CHAPTER 1 Low-friction esthetic brackets

The Clarity™ SL Self-Ligating Appliance System

Introduction

A desire for orthodontic treatment that does not adversely affect facial esthetics, both during and after treatment, is increasingly seen in the orthodontic practice. The first esthetic appliances date back to the 1970s and were manufactured in plastic.1–3

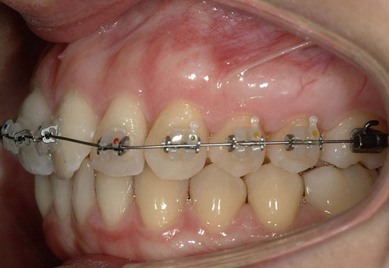

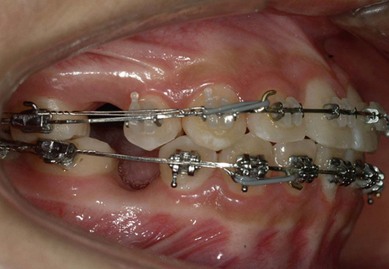

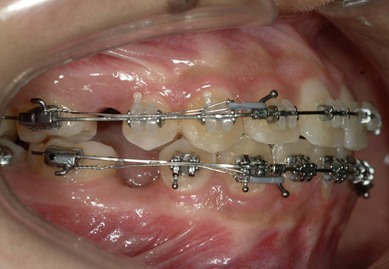

While there are several obvious advantages of esthetic appliances, there are also some disadvantages. One major issue is the change in color of the elastic modules used to hold the archwire in the bracket slot, which is caused by poor oral hygiene or the eating habits of the patient (Figs 1.1, 1.2 & 1.3). The patients who most often experience this problem are those who drink coffee, tea, red wine, etc. on a frequent basis, as well as patients who smoke. These patients have to come back to the office more often simply for new elastic modules in an effort to maintain the esthetics of their appliance.

When the SmartClip™ Self-Ligating Appliance was released in 2004, the possibility of having a Clarity-style appliance featuring the characteristics of a self-ligating appliance became apparent. However, this appliance would not only have to have the same characteristics as the metal4 self-ligating appliance, but would also have to address the needs of patients who were looking for a more esthetic smile during the treatment. In 2007, new advances in technology made it possible to manufacture the Clarity™ SL Self-Ligating Appliance. It featured the same characteristics as the conventional Clarity™ appliance, e.g. a ceramic bracket with a metal slot and a unique debonding mechanism. The Clarity™ SL Self-Ligating Appliance utilizes the same manufacturing technology as the metal self-ligating appliance, with Nitinol clips on the mesial and the distal bracket wings.

Characteristics of the appliance

The Clarity™ SL Self-Ligating bracket is composed of three parts that are manufactured separately: the ceramic bracket body, the metal slot and the Nitinol clips (Fig. 1.4). The bracket body is manufactured in ceramics and the bracket slot is produced in metal and inserted in the bracket base. The Nitinol clips are laser cut and pressed onto the mesial and the distal sides of the bracket. The clips are designed to be fatigue resistant while both engaging and removing archwires. As mentioned above, the bracket system offers the same features as the conventional appliance, enabling the use of elastic chains, metal and elastic ligatures and all the other attachments that are usually used with the conventional approach.

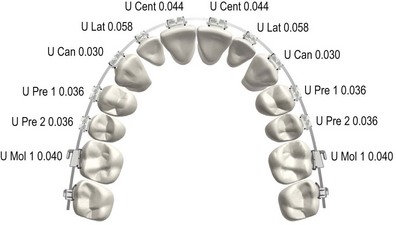

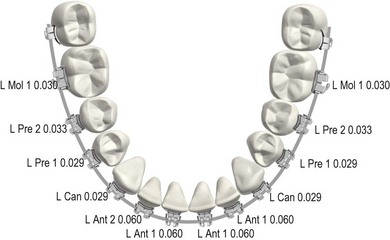

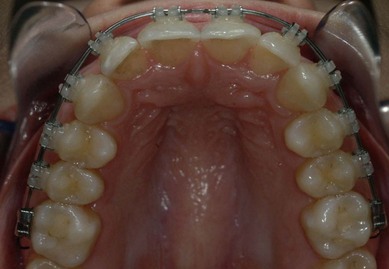

The Clarity™ SL Self-Ligating Appliance System prescription

As mentioned above, the Clarity™ SL Self-Ligating Appliance System features a bracket designed for sliding mechanics, that is when using a .019/.025 archwire in the .022/.028 bracket slot. This is usually the last archwire to be used in treatment. The basic orthodontic concepts underlying the use of the Clarity™ SL Self-Ligating Appliance System are the same as those for the SmartClip™ Self-Ligating Appliance System (Figs 1.5, 1.6 & 1.7).

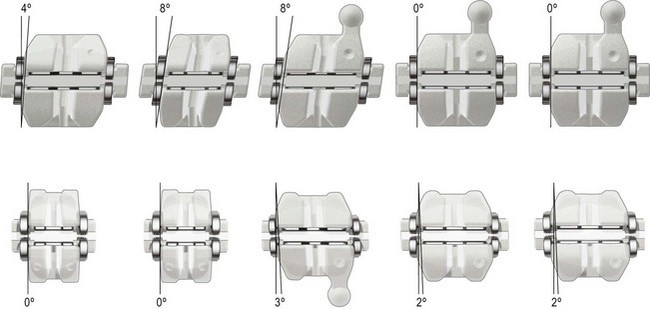

Mesiodistal angulation

The basic Clarity™ SL bracket design is the same as the conventional brackets – rhomboidal brackets with built-in angulation. The rhomboidal shape makes bracket positioning easier, along with the use of the individualized bracket positioning system4–6 (Figs 1.8, 1.9 & 1.10).

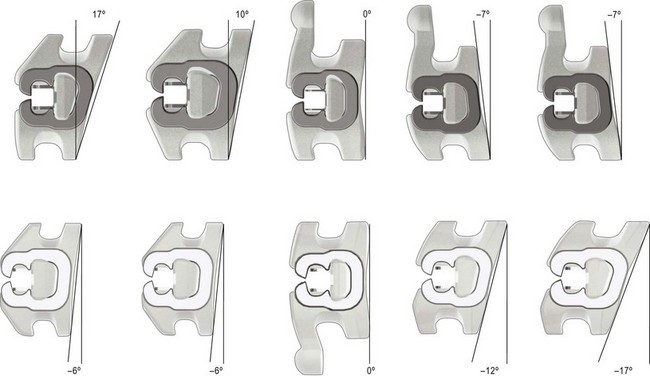

Inclination (torque)

A highly sophisticated manufacturing process allows the addition of a metal slot into the ceramic bracket body of the Clarity™ SL bracket. The reliability of an orthodontic appliance depends on the degree of expression of the torque that is built into the bracket base and the bracket slot. A metal slot imparts greater strength to the bracket and allows full torque expression. Furthermore, the metal slot facilitates good sliding of the archwire during the orthodontic treatment by reducing friction.7,8 The Clarity™ SL appliance also features built-in torque in the metal slots (Fig. 1.11).

In-out

From the horizontal aspect, the functional harmony of the orthodontically created occlusion is determined by the in-out built into the appliance, the shapes of the archwires used, and the coordination achieved between the upper and the lower dental arches. The interarch relationships, including the anterior and the canine guidance, and the posterior relationship between the centric cusps and the buccal-occlusal and lingual-occlusal marginal ridges depends on good coordination between the upper and lower arches,5–8 as well as the in-out prescription of the orthodontic appliance (Figs 1.12 & 1.13). The Clarity™ SL Self-Ligating brackets have been manufactured with this relationship in mind, which allows the simultaneous use of conventional appliances and the SmartClip Self-Ligating appliance in the same patient during orthodontic treatment (see Figs 1.5, 1.6 & 1.7).

Slot depth

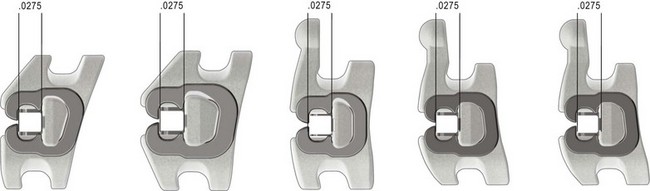

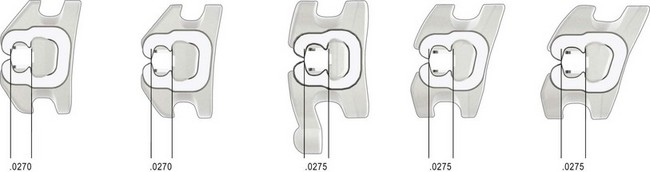

As mentioned above, the Clarity™ SL Self-Ligating appliance is a passive appliance, that is, the clip does not exert active pressure on the archwire, unless it is required, e.g. to correct rotations. This allows the use of lower forces during the alignment and the leveling stages of treatment (Figs 1.14, 1.15 & 1.16).9,10 These stages are completed when the bracket slot is fully filled by the orthodontic archwire in the horizontal plane. The .019/.025 rectangular archwire (Fig. 1.17) or an .016 archwire overlapping the .014 round Nitinol archwire should be engaged on the same visit (see Figs 1.34, 1.35 & 1.36 below).

The depth of the Clarity™ SL Self-Ligating appliance slot measures .0270 inches between the clip and the bottom of the bracket slot in the lower incisors, and .0275 inches in the remaining teeth. This has been done in order to have improved rotational control at the beginning of treatment (Figs 1.18 & 1.19).

Sliding mechanics with the Clarity™ SL Self-Ligating Appliance

The principle of sliding mechanics4,5,11,12 can be applied without any need for compromise when using the Clarity™ SL Self-Ligating brackets. The metal slot allows precise accomplishment of aligning, leveling, space closure, and finishing and detailing.

When the orthodontic archwire is allowed to slide freely within the bracket slot in the aligning stages, the masticatory and the muscle forces work in harmony with the applied biomechanics with low force levels, and thus a favorable biological response (Figs 1.20 & 1.21).

Aligning

Alignment is the first stage of orthodontic treatment and, depending on the severity of crowding, a .014 round Nitinol or other superelastic archwire can be used regardless of the case being extraction or non-extraction. A .022/.028 bracket provides greater flexibility to .014 archwires, enabling perfect archwire engagement and disengagement using the Nitinol clips (Figs 1.22, 1.23 & 1.24).

In non-extraction cases, space can be created by proclination or stripping of the incisors, expansion of the intercanine, interpremolar or intermolar width, and distalization or stripping of the posterior teeth. The choice of procedure will depend on the orthodontic treatment plan, incorporating the dental visual treatment objective (dental VTO) analysis.13

In premolar extraction cases, the canines should be retracted with lacebacks (which consist of .009 ligature wires), to open up space for the alignment of the incisors (Figs 1.25 & 1.26).

Leveling

In extraction cases, leveling should be initiated after the retraction of the canines opens up spaces for the alignment of the incisors (Figs 1.27, 1.28, 1.29 & 1.30).

Leveling can be performed using two archwire sequences:

As mentioned above, the Clarity™ SL Self-Ligating .022/.028 bracket has a .0270 inch slot depth between the Nitinol clips and the bottom of the bracket slot for the lower incisors, and .0275 inch slot depth for the remaining teeth. This may seem as if there is not enough space to engage both wires horizontally (Fig. 1.37). However, when engaging the second wire, one wire slides cervically and the other wire slides occlusally, thereby completely filling the bracket slot both vertical and horizontally (Fig. 1.38). The .014 archwire overlying the .016 archwire in the lower anterior brackets is equivalent to a single .021 archwire (Fig. 1.39). Thus, this simultaneous use of two round archwires provides a very efficient mechanism for correcting rotations, angulations and leveling of the bracket slots. Moreover, with this archwire technique, after the leveling and the alignment stages, a .019/.025 rectangular Nitinol or stainless steel archwire can be used as the next archwire. The space-closing biomechanics can therefore be applied earlier in the treatment (Figs 1.40, 1.41 & 1.42).

Fig. 1.38 Figs 1.37 & 1.38 A .014 and a .016 archwire inserted together results in a total wire diameter greater than the depth of the bracket slot. However, in practice, as shown in Figure 1.38, the force of engagement of the second wire directs one wire to the occlusal and the other to the cervical, thereby completely filling but not exceeding the bracket slot depth.

Space closure

To assist with optimal expression of the torque, .009 passive ligatures should be used from the hooks on the archwire on the mesial of the canines to the hooks on the first or second molar buccal tube along with the .019/.025 rectangular archwires. This should be done 30 days before initiating the sliding mechanics (Fig. 1.43). With the SmartClip™ Self-Ligating appliance, it is recommended that sliding mechanics should not be used in the stages prior to the space closure stage of treatment.

After the torque has been expressed, sliding mechanics can be initiated in both extraction and non-extraction cases. Again, hooks placed on the mesial of the canine on the archwires should be used to engage the retraction system anteriorly. The hooks can be welded in the office or may be supplied prewelded to the orthodontic archwire12,14 (Figs 1.44 & 1.45).

Space closing mechanics can be carried out with elastic modules and ligatures or Nitinol springs15,16 (Figs 1.46 & 1.47). The elastic modules used with ligatures or the Nitinol coil springs should remain in place from the start to the finish of space closure and for one additional month after space closure. The aim is to ensure that the roots are positioned in accordance with the angulation and torque values built in the brackets.

Finishing and detailing

Finishing of the orthodontic treatment5,6,17,18 with a .019/.025 rectangular stainless steel archwire is recommended after tridimensional control of each tooth has been achieved – angulation, inclination and rotation (Figs 1.5, 1.6 & 1.7). The occlusion is checked in centric relation, as well as the functional movements to check anterior guidance in protrusive excursions, and canine guidance in lateroprotrusive excursions (Figs 1.48, 1.49, 1.50, 1.51, 1.52, 1.53, 1.54, 1.55 & 1.56). At this time, a .019/.025 rectangular braided archwire should b/>

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses