Introduction

Coated archwires have been introduced to improve esthetics during orthodontic treatment. Our aim was to investigate the mechanical properties of coated superelastic archwires compared with conventional superelastic archwires with conventional and self-ligating brackets.

Methods

Four types of orthodontic archwires were investigated, 2 superelastic nickel-titanium and 2 coated Ultraesthetic archwires in 0.016-in and 0.018 × 0.025-in dimensions (all from G&H Wire, Greenwood, Ind). To achieve the same nominal size, the coated archwire is constructed from a smaller archwire that, when coated, reaches the nominal dimensions stated for the archwire. Conventional edgewise Orthos and Damon 2 self-ligating brackets (both from Ormco, Orange, Calif) were used with each wire. All specimens were tested in a universal testing machine in a 3-point bending test at a speed of 1 mm per minute and deflected for 2 mm. Loading and unloading forces were recorded and load-deflection curves plotted.

Results

Coated superelastic wires produced statistically significantly lower forces in loading and unloading when compared with the superelastic nickel-titanium wires at most archwire deflections ( P <0.01). For nickel-titanium wires, loading values ranged from 189 to 1202 g, whereas the respective values for coated wires were 124 to 772 g. For all wires, an increase in size resulted in an increase in force. Interactions between wire type (coated or uncoated) and bracket type were observed.

Conclusions

Ultraesthetic coated archwires produced lower force values in loading and unloading compared with uncoated wires of same nominal size. The Damon 2 self-ligating bracket system produced lower force values in loading and unloading. The lowest forces were generated by the combination of Ultraesthetic coated archwires and Damon 2 self-ligating brackets.

The demand for esthetic orthodontic appliances is increasing, and development of materials with acceptable esthetics for patients and adequate clinical performance for clinicians is needed. Esthetics of orthodontic appliances have improved significantly with the use of the latest esthetic transparent brackets made of ceramics or composites. There are 2 forms of esthetic orthodontic archwires: fiber-reinforced composite and coated metal. Fiber-reinforced wires are still experimental and not available commercially, but they look promising for the future of esthetic archwires.

Coated metallic archwires are currently the only esthetic orthodontic archwires available for clinical use. Materials used in coating are plastic resin materials such as synthetic fluorine-containing resin or epoxy resin composed mainly of polytetrafluoroethylyene to simulate tooth color. The epoxy coating is manufactured with a depository process that plates the base wire with an epoxy resin of approximately 0.002 in thick. Thus, a strong adhesion is achieved between the epoxy coating and the wire.

When the frictional behavior of plastic-coated archwires was compared with noncoated reference wires by the same manufacturer, plastic coating was found to have a significant effect in decreasing friction. In contrast, Proffit described this coat as “undurable.” Kusy found that, when coated, the colored wires are routinely damaged from forces of mastication and activity of the enzymes in the oral cavity within 3 weeks of their use in vivo. Other authors also encountered difficulties with these coated archwires, claiming that the color tends to change with time and the coating splits during usage in the mouth, exposing the underlying metal. However, despite these problems with the durability of the coating, these wires continue to be marketed and used in clinical practices, even though no studies have examined their mechanical properties.

The test used to measure the stiffness of orthodontic archwires is the 3-point bending test. It assesses load-deflection properties; this is considered the most important parameter in determining the biologic nature of tooth movement. The advantages of this test are its close simulation to clinical application, its ability to differentiate wires with superelastic properties, and the high degree of reproducibility. Nikolai and Chung reported that, with large deflections, the wire could buckle, with a decrease in unloading force. It is unclear whether this mimics the clinical situation, but it highlights the need for caution when relating mechanical property data to a clinical scenario.

The aim of this study was to investigate the mechanical properties of coated esthetic superelastic archwires in a 3-point bending test compared with conventional superelastic archwires with conventional and self-ligating brackets.

The null hypotheses were (1) there is no difference in load-deflection properties between coated and uncoated superelastic wires of the same size; and (2) there is no difference in load-deflection properties of archwires between conventional and self-ligating brackets.

Material and methods

Four types of orthodontic archwires were investigated: superelastic nickel-titanium (NiTi) and coated Ultraesthetic archwires with sizes of 0.016 in and 0.018 × 0.025 in. All wires were manufactured by G&H Wire (Greenwood, Ind). According to the manufacturer, Ultraesthetic wires are superelastic NiTi wires coated with an epoxy layer of .002 in thick. A special jig ( Fig 1 ) with 2 parallel brass rods, 5 mm in diameter, was designed and constructed. Two stainless steel Orthos edgewise central-incisor brackets (Ormco, Orange, Calif) with a slot size of 0.022 × 0.028 in were bonded onto the top of these rods with an interbracket distance of 14 mm, equivalent to the distance between the central incisor and canine bracket. The jig was fixed to the base of the universal testing machine (Zwick/Roell Z020, Zwick GmbH, Ulm, Germany). The wire specimen was attached to the brackets with elastomeric ligatures. Two self-ligating Damon 2 brackets (Ormco) were bonded at the same interbracket distance. The force was applied by using a third brass rod attached to the moving part of the testing machine heading vertically toward the middle of the interbracket distance at a crosshead speed of 1 mm per minute. The middle portion of the wire was deflected 2 mm and then unloaded at the same speed. The loading and unloading forces were registered by the load cell, and the results were analyzed with testXpert software (Zwick GmbH).

Sample size calculations for detecting 10% differences in these values suggested testing 10 archwires in each group. Two-way analysis of variance (ANOVA) was used to identify main effects (differences between bracket types and between wire types), and the effects of the interactions between different wire types and bracket types. All statistical tests were undertaken at the P <0.05 level of significance.

Results

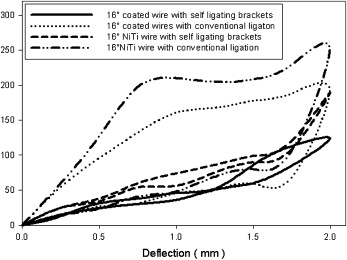

For the archwire sizes and types, means forces for 0.016-in superelastic NiTi and Ultraesthetic coated wires with conventional and self-ligating orthodontic brackets are shown in Table I , and the load-deflection curves are given in Figure 2 . Force increased as deflection increased. Coated wires resulted in lower forces, ranging from 18 to 192 g for the 0.5- and 2-mm deflections, respectively. NiTi wires ranged from 29 to 252 g for the 0.5- and 2-mm deflections, respectively.

| Loading force (g) at 2-mm deflection | Unloading force (g) at 1.5-mm deflection | Unloading force (g) at 1-mm deflection | Unloading force (g) at 0.5-mm deflection | |||||

|---|---|---|---|---|---|---|---|---|

| Wire | Ligature | Self-ligation | Ligature | Self-ligation | Ligature | Self-ligation | Ligature | Self-ligation |

| NiTi | 252 (17) | 189 (13) | 80 (14) | 89.7 (13) | 48 (11) | 56 (13) | 29 (14) | 30 (12) |

| Coated NiTi | 192 (20) | 124 (12) | 59 (12) | 60 (13) | 46 (9) | 36 (8) | 29 (10) | 18 (6) |

The results for the 0.018 × 0.025-in wires are shown in Table II and Figure 3 . Greater changes were observed for these wires. Forces in the coated wires ranged from 60 to 772 g for the 0.5- and 2-mm deflections, respectively; forces for the NiTi were 99 to 1202 g.

| Loading force (g) at 2-mm deflection | Unloading force (g) at 1.5-mm deflection | Unloading force (g) at 1-mm deflection | Unloading force (g) at 0.5-mm deflection | |||||

|---|---|---|---|---|---|---|---|---|

| Wire | Ligature | Self- ligation | Ligature | Self- ligation | Ligature | Self- ligation | Ligature | Self- ligation |

| NiTi | 1202 (33) | 979 (33) | 524 (24) | 411 (44) | 295 (26) | 228 (33) | 121 (16) | 99 (35) |

| Coated NiTi | 772 (44) | 672 (40) | 342 (24) | 260 (15) | 216 (18) | 132 (25) | 147 (32) | 60 (14) |

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses