Four relatively new technologies are now key in orthodontic specialty laboratories: digital photography, laser welding, computer-aided design/computer-aided manufacturing, and intraoral scanners. The purposes of this article are to briefly describe these technologies and to explain how they are used in the orthodontic laboratory.

Digital technology has changed orthodontic laboratory operations immensely over the last 15 years. The process has been slower in orthodontics than in other fields because of the relatively small market size of the orthodontic laboratory, with most transitions pioneered by the dental laboratories. Although technicians at some orthodontic laboratories might feel threatened by the pace of change, we are all learning that the new products and techniques improve productivity and can be great tools to express creativity. Four relatively new technologies are now key in orthodontic specialty laboratories: digital photography, laser welding, computer-aided design/computer-aided manufacturing (CAD/CAM), and intraoral scanners. The purposes of this article are to briefly describe these technologies and to explain how they can be used in the orthodontic lab.

Although they are part of our daily lives now, digital cameras made a huge impact on dentistry in 1995. Communication between the doctor’s office and the laboratory changed dramatically. Patient photos could be e-mailed back and forth to illustrate issues with models and discuss various appliance designs. Training documents could be created even before the appliance entered the production area. Processes could be documented and relayed to the technicians in a timely manner. Using photos along with PowerPoint applications (Microsoft, Redmond, Wash) helps keep employees informed of any special instructions and design changes as they progress.

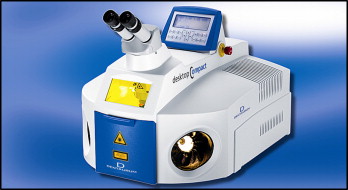

In 2002, the laser welder was introduced to the orthodontic laboratory. Although laser welding has been available for over 30 years, it was not until the mid-1990s that dental laboratories began using it for appliances. The laser welder ( Fig 1 ) uses a highly concentrated light to fuse metals. The weld is controlled by the duration that the light is applied, the amount of power supplied, and the diameter of the laser beam. Because the metals are fused, the resulting bond is better than that produced by brazing, in which the metals are wrapped together with a third alloy. With brazing, many factors contribute to the success of a bond; the most critical is the technician’s technique. A brazed joint must be clean and the proper amount of flux applied; any shortcomings and the appliance will most likely fail during treatment. With the forces that orthodontic appliances must endure, everything possible must be done to ensure that the metals are joined properly. Laser welding is ideal because the technician has only to select the task to be completed, and the preset control panel takes care of the rest. A focal point on the laser welder helps keep the technician from misfiring; the welder will not fire when parts are out of focus. Manufacturers give basic guidelines on the proper settings for laser welders. Technicians can adjust the settings somewhat to allow for their own ability and experience. For example, the power setting can be reduced for a technician whose hand moves slower through the welding zone, without damaging the parts or reducing the strength of the metals. Laser systems enable a technician to consistently produce strong joints.