Chapter 4

Non-aesthetic restorative materials

DENTAL AMALGAM

Definition

Dental amalgam is a permanent posterior restorative material that consists of silver alloy (silver, tin and copper) and mercury. Amalgam is supplied in encapsulated form and appears silver in the mouth. The mercury used within dental amalgam is a liquid metal (at room temperature) and is used to wet and bind the silver alloy once mixed. Once triturated with the metal, it forms a small, pliable material suitable for packing/condensing into the cavity preparation. Dental amalgam should always be used in conjunction with rubber dam to reduce the risk of inhalation in the event of accidental displacement (best practice). The mercury used in dental amalgam is minimal and should not pose a hazard to dental staff; however, care must be taken to not inhale the fumes, or have prolonged periods of skin contact, as this has been proven to be a health hazard (see Special considerations for working with dental amalgam).

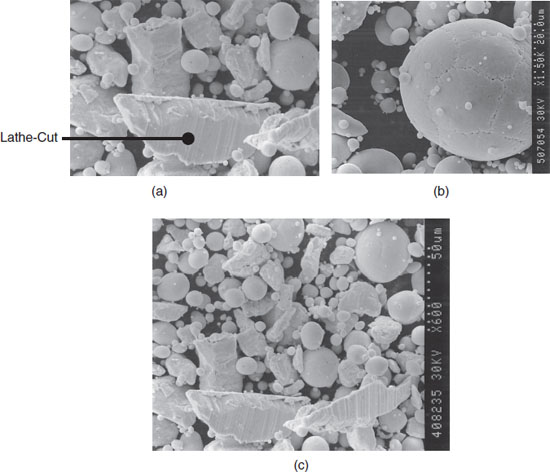

Amalgam alloys are classified by their composition and particle shape. Lathe-cut alloy (Figure 4.1a) is made up or irregular-shaped alloy particles. Spherical alloy (Figure 4.1b) is made up of spherical shaped alloy particles and requires less mercury to bind the materials due to its smoothness. Admixed alloy (Figure 4.1c) is a mixture of both spherical and lathe-cut particles. Operators often choose a spherical or admixed alloy, as the spherical particles act as reinforcers and can be more closely packed, resulting in a higher strength amalgam. The amount of copper in amalgam classifies it as either a high- or low-copper amalgam. High-copper amalgams are preferred as they reduce the amount of corrosion and marginal breakdown in the oral cavity produced by the tin–mercury product gamma 2 (γ 2) present in low-copper amalgams.

Figure 4.1 (a) Lathe-cut alloy. (b) Spherical alloy. (c) Admixed alloy (photo courtesy of SDI).

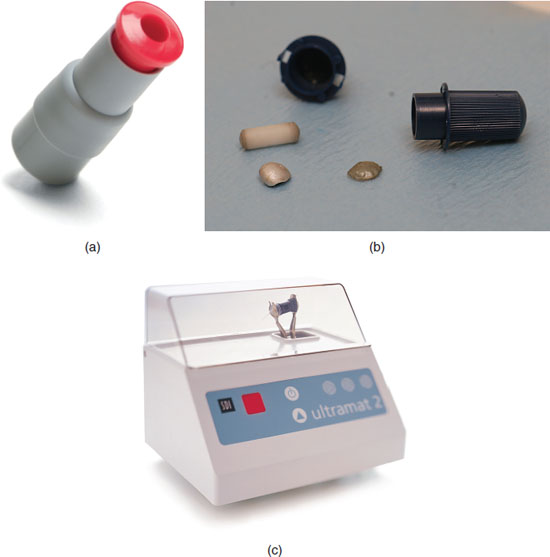

An amalgam capsule (Figure 4.2a) contains silver alloy, mercury, a mixing pestle and a plastic bubble (Figure 4.2b). The plastic bubble separates the silver alloy and mercury until the user activates the capsule (depending on the manufacturer, the capsule may be squeezed, twisted or activated using a device supplied by the manufacturer). The function of the pestle is to mix the silver alloy and mercury together. Once the amalgam capsule is activated, it is placed in the amalgamator for trituration. Trituration is the process in which the amalgam capsule is shaken for a defined period of time and speed in order to mix the silver alloy and mercury to the desired consistency. The amalgamator (Figure 4.2c) triturates the capsule to uniformly mix the silver alloy and mercury, which results in a putty-like mix that can be manipulated and placed into the cavity preparation, allowing the operator sufficient time to condense (pack), carve and burnish (smooth) the material. The manufacturer’s instructions should be followed in relation to the mixing time of the amalgam, as trituration time and speed may affect the properties of the amalgam.

Figure 4.2 (a) Amalgam capsule. (b) Amalgam capsule contents. (c) Amalgamator.

Dental amalgam capsules contain ‘spills’ of amalgam; a spill refers to the amount of material contained in the capsule. The capsules may be colour coded to help users distinguish between spills. Spills are referred to by numbers, i.e. 1 spill = a single mix (600 mg), 2 spills = a double mix (800 mg), etc. Three spill sizes are available (size may vary depending on the manufacturer). It is the operator that will request the spill of amalgam needed, which corresponds to the size of the cavity preparation to be filled. Amalgam may be purchased in bulk quantities or smaller ones (Figure 4.3).

Figure 4.3 Amalgam packaging in bulk and small quantities.

An amalgam waste container (Figure 4.4) must be used to ensure safe and proper disposal of excess dental amalgam. Separate containers are available for the excess amalgam and the amalgam capsule. The amalgam waste container is an airtight container that contains a foam insert containing non-hazardous chemicals (oxidising agent or activated charcoal) meant for suppressing mercury vapours.

Figure 4.4 Amalgam waste container.

Material constituents/composition

| Silver alloy | Mercury |

| Silver | Mercury |

| Tin | |

| Copper | |

| (Sometimes zinc) |

Properties

- The strength of amalgam is dependent on the type of amalgam (spherical, high copper, etc.)

- Amalgam reaches its final compressive strength after 24 hours (this may depend on amalgam types; e.g. a high-copper amalgam may reach its final compressive strength quicker)

- If occlusal forces are placed on amalgam too early post placement, there is a greater risk of fracture

- May be used in conjunction with a bonding agent to micromechanically adhere amalgam to the/>

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses