Introduction

Our objective was to enable accurate miniscrew placement after preoperative simulation. We developed a new template for miniscrew placement and evaluated its accuracy.

Methods

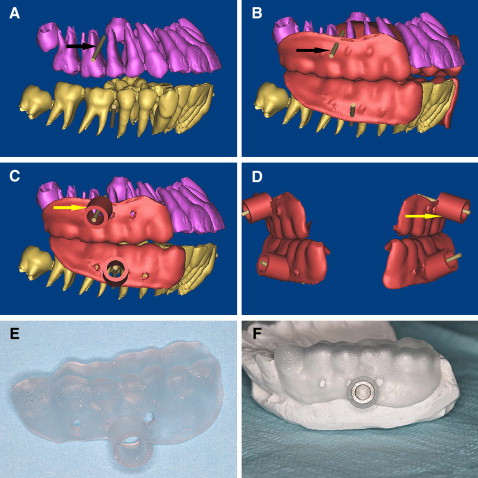

Eleven patients who had bimaxillary protrusion were scanned with computed tomography. The 3-dimensional computed tomography data were used to produce, with stereolithography apparatus, a template for accurate miniscrew placement. The interradicular space available for miniscrew placement was calculated in the 3-dimensional images. Postoperative computed tomography images were matched with preoperative images to calculate the deviations between the planned and actual placements.

Results

The distance for placement of a miniscrew between 2 roots was 4.12 mm (SD, 0.25 mm; range, 3.7-4.5 mm). The placed miniscrews showed an average angular deviation of 1.2° (SD, 0.43°; range, 0.6°-2.41°) compared with the plan, whereas the mean linear distomesial deviation was 0.42 mm (SD, 0.13 mm; range, 0.15-0.6 mm) at the tip.

Conclusions

The proposed template has high accuracy and will be especially useful for patients who require precise miniscrew placement.

Editor’s comment

The need for accurate placement of miniscrew implants for orthodontic anchorage has led to new and creative ways to use templates. In-vivo testing of a new template is the proof needed so that others can benefit from these treatment strategies.

This article reports on a miniscrew template designed with the help of 2 computer programs, MIMICS (Materialise’s interactive medical image control system) and Magics (assistant software). MIMICS is an interactive tool for the visualization and segmentation of computed tomography (CT) images and magnetic resonance images and 3-dimensional (3D) rendering of objects. In medicine, MIMICS can be used to diagnose a problem and to plan and practice the surgery to correct it. A flexible interface to rapid prototyping systems is included for building distinctive segmentation objects. Magics allows the user to further process a 3D model using stereolithography apparatus (SLA). This process uses photosensitive resins cured by a laser that traces the part’s cross-sectional geometry layer by layer. SLA produces accurate models with various materials.

Eleven patients with bimaxillary protrusion agreed to be treated with miniscrews placed with templates designed with CT data and fabricated by SLA. After extraction of the 4 first premolars, 34 miniscrews were placed to provide absolute anchorage. You will need to read the full online account for the details of the drill template and how implant placement was evaluated.

The results showed that all the deviations of the miniscrews were within the safe zone, and each was smaller than the allowed deviation. In concluding remarks, the investigators noted that the deviation was significantly smaller in the template guide group than in the control group, and the difference was statistically significant. This study showed a computer-aided design/computer-aided manufacturing (CAD/CAM) guide for orthodontic miniscrew placement that is similar to prosthetic implant guides and verified that the accuracy of the template was sufficient to control miniscrew location, allowing for safe placement.