19

The Role of Biomedical Engineers in the Design and Manufacture of Customized Orthodontic Appliances

Summary

Currently, there are numerous opportunities for biomedical engineers to interact with orthodontists to produce customized appliances, such as shape-memory polymer wires, self-healing materials, smart brackets with force-moment sensors, biomimetic adhesives, and self-cleaning materials. These exciting new applications are discussed in the second part of this chapter. The first part summarizes extensive past work performed by investigators with a biomedical engineering orientation, and also reviews important complementary publications, to gain insight into orthodontic appliances and develop new appliances.

Introduction

The broad scope of modern biomedical engineering (Box 19.1) is based on integration of engineering principles with biological sciences to develop devices, materials, and procedures that improve the health of people. To seek past examples of collaboration between biomedical engineers and orthodontists, a search of the biomedical literature using PubMed (www.ncbi.nlm.nih.gov/pubmed/), and the search terms ‘orthodontic appliances’ and ‘biomedical engineering’, was performed and revealed 42 publications since 1971 in the areas of: archwire-bracket friction; archwires; force measurements, including degradation of force-delivery modules; orthodontic appliances, including use of finite element analysis; and miscellaneous subjects, such as Streptococcus mutans and PCR (polymerase chain reaction), allergic reactions to materials, and mechanical behavior of the periodontal ligament. Examination of these publications revealed that authors typically had biomedical engineering and other engineering affiliations, which accounted for the indexing of the articles by PubMed, although there was generally no specific mention in the articles about the applications of biomedical engineering principles. While these publications are only a small subset of the many published articles in the aforementioned areas, they nonetheless provide excellent examples of how biomedical engineering principles have been applied in the past to orthodontic appliances. The first part of this chapter will summarize important past research activities involving collaborations between biomedical engineers and orthodontists, and the second part will describe current areas of research and potential future applications where there are highly promising new opportunities for such collaboration.

Box 19.1 Examples of areas of modern biomedical engineering

- Biomaterials (hard tissues, soft tissues, and implants for in vivo applications)

- Biomechanics (e.g. implant and tissue mechanics, use of sensors, gait analyses, and analyses for trauma and stroke patients)

- Conventional biomedical devices (e.g. heart pacemakers and hemodialysis catheters)

- Microfabrication and nanofabrication of new devices (e.g. laboratory on a chip concept)

- Biomedical imaging (scanning electron microscopy, atomic force microscopy, magnetic resonance, and ultrasound)

- Cell and tissue engineering (growth of replacement body parts for transplantation)

Past Research Activities

Archwire-Bracket Friction

The principal past research to understand the scientific basis of archwire-bracket friction and its applications to clinical orthodontic treatment was performed by the late Professor Robert Kusy and his group of graduate students. Professor Kusy was jointly appointed to the Department of Biomedical Engineering of the School of Medicine and in the School of Dentistry at the University of North Carolina at Chapel Hill.

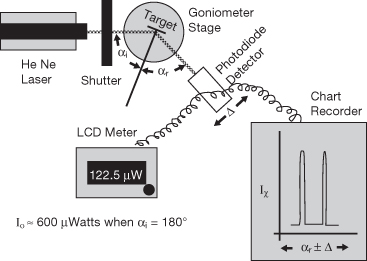

Professor Kusy’s initial study (Kusy et al., 1988) investigated the effects of surface roughness measured by laser specular reflectance (Figure 19.1) on the coefficients of static and dynamic friction in the dry state for model orthodontic systems that employed metallic archwires, lapped stainless steel, and as-received polycrystalline alumina surfaces to simulate brackets (Kusy and Whitley, 1990a). All-stainless steel couples of archwire and contacting surface had lower kinetic coefficients of friction than stainless steel-alumina couples, and beta-titanium had the highest coefficient of friction among archwires, although nickel-titanium archwires had the roughest surfaces. Scanning electron microscope (SEM) observations using energy-dispersive X-ray analyses revealed adhesion of beta-titanium archwires to stainless steel flat surfaces and abrasion of beta-titanium archwires by flat alumina surfaces that were microscopically rough due to the sharp facets of the fine grains of the material.

Figure 19.1 Schematic measurement of archwire surface roughness using laser reflectance spectroscopy.

(From Kusy et al. [2004]. Reprinted with permission from Elsevier.)

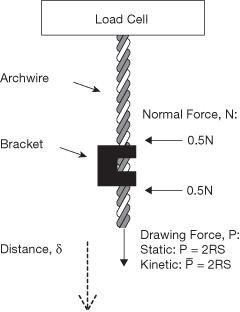

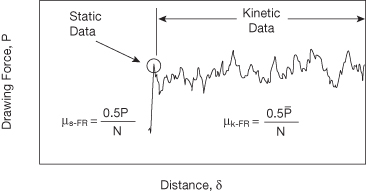

These pioneering studies with model systems were followed by an extensive series of investigations that evolved as new archwire and bracket products were introduced. Dry state friction was measured for archwires in stainless steel and polycrystalline alumina bracket slots by Kusy and Whitley (1990b). The resistance to sliding of self-ligating brackets and conventional stainless steel twin brackets for second-order angulation in the dry and wet (saliva) states was studied by Thorstenson and Kusy (2001), followed by evaluation of sliding resistance of stainless steel archwires in self-ligating brackets having passive slides and active clips (Thorstenson and Kusy, 2002a). Thorstenson and Kusy (2002b) then examined four designs of self-ligating brackets coupled with four different nickel-titanium archwires varying in size and nickel-titanium phase (Brantley, 2001). In subsequent studies, Thorstenson and Kusy (2003a) first compared the resistance to sliding for polycrystalline alumina brackets and polycarbonate brackets, with and without stainless steel inserts with control stainless steel brackets with stainless steel archwires, and then investigated (Thorstenson and Kusy, 2003b, 2004) the resistance to sliding for stainless steel archwires coupled to conventional stainless steel brackets and new bracket designs. Figures 19.2 and 19.3 (Rucker and Kusy, 2002a) illustrate the principles, schematic apparatus, and typical results for friction measurements. This study compared the resistance to sliding, in the dry and wet (saliva) conditions, of multistrand stainless steel, single-strand stainless steel and nickel-titanium archwires. The coefficients of binding were not affected by saliva but were proportional to wire stiffness, and differences in the kinetic coefficients of friction for stainless steel and nickel-titanium archwires became unimportant shortly after binding occurred.

Figure 19.2 Principles for measurement of archwire-bracket friction, showing normal force (N) applied to multistrand archwire, drawing force (P), distance of movement (δ), and relationships of static and kinetic force to resistance to sliding (RS).

(From Rucker and Kusy [2002a]. Reprinted with permission from Elsevier.)

Figure 19.3 Schematic illustration of drawing force–distance data, showing determination of static and kinetic coefficients of friction (μs-FR and μk-FR).

(From Rucker and Kusy [2002a]. Reprinted with permission from Elsevier.)

In the final two studies of archwire-bracket friction from the Kusy laboratory, a more clinically oriented approach was employed to compare four conventional and four self-ligating brackets. Standardized archwires were drawn through quadrants of typodont models in dry and wet (saliva) states, and the drawing forces were measured for friction evaluation (Henao and Kusy, 2004). A small archwire simulated the earlier treatment stage, and two larger archwires simulated later stages; typodonts had quadrants with progressively increasing malocclusions. In their following study (Henao and Kusy, 2005) the same methodology was used to seek the optimal archwire-bracket system, using archwires and bracket designs from four manufacturers.

The foregoing laboratory studies by the Kusy research group has provided considerable fundamental understanding about the resistance to sliding for commercial archwires in commercial conventional and self-ligating brackets, along with the role of the critical angle for binding, the consequences of using inserts in brackets, the results from novel bracket designs, and use of different archwire materials and designs. Such information in principle provides the orthodontist with the ability to select the optimum archwires and brackets for a scientific approach to different patient treatment cases.

There is a prolific literature in this area in which biomedical engineers were not generally involved, with over 300 articles cited by PubMed, beginning with Andreasen and colleagues in 1969. The articles by the Kusy research group were selected to illustrate past interactions between biomedical engineers and orthodontists in the investigation of archwire-bracket friction.

In a recent review article, Burrow (2009) comments that clinical studies indicate a minimal role for archwire-bracket sliding friction in bodily tooth movement, which instead involves successive steps of archwire binding by the bracket and its release. He also notes that clinical studies to date do not indicate that treatment time is reduced with self-ligating brackets because of lower friction. This important article stimulated several responses and replies in the Readers’ Forum of the American Journal of Orthodontics and Dentofacial Orthopedics (July and December 2009). The reader is also directed to a classic article by Tidy (1989) on the in vitro measurement of frictional forces in fixed orthodontic appliances and a later article by Loftus et al. (1999) presenting an in vitro dentoalveolar model for measurement of frictional forces. Reznikov et al. (2010) have recently described a new system for measuring friction in vitro in a study that investigated stainless steel archwires and self-ligating brackets. These authors found that under certain clinical situations a firm passive bracket clip can adversely affect friction. However, none of these four pieces of research involved collaboration between orthodontists and biomedical engineers. New collaborations are needed for further progress in fundamental understanding of the sliding of the different types of archwires in the wide variety of commercially available brackets and how clinical treatment is affected by the complex archwire-bracket interactions that occur.

Fabrication and Characterization of Nonmetallic Archwires

McKamey and Kusy (1999) created a polymer-polymer composite wire, designed for use as a ligature, by encasing ultra-high molecular weight polyethylene fibers in poly (n-butyl methacrylate) formulated from a polysol containing benzoin ethyl ether. Subsequently, Zufall and Kusy (2000a,b) created poly(chloro-p-xylylene)-coated glass fiber-reinforced composite archwires made by photo-pultrusion from S2-glass and a polymer formed from bisphenol-A diglycidyl methacrylate (Bis-GMA) and triethylene glycol dimethacrylate (TEGDMA), with benzoin ethyl ether as ultraviolet-light photoinitiator. Strength and force decay were measured for the polymer-polymer composite archwires, and the frictional and viscoelastic behavior of the fiber-reinforced polymer archwires was investigated extensively. Mathematical models were developed that described the in vitro behavior of the polymeric wires. Nonetheless, while laboratory results indicated that both polymeric wires would be suitable for their intended clinical applications, these wires were never introduced as commercial products, presumably because of the costs associated with developing the manufacturing techniques.

Besides the aforementioned articles published by the Kusy research group that involved collaborations between biomedical engineers and orthodontists, other similar collaborative research on nonmetallic archwires has also been reported. Based on collaboration between the orthodontic faculty at the Hokkaido University School of Dentistry and an engineering faculty member at the Chiba Institute of Technology in Japan, Imai et al. (1998) reported a study of fiber-reinforced polymeric archwires containing CaO–P2O5–SiO2–Al2O3 glass fibers that were longitudinally oriented in a polymethyl methacrylate matrix using a hot-drawing method. The glass fiber surfaces of these wires were treated by a silane coupling agent to improve bonding with the polymer matrix. More recent collaboration between engineering mechanics, bioengineering, and orthodontics faculty at Tongji University in China and the National University of Singapore resulted in an article by Huang et al. (2003) on a tube-shrinkage technique that was used to fabricate longitudinally oriented glass fibers (E-glass) in an epoxy resin matrix. These authors noted that this novel technique did not have the problem of fiber damage or the limitation of a straight cylindrical geometry associated with the pultrusion (drawing) technique that had been previously used to fabricate unidirectional fiber-oriented composite archwires. Their work also led to a US Provisional Patent (60/436,466; December 27, 2002): ‘Fiber-reinforced composite product with flexible longitudinal geometry’.

It is important to acknowledge the extensive past research by Goldberg and Burstone, which also represented collaboration between a bioengineer and an orthodontist, on the development of fiber composites for a variety of dental applications, including orthodontic archwires. The publications from their past work can be easily found on PubMed, and at the time of going to press, an exciting new publication (Burstone et al., 2011) on polyphenylene polymer archwires appeared in the American Journal of Orthodontics and Dentofacial Orthopedics.

Fundamental Studies of Metallic Archwires

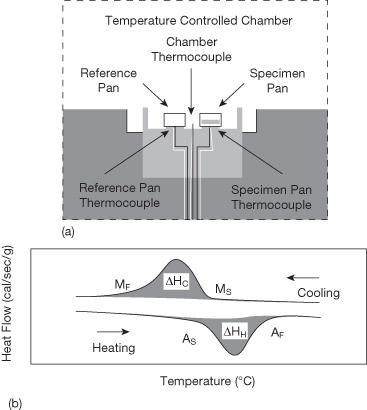

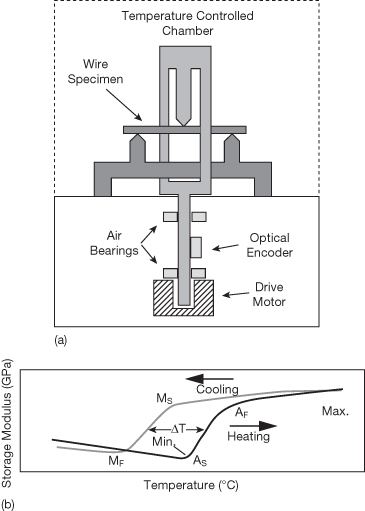

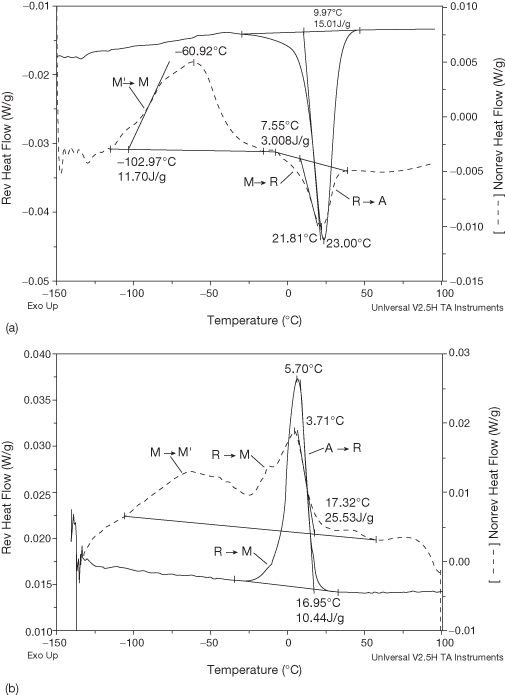

Two important laboratory techniques that have been employed to investigate the mechanical properties and structures of nickel-titanium orthodontic archwires, where these relationships have enormous clinical importance (Brantley, 2001), are differential scanning calorimetry (DSC) (Lee et al., 1988; Khier et al., 1991) and dynamic mechanical analysis (DMA) (Kusy and Wilson, 1990; Kusy and Whitley, 2007). Schematic illustrations of the experimental set-ups for conventional DSC and DMA, along with schematic plots of the results from both techniques, are provided in Figures 19.4 and 19.5.

Figure 19.4 (a) Schematic experimental set-up for conventional differential scanning calorimetry (DSC). (b) Schematic DSC plot for nickel-titanium orthodontic wire, showing enthalpy changes for heating (ΔHH) and cooling (ΔHC), start (As) and finish (AF) temperatures for transformation from martensite to austenite during heating, and start (MS) and finish (MF) temperatures for transformation from austenite to martensite on cooling.

(From Kusy and Whitley [2007]. Reprinted with permission from Elsevier.)

Figure 19.5 (a) Schematic experimental set-up for dynamic mechanical analysis (DMA). (b) Schematic DMA plot of changes in storage modulus for nickel-titanium orthodontic wire, showing effects of transformation from martensite to austenite for heating and transformation from austenite to martensite for cooling, start and finish temperatures for both transformations, and temperature difference (hysteresis) between heating and cooling curves in transformation temperature range.

(From Kusy and Whitley (2007). Reprinted with permission from Elsevier.)

Conventional DSC provides information about temperatures for transformations between higher-temperature austenite and lower-temperature martensite phases, along with enthalpy changes (ΔH), and clearly differentiates among wires having true shape memory in vivo and the superelastic and nonsuperelastic wires (Khier et al., 1991). Temperature-modulated DSC (Brantley et al., 2003), where a small sinusoidal thermal oscillation is superimposed on the linear heating/cooling ramp of conventional DSC, provides additional insight into transformations of nickel-titanium wires (Figure 19.6), including occurrence of the intermediate R-phase and a low-temperature transformation within martensite, which was found to be twinning by transmission electron microscopy (Brantley et al., 2008).

Figure 19.6 Temperature-modulated DSC plots for (a) heating and (b) cooling of 35°C Copper Ni-Ti. Transformations involving austenite (A), martensite (M) and R-phase (R) are designated by arrows. The R-phase transformation in many orthodontic wires is not detected by conventional DSC analysis.

(From Brantley et al. [2003]. Reprinted with permission from Elsevier.)

With dynamic mechanical analysis, test specimens are subjected to an oscillating stress. Values are obtained for: (1) storage modulus corresponding to the strain component in-phase with stress (analogous to Young’s modulus for tension or shear modulus for that loading mode), (2) loss modulus for the strain component 90° out-of-phase with stress, and (3) tangent delta (ratio of loss modulus and storage modulus), which indicates the level of viscoelastic (nonlinear elastic) behavior. While the dynamic mechanical properties of stainless steel and beta-titanium archwires did not vary over the DMA temperature range from −30°C to 80°C, differences in transformations observed by Kusy and Whitley (2007) for nonsuperelastic and superelastic archwires could have clinical significance. Values of transformation temperatures determined by DSC and DMA differ because the test specimens for the former technique are not subjected to stress during analysis, in contrast to the sinusoidal stress for DMA.

The mechanical properties of stiffness (elastic modulus), strength (force or stress for elastic limit, or maximum moment for elastic deformation) and range (extent of elastic deformation) are fundamental for the clinical performance of archwires. The relationship between these elastic properties and their measurement (which can be performed in tension, bending, or torsion) are discussed by Brantley et al. (2001), where previous research on measuring these properties by the Kusy group is also presented.

In more recent research, Rucker and Kusy (2002b) compared stiffness, strength, and range for three-strand and six-strand stainless steel wires with single-strand stainless steel and nickel-titanium leveling wires, as well as measuring the properties of wire segments in tension. They concluded that fabrication of multistrand stainless steel wires using alloys with enhanced tensile yield strength would allow these wires to compete better against conventional nickel-titanium wires. Rucker and Kusy (2002c) used bending and tension tests to investigate the properties of noncoated single-strand stainless steel and superelastic nickel-titanium wires, nylon-coated single-strand and multistrand stainless steel wires, and noncoated multistrand stainless steel and nickel-titanium wires. An important conclusion of this research was that few superelastic nickel-titanium wires are activated sufficiently in vivo to exhibit superelastic behavior, i.e. the superelastic plateau for unloading (Brantley, 2001).

In another important study, Kusy et al. (2004) investigated the composition, morphology, surface roughness, and sliding mechanics of six titanium-based archwires using an SEM with X-ray energy-dispersive analyses, laser specular reflectance, and a friction testing machine. Five wires were beta-titanium alloys with compositions similar to the original TMA (Ormco) product, and the sixth was an alpha-beta alloy containing 6 wt. % Al and 3 wt. % V. Beta-titanium alloys are of particular clinical interest because of their biocompatibility due to the absence of nickel (Brantley, 2001). A variety of surface morphologies were observed, and specular reflectance and optical roughness measurements divided these wires into two groups. For values of angulation covering passive and active regions of sliding, coefficients of friction varied narrowly and were independent of surface roughness. Consequently, the authors suggested that from a clinical viewpoint, all six titanium-based archwire products were compa/>

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses