Introduction

This study aimed to assess the effect of clinical exposure on the surface morphology, dimensions, and frictional behavior of metallic orthodontic brackets.

Methods

Ninety-five brackets, of 3 commercial brands, were retrieved from patients who had finished orthodontic treatment. As-received brackets, matched by type and brand, were used for comparisons. Surface morphology and precipitated material were analyzed by optical and scanning electron microscopy and x-ray microanalysis. Bracket dimensions were measured with a measuring microscope. Resistance to sliding on a stainless steel wire was assessed.

Results

Retrieved brackets showed surface alterations from corrosion, wear, and plastic deformation, especially in the external slot edges. Film deposition over the alloy surface was observed to a variable extent. The main elements in the film were carbon, oxygen, calcium, and phosphorus. The as-received brackets showed differences ( P <0.05) in the slot sizes among brands, and 1 brand showed a 3% increase in the retrieved brackets’ slots. The frictional behavior differed among brands. Retrieved brackets of 2 brands showed 10% to 20% increases in resistance to sliding.

Conclusions

Metallic brackets undergo significant degradation during orthodontic treatment, possibly with increased friction. At present, it is difficult to predict the impact of these changes on the clinical performance of orthodontic components.

The degradation of metallic materials placed in patients has long been a concern of biomaterials science. Laboratory experiments that simulate in-vivo degradation of metal implants have made it possible to estimate the effect of specific parameters but lack the consistency required to represent the complexity of the oral environment. Variations in temperature and pH caused by diet, decomposition of foods and cell debris, and oral florae and their by-products are important factors to consider when evaluating the clinical behavior of dental materials and comparing them with other biomaterials. In particular, orthodontic accessories are under masticatory forces and multi-axial loads from the activation of the wire in the bracket slot.

In-vivo aged orthodontic components show signs of degradation such as morphologic changes and surface alterations from corrosion, wear, and formation of integuments. Concerns regarding the clinical impact of these alterations include (1) elements released into the oral environment and their implications on biocompatibility, and (2) impairment of the performance of the orthodontic appliance.

Orthodontic metallic materials are usually composed of alloys including several base metals such as nickel, chromium, cobalt, iron, molybdenum, and titanium. Concerning biocompatibility, nickel stands out among the other elements. Carcinogenic, mutagenic, and cytotoxic properties have been attributed to it, although no local or systemic clinical condition is clearly related to the forms of nickel used in dentistry. The lone exception is hypersensitivity reactions. Nickel might also elicit periodontal reactions such as gingival hyperplasia in orthodontic patients. This condition is hardly distinguishable from microbial-induced gingival overgrowth.

Surface alterations in orthodontic devices might compromise the appliance’s esthetics, increase microbial adhesion, modify bracket-wire activations such as torque expression, cause fractures during clinical use, and influence the magnitude of friction between the bracket and the wire. Many situations in an orthodontic practice require sliding teeth through a properly contoured archwire, and friction might cause significant loss of the applied force. Many investigations have focused on the frictional behavior of as-received orthodontic materials. Nevertheless, the alterations that orthodontic brackets undergo during treatment and their impact on clinical performance, especially friction, are mostly unknown. Therefore, we aimed to evaluate the surface morphology, dimensional stability, and frictional behavior of orthodontic metallic brackets retrieved after full orthodontic treatment, compared with as-received brackets from the manufacturers.

Material and methods

The sample consisted of brackets with a slot size of 0.559 × 0.711 mm (0.022 × 0.028 in), as described by the manufacturer, retrieved from patients who had finished orthodontic treatment in the private practice of 2 experienced orthodontists (E.S.C., O.T.). The brackets were carefully debonded with a direct bond bracket remover pliers and kept in receptacles with distilled water. They were brushed with an electric brush for 10 seconds and rinsed with distilled water to remove any loosely attached integuments. They were then kept in self-sealed sterilizing packs until analysis. The following information was registered: patient identification, date of placement and date of removal of the appliance. Brackets with obvious distortions or calcifications that hindered the engagement of a 0.546 × 0.711-mm (0.0215 × 0.028 in) cross-sectional wire were discarded.

A total of 95 brackets of different types (for premolars, canines, and incisors from both arches) were selected. The sample comprised 3 brands: 32 Mini Standard Edgewise stainless steel brackets (American Orthodontics, Sheboygan, Wis), 34 Kirium Edgewise stainless steel brackets (3M Abzil, Sumaré, Brazil), and 29 NuEdge preadjusted Roth prescription brackets (TP Orthodontics, LaPorte, Ind) made of copper-chromium alloy. The brackets were retrieved from 7 patients (mean age, 18 years 9 months), with a mean treatment time of 41 months. Stainless steel and nickel-titanium wires used in the orthodontic treatments were ligated with elastomeric and metallic ligatures.

A group of brackets as-received from the manufacturers, matched by types and brands to the sample, was used for comparisons. They were submitted to the same procedures as the retrieved specimens.

An optical reflected light microscope (BX60; Olympus Optical, Tokyo, Japan) was used to evaluate the surface morphology of the as-received and the retrieved brackets for areas of corrosion, signs of wear, plastic deformations, and adherent materials. The images were acquired in a bright field at various magnifications (50-200 times).

Fifteen retrieved brackets, equally distributed among brands, and their as-received counterparts were selected based on reflected light images for analysis in a scanning electron microscope (JSM-6360LV; Jeol, Tokyo, Japan) and an energy dispersive x-ray spectrometer. Secondary electron images and backscattered electron images were acquired at various magnifications (20-2000 times) by using a 20-kV accelerating voltage. The images allowed for assessment of the micromorphologic characteristics of the slot surfaces. Areas of interest were submitted to microanalysis for element assessment. Spectra were acquired with the same accelerating voltage at different magnifications and a 100-second acquisition time.

The slot sizes (left and right, vertical dimension) and the internal widths between the tie-wings (cervical and occlusal, horizontal dimension) of the remaining 80 retrieved brackets and their as-received counterparts were measured in a measuring microscope (MM-40; Nikon, Yokohama, Japan). Measurements were made by 1 operator using a holder with a wire of a cross-section of 0.546 × 0.711 mm (0.0215 × 0.028 in). The wire was used to position the brackets’ slots perpendicular to the microscope table. To evaluate the method error, the measurements of 12 specimens were repeated after a 1-week interval. No statistically significant difference was found between repeated measurements according to a paired-samples t test ( P = 0.69).

The sliding resistance analysis with stainless steel wires was conducted on both as-received and retrieved brackets in a universal testing machine (DL-500; EMIC, São José dos Pinhais, Brazil), with a device especially designed for this experiment ( Fig 1 ). Test specimens were obtained by bonding the brackets with a cyanoacrylate adhesive to a 4 × 15 × 50-mm acrylic plate with a holder in a standardized way. This guaranteed that the bracket slots stayed parallel to the testing machine’s vertical axis. Stainless steel wire segments (Shiny Bright, TP Orthodontics) with a cross-section of 0.4826 × 0.635 mm (0.019 × 0.025 in) and a length of 11.5 cm were used. The wires were cleaned with 70% alcohol. They were ligated in their middle portion to the brackets with 3.0-mm elastomeric ligatures (Mini Stix noncoated, TP Orthodontics) immediately before the test to standardize the ligation force. Each segment was used only once.

Test specimens were mounted in the device and assembled in the test machine. A 300 g weight was attached to the lower extremity of the wire to keep it under tension. The wire was pulled along the bracket at a rate of 5 mm per minute for 1 minute. The force levels were registered by a 10 kgf load cell. The sliding resistance was calculated by averaging the forces registered between the first and fifth millimeters of displacement, disregarding the initial static friction. Since the retrieved brackets were of different types, even for the same brand, it was of no use to consider the mean sliding resistance for each brand, but only the differences between retrieved and as-received brackets. For means of comparison among the different brands, the percentage difference in the sliding resistance between retrieved and as-received brackets was calculated with the following equation: DifSR(%) = [(SRretrieved − SRas-received)/SRas-received] × 100, where DifSR is the percentage difference in sliding resistance, and SR is sliding resistance.

Statistical analysis

Kolmogorov-Smirnov and Levene tests were used to evaluate the normality of data distribution and the homogeneity of variance, respectively. Only the tie-wings’ widths and the percentage differences in the sliding resistance variables had nonnormal distributions. Only the as-received brackets’ sliding resistance had a homogeneous variance. The effect of usage on the tie-wings’ widths was investigated with the Mann-Whitney test. Slot dimensions were compared among brands and usage conditions (as-received or retrieved) with analysis of variance (ANOVA) and the Games-Howell post-hoc test. The Kruskall-Wallis multiple comparisons test was used to evaluate differences among brands and patients in the percentage difference in the sliding resistance. A paired-samples t test was used to investigate the effect of usage on sliding resistance for each brand in a 2-tailed model. The level of significance for all tests was set at α = 0.05.

Results

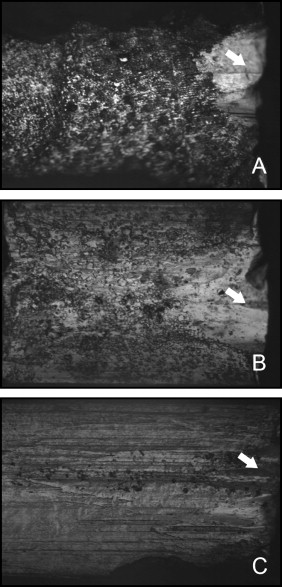

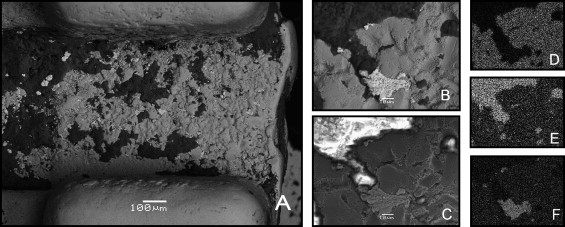

Surface modifications with signs of corrosion, plastic deformation, and wear were seen in the retrieved brackets ( Fig 2 ) when compared with the as-received brackets during optical microscopic evaluation. Wear and deformation were especially seen on the external edges of the slot bottom surface. The retrieved specimens had film deposition and islands of aggregated materials to a variable extent. The variability occurred even with brackets removed from the same patient, with no individual pattern in the amount of integument formed. Mini Standard Edgewise retrieved brackets’ slots varied in areas with pits and film deposition or areas with extensive signs of wear and deformation. This last pattern was more frequent in retrieved Kirium brackets. NuEdge brackets had a rough surface, with pits and crevices in a parallel arrangement, in both as-received and retrieved specimens. These originally roughened surfaces, a coating applied by the manufacturer, and the presence of integuments made it difficult to evaluate specific usage-related alterations in NuEdge brackets.

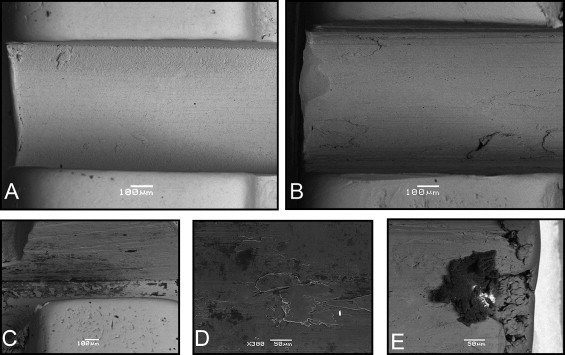

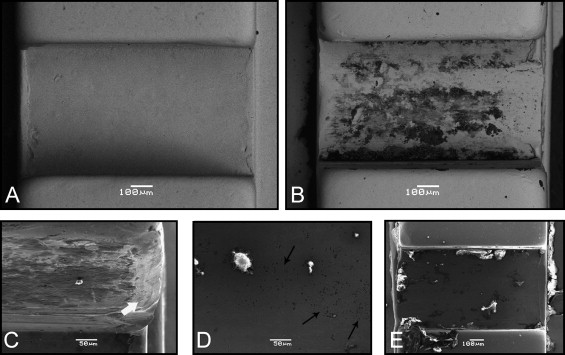

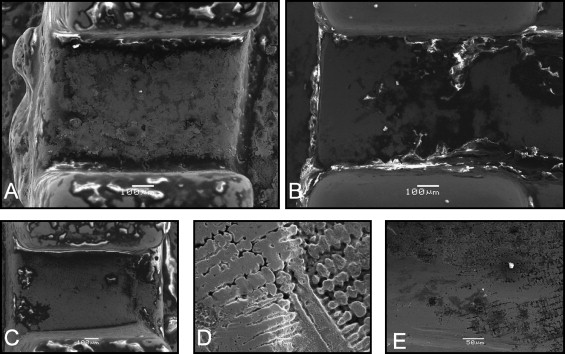

The same morphologic patterns were seen in greater detail in the scanning electron microscope images ( Figs 3-5 ). The precipitated film exhibited a dark phase in the backscattered electron images, contrasting with the bright phase of the brackets’ alloy. This finding suggested the presence of elements with a low atomic number in the film. Carbon, oxygen, calcium, and phosphorus were the main elements detected in the film by energy dispersive x-ray spectrometry microanalysis. However, nitrogen, sulfur, sodium, potassium, and aluminum were eventually found. In some areas, the precipitates masked the topographic features of the underlying alloy surface ( Fig 6 ). Greater magnifications showed details of the arrangement of pits and crevices in the NuEdge specimens ( Fig 5 , D and E ). The coating applied by the manufacturer in the as-received NuEdge brackets was seen in backscattered electron images as a dark-phased, noncontinuous pellicle. The same distribution was not seen in the retrieved specimens, in which the integuments were limited to slots and gaps. The original coating was visually indistinguishable from the biofilm formed during oral exposure. Some materials of atypical composition were found in retrieved brackets, including a 150-μm precipitate containing silica, aluminum, barium, iron, carbon, and oxygen ( Fig 3 , E ). Also included were silver and silica incrustations that had a brighter phase than the cobalt-chromium alloy ( Fig 6 ).

A comparison between as-received and retrieved brackets found no significant difference ( P >0.05) in the tie-wings’ internal widths ( Table I ). Table II presents the slot dimensions according to usage and brands. NuEdge brackets had significantly greater slot dimensions than the other brands ( P <0.05). Differences between retrieved and as-received brackets were seen only for the right slot of the Kirium brackets ( P <0.05).