CHAPTER 22 Repairs and Additions to Removable Partial Dentures

Broken Clasp Arms

The following are several reasons for breakage of clasp arms:

1. Breakage may result from repeated flexure into and out of too severe an undercut. If the periodontal support is greater than the fatigue limit of the clasp arm, failure of the metal occurs first. Otherwise the abutment tooth is loosened and eventually is lost because of the persistent strain that is placed on it. Locating clasp arms only where an acceptable minimum of retention exists, as determined by an accurate survey of the master cast, can prevent this type of breakage.

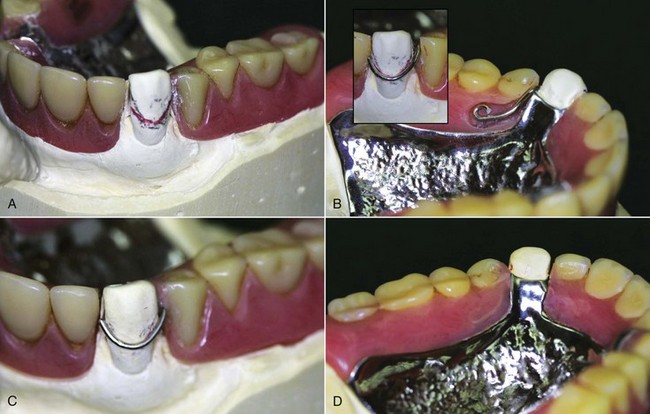

2. Breakage may occur as a result of structural failure of the clasp arm itself. A cast clasp arm that is not properly formed or is subject to careless finishing and polishing eventually will break at its weakest point. This can be prevented by providing the appropriate taper to flexible retentive clasp arms and uniform bulk to all rigid nonretentive clasp arms. Wrought-wire clasp arms may eventually fail because of repeated flexure at the region where it exits from the resin base (Figure 22-1), or at a point at which a nick or constriction occurred as a result of careless use of contouring pliers. They also may break at the point of origin from the casting as a result of excessive manipulation during initial adaptation to the tooth or subsequent readaptation. Clasp breakage can best be prevented by cautioning the patient against removing the removable partial denture by sliding the clasp arm away from the tooth with the fingernails. A wrought-wire clasp arm can normally be adjusted several times over a period of years without failure. It is only when the number of adjustments is excessive that breakage is likely to occur. Wrought-wire clasp arms also may break at the point of origin because of recrystallization of the metal. This can be prevented by proper selection of wrought wire, avoidance of burnout temperatures exceeding 1300°F, and avoidance of excessive casting temperatures when a cast-to method is used. When wrought wire is attached to the framework by soldering, the soldering technique must avoid recrystallization of the wire. For this reason, it is best that soldering be done electrically to prevent the wrought wire from overheating. A low-fusing (1420°F to 1500°F), triple-thick, color-matching gold solder should be used rather than a solder that possesses a higher fusing temperature.

3. Breakage may occur because of careless handling by the patient. Any clasp arm will become distorted or will break if subjected to excessive abuse by the patient. The most common cause of failure of a cast clasp arm is distortion caused by accidental dropping of the removable partial denture. A broken retentive clasp arm, regardless of its type, may be replaced with a wrought-wire retentive arm embedded in a resin base (see Figure 22-1C and D) or attached to a metal base by electric soldering. Often this avoids the necessity of fabricating an entirely new clasp arm.

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses