin staining was performed for histomorphometric analyses.

We acquired photographs of the histologic sections with an optical microscope (Leica, Wetzlar, Germany) at 100 times magnification and saved the images as bitmap files. The bone-implant contact ratio (BIC) and the ratio of bone volume to total volume (BV/TV) were measured with Image-Pro software (version 3.0; Cybernetics Media, Rockville, Md). The borders of the miniscrews were traced, and the total bone-implant contact length at the midpoint of the vertical axis was measured on the tension and the compression sides. The BIC (%) was calculated as the length of bone in direct contact divided by the total length of the implant interface, multiplied by 100%. The BV/TV (%) was calculated as bone volume divided by total volume, multiplied by 100%.

Statistical analysis

The Shapiro-Wilk test was applied to verify the data distribution and normality. The data were normally distributed, except for the surface roughness parameters. The Mann-Whitney U test was used to identify significant differences in the surface roughness parameters between the anodic oxidized miniscrews and the machined surface miniscrews. Two-way analysis of variance (ANOVA) was used to compare the mean insertion torque, removal torque value, and BIC and BV/TV ratios according to the groups (anodic oxidized and machined surface miniscrews) and the experimental periods (3 and 12 weeks). P values less than 0.05 were regarded as statistically significant. All statistical analyses were performed with SPSS software for Windows (version 21.0; IBM Korea, Seoul, Korea).

Results

The qualitative scanning electron and atomic force microscopy analyses ( Fig 2 ) and surface roughness measurements showed different surface topographies of the 2 types of miniscrews. The surface of a machined surface miniscrew had lines produced by the mechanical machining process and a relatively smooth surface. When an anodic oxidized miniscrew was scanned at 1000 times magnification, its surface was composed of uniformly numerous nanotubular and open pores. The average surface roughness of the machined surface was 23.5 nm, and the average surface roughness of the anodic oxidized surface was 133.7 nm ( Table II ).

| Screw type | Sa (95% CI) | Sq (95% CI) | Sv (95% CI) |

|---|---|---|---|

| AO | 133.7 (104.7-162.6) | 162.6 (127.1-198.1) | 830.9 (645.9-1015.9) |

| MS | 23.5 (18.8-28.2) | 28.6 (23.0-34.1) | 147.8 (115.5-180.2) |

| Sig | * | * | * |

Both miniscrew types had 100% overall success rates (96 of 96). Miniscrew failure was defined as movement greater than 1 mm when gently luxated with forceps. The mean insertion torque values of each screw type were similar in the 3-week and 12-week loading periods ( Table III ). There was no significant difference in the removal torque values between the anodic oxidized and the machined surface miniscrews at 12 weeks: 4.1 ± 1.7 and 4.0 ± 1.5 N·cm, respectively. The removal torque values in both groups declined over the loading periods, but there were no significant differences between the time points ( Table III ).

| Time (wk) | Insertion torque (N·cm) | Removal torque (N·cm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| AO | MS | Sig | AO | MS | Sig | |||||

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | |||

| 3 | 11.4 | 4.1 | 11.7 | 4.3 | NS | 5.1 | 2.6 | 4.3 | 1.6 | NS |

| 12 | 12.4 | 4.9 | 12.5 | 5.1 | NS | 4.1 | 1.7 | 4.0 | 1.5 | NS |

| Sig | NS | NS | NS | NS | ||||||

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses