Dental Waxes

Chapter Objectives

On completion of this chapter, the student will be able to:

1. Identify the common components of dental waxes.

2. Identify the properties of waxes.

3. Describe the clinical/laboratory significance of each of the properties.

4. Identify the three classifications of waxes.

7. Obtain a bite registration using bite registration or utility wax.

Key Terms defined within the chapter

Wax Pattern a duplicate of the restoration carved in wax

Melting Range a range of melting points of the individual components of wax

Flow the movement of wax as it approaches the melting range

Excess Residue a wax film that remains on an object after the wax is removed

Dental waxes are used in a wide variety of clinical and laboratory dental procedures. Clinically, they may be used to fabricate direct waxings for cast restorations, alterations and adaptations for impression trays, and wax bite registrations. In the laboratory, they may be used to box an impression before pouring a gypsum product, as baseplates for full and partial dentures, to hold components together before articulation, and to provide indirect patterns for casting.

The dental assistant and hygienist typically will not fabricate the actual direct or indirect wax pattern for a dental casting, but they do need an appreciation for the many steps in the procedure known as the lost wax technique (described later in this chapter). The assistant and the hygienist, who is assisting or acting as the operator, will frequently manipulate waxes in taking alginate impressions, pouring the impression, and taking a wax bite registration for articulation of the models.

Composition and Properties

Dental waxes are composed of a mixture of components from natural and synthetic sources. Natural waxes are produced from plants, used in carnauba wax; insects, used in beeswax; and minerals, used in paraffin wax. These natural waxes contribute properties to the wax but are rarely used in their pure form. They are combined or mixed with synthetic waxes, gums, fats, oils, resins, and coloring agents. Each component is added to attain the physical properties desirable for the wax application. Use of the wax will determine properties that are desirable for its application.

Properties that contribute to the melting range, flow, thermal expansion, and excess residue are important considerations for dental wax. The operator must regard these properties when making a wax selection, as well as during manipulation of the wax.

Melting Range

Dental waxes have a melting range, a range of temperatures at which each component of the wax will start to soften and then flow. The components with lower melting points will soften first; then, as the temperature is increased, more components will soften and the wax will eventually flow. Because wax is unstable, the operator must be careful to prevent its distortion. Controlling the temperature of the wax allows operator control of the viscosity of the wax. In many cases, the operator does not want the wax to flow but only soften. A flame source is needed if a flowable state is desired.

Flow

Flow is the movement of wax as molecules slip over each other. As the temperature of the wax increases, the viscosity of the wax decreases until the wax becomes a liquid. Control of the flow and the melting range, which produce a flowable material, is important in manipulating the wax. If a wax were capable of flowing at room temperature, it would be very difficult to control. However, even at mouth temperature, there is a point at which flow is undesirable. If you were using a wax for a wax bite registration, you would not want it to flow at mouth temperature, causing distortion of the wax. It is important that the wax does not require temperatures much greater than mouth temperature to soften, or it would be uncomfortable when placed in the mouth of the patient. A melting range that is only slightly higher than mouth temperature is desirable for this wax application. For laboratory purposes, waxes may have a much higher melting range. However, even for laboratory purposes, high melting ranges may be undesirable. If you want to use a wax in the boxing of an impression, for example, it is much more desirable to mold the wax using the heat of your hands or warm water, rather than having to use a flame.

Excess Residue

It is important that all of the wax is removed from the object it is melted onto. If excess residue remains after the wax is removed, this may result in inaccuracies in the object being produced. This is especially important in the lost wax technique when the wax pattern is melted out of the investment mold.

Dimensional Change

Waxes expand when heated and contract when cooled; the thermal expansion and contraction of waxes is greater than that of any other dental material. This property is especially important for pattern waxes. If a wax is heated too far above the melting range or is heated unevenly, expansion above acceptable standards will result. Manufacturers provide temperature and handling guidelines for pattern waxes to prevent inaccuracies in the final casting. In addition, if waxes are allowed to stand, dimensional changes occur from the release of residual stress. Wax patterns should be invested within 30 minutes of carving (see Chapter 15 for more on investments).

Classification of Waxes

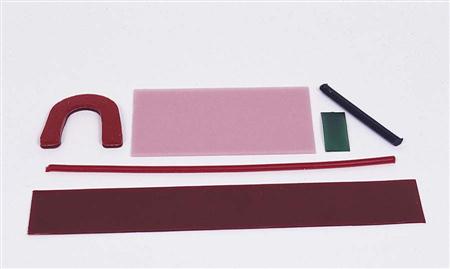

Waxes are grouped into three classifications: pattern waxes, processing waxes, and impression waxes. Manufacturers produce these waxes in several forms. Sticks, sheets, blocks, and tins are used. Waxes have unique coloring to distinguish them in use (Figure 18-1).

Pattern Waxes

Pattern waxes are used in the construction of metal castings and bases for dentures.

Inlay Waxes

Inlay waxes are used to produce patterns for metal casting through the lost wax techn/>

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses