CHAPTER 26 Implant Prosthodontics: Overdentures and Their Mesostructure Bars

The preoperative procedure of making a surgical template (see Chapters 4 and 20) should serve as a guide for the placement of a bar or implants designed to hold a bar in the optimum position. The template can be used at the time of surgery to guide the placement of transosteal, blade, and root form or ramus frame implants, at least within the limits of the available bone. It also can be used after implant integration to guide placement of the bar. Furthermore, after making a template, the dental surgeon may realize that the procedure must be abandoned entirely because prosthetic restoration is not possible.

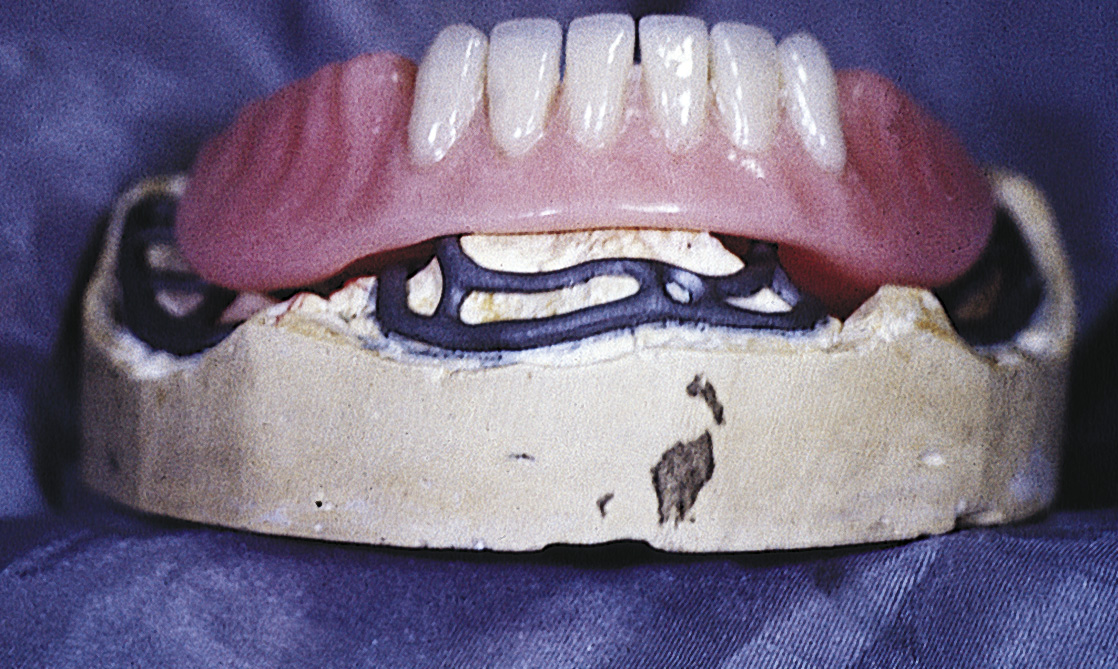

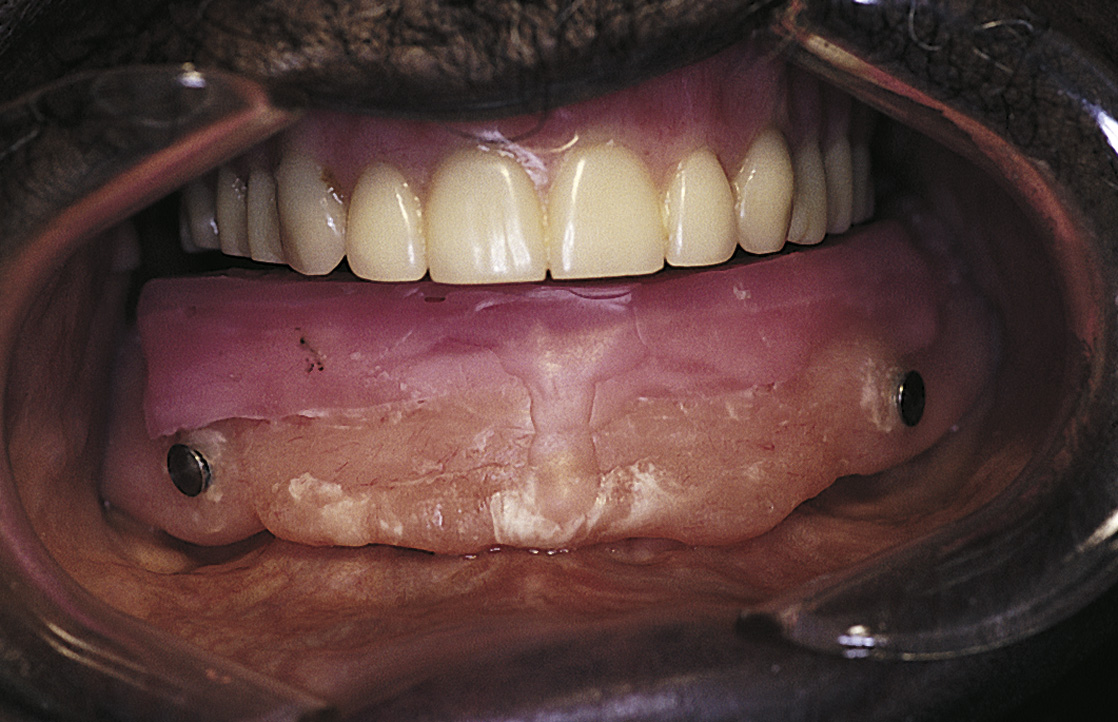

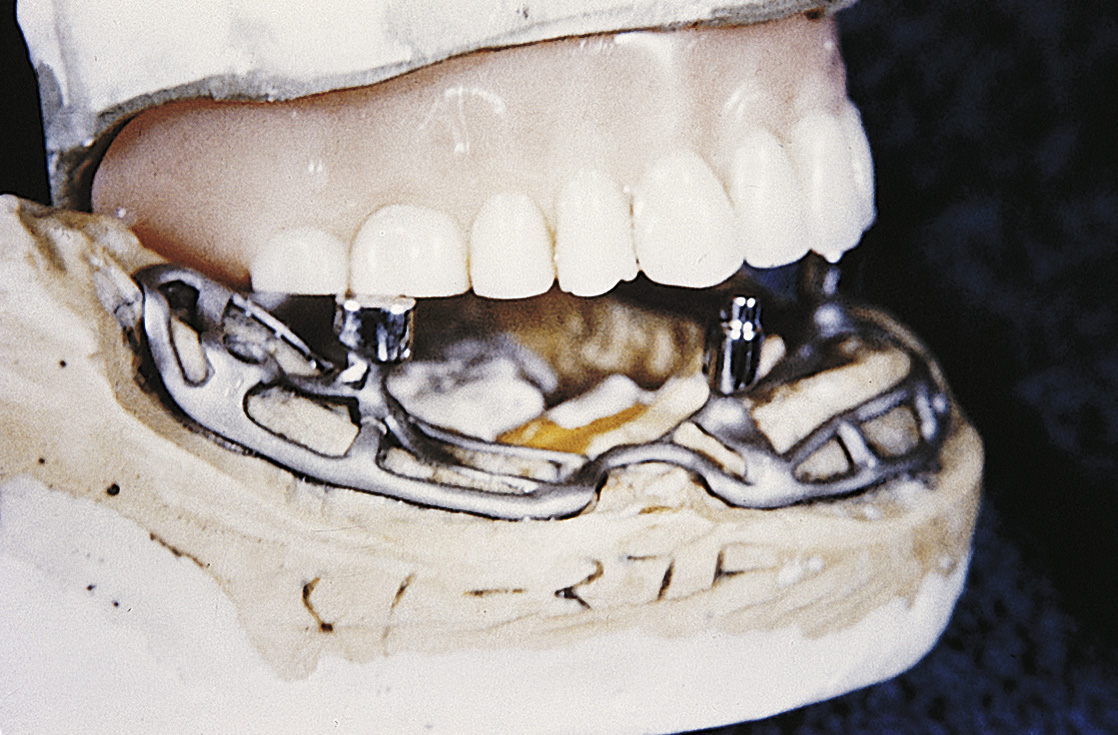

If a complete subperiosteal casting is planned, the clear surgical template should be placed over the bone model (although its fit is only approximate) to guide bar placement by the laboratory. If the computer-aided design/computer-aided manufacture (CAD/CAM) or stereolithographic method was not chosen, then at the time of first-stage surgery, an impression is made of the opposing arch and a wax or Optosil putty interocclusal recording with the bone exposed at the correct vertical dimension and centric relationship (Fig. 26-1). This allows accurate mounting of the bone model and proper placement of the abutments (Fig. 26-2). CAD/CAM technology creates a more significant problem, because even the most splendidly executed cast is returned without its relationship to the opposing jaw (although the CAD/CAM section in Chapter 14 provides a solution to this problem). The tube and stylus technique ensures accurate placement of the bar or abutment.

FIGURE 26-2. Mounted casts using the acquired relationship allow accurate placement of abutments or a Brookdale bar.

Chapter 5 explains bar attachment designs. If the bar is to be made separately from the implants, it should be the fixed-detachable or cemented type and should be fabricated in accordance with the techniques outlined in Chapters 24 and 25. Of course, a bar may also be a part of the implant infrastructure casting, as with ramus frame and subperiosteal designs.

FULL SUBPERIOSTEAL IMPLANTS

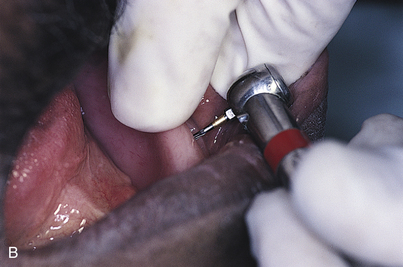

If centric relationship and vertical dimension records were taken at the first stage of bone surgery, the laboratory can articulate the bone impression model reliably. Once the impression model has been articulated, the information needed to fabricate the implant is available, and an interim or temporary denture can be made for the patient (Fig. 26-3). The surgeon may insert this at the time of surgery and use it during the healing period (Fig. 26-4).

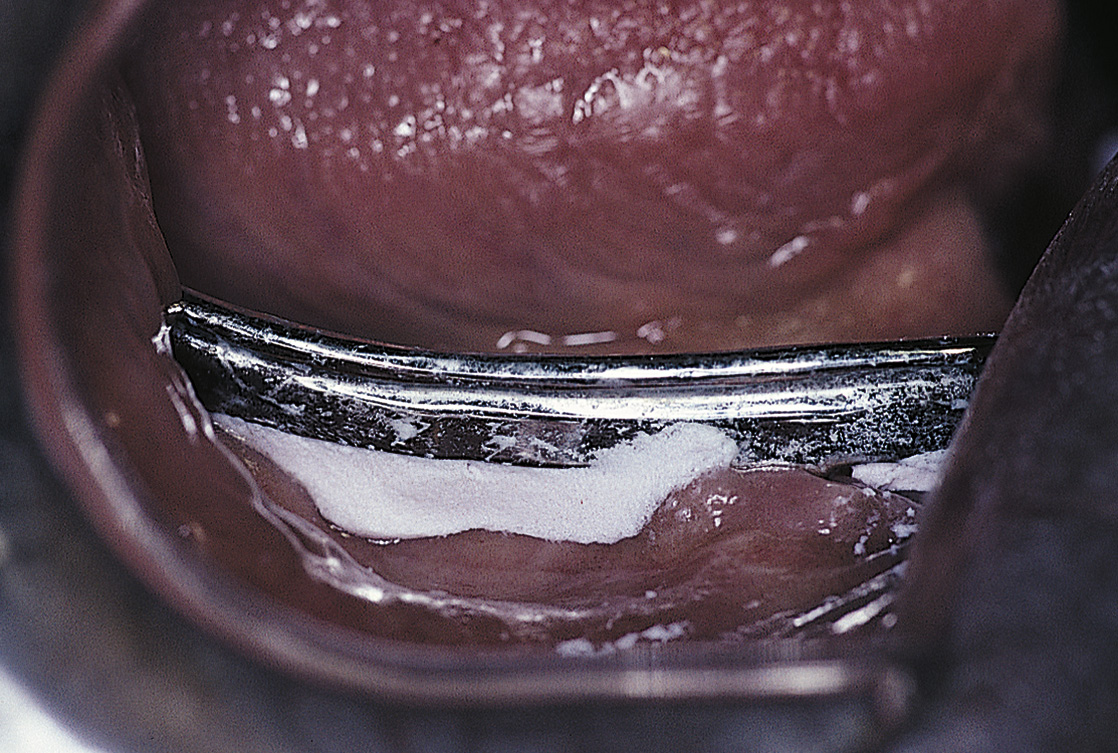

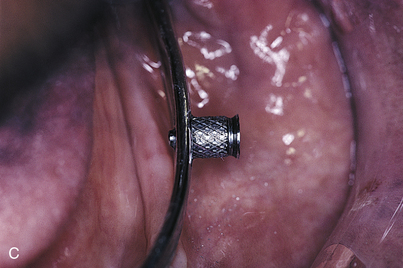

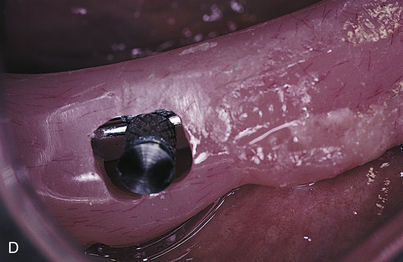

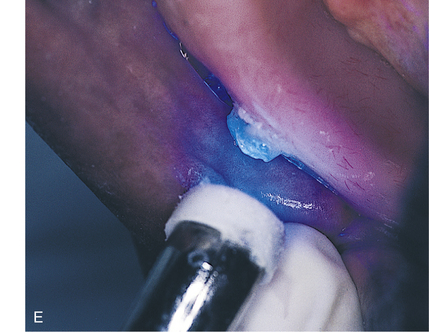

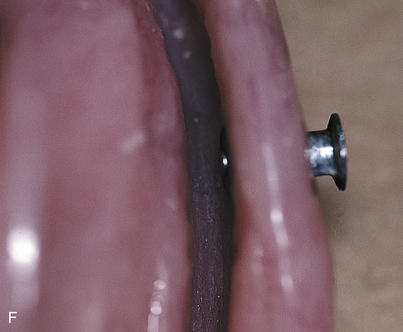

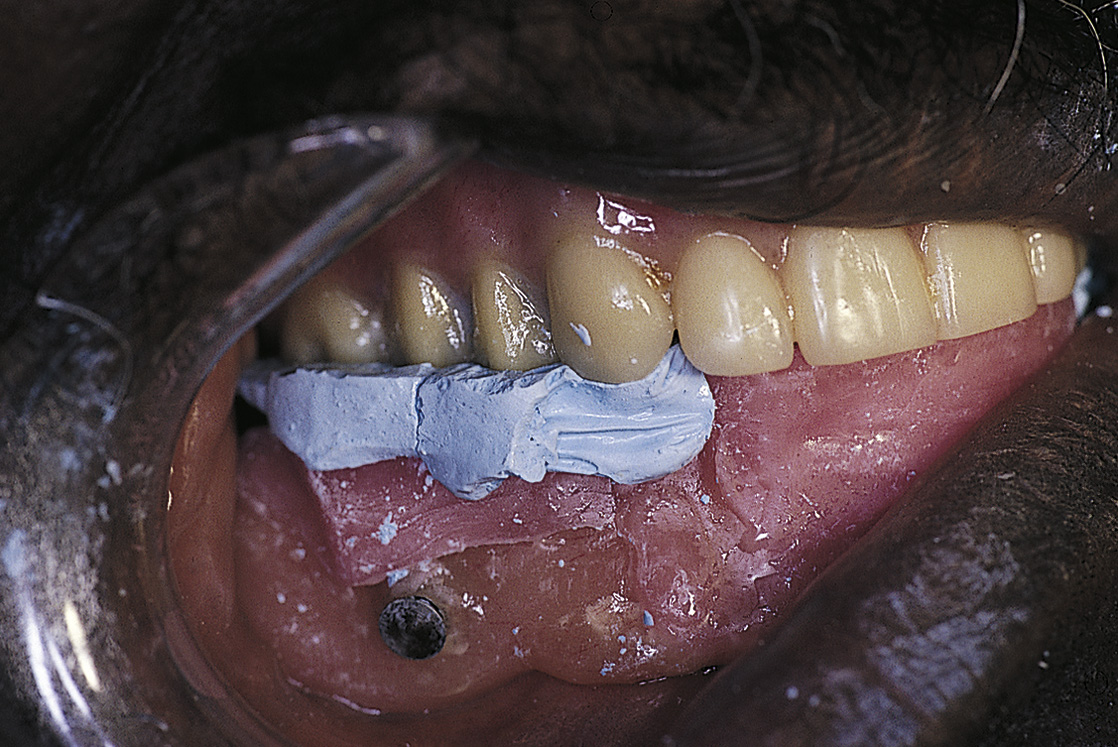

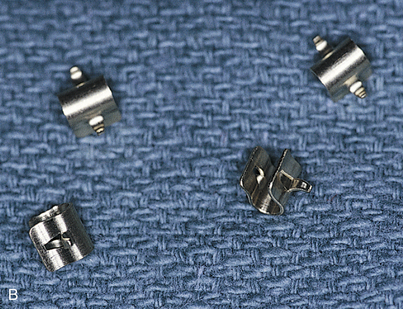

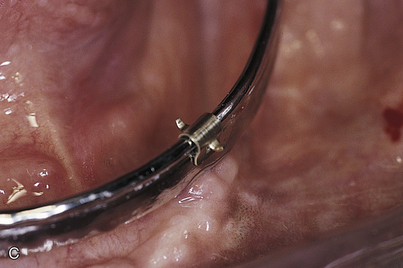

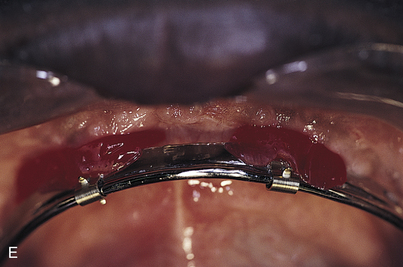

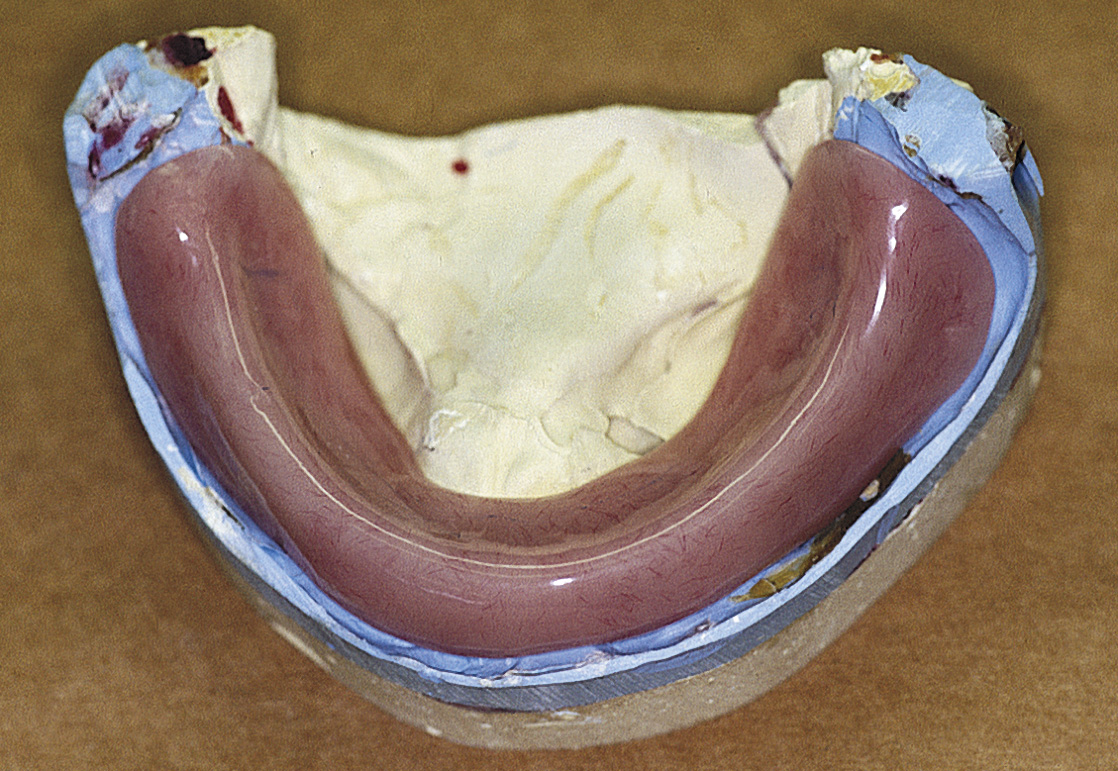

During the impression procedure, care must be taken not to lock material under the bar or force material beneath the tissues surrounding the implant cervices. The area under the bar should be blocked out with a soft wax (e.g., periphery wax) or block-out material and the impression is then made with an alginate material in a stock tray (Figs. 26-5 and 26-6). The impression is poured with die stone, and the cast is used to fabricate a custom tray (Fig. 26-7). This tray is used to record the final impression, which is done with an elastomer (e.g., Impregum), and for which the areas under the bar again are blocked out (Fig. 26-8). The final cast is made of an epoxy material using the centrifuge technique to ensure accuracy, density, and strength (Fig. 26-9). This method ensures a detailed duplication of the bar and its retention devices, such as Locator attachments, O-rings, trailer hitches, or Zest anchors.

FIGURE 26-5. Blocking out undercuts beneath the bar with periphery wax facilitates impression making.

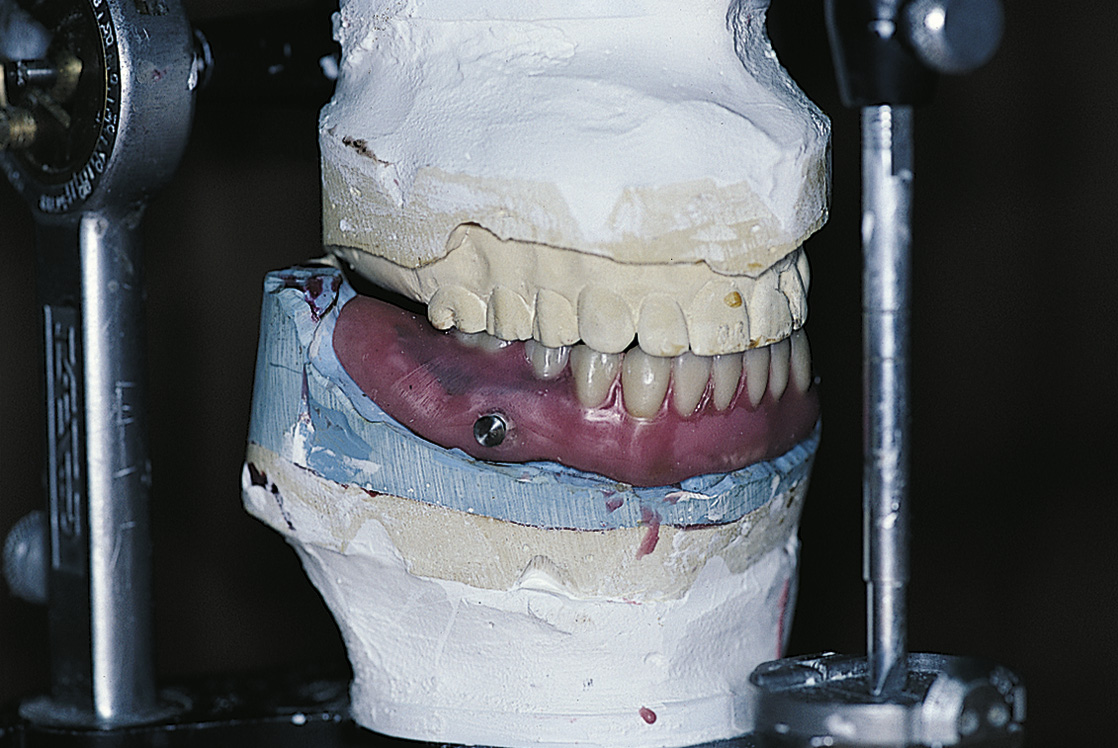

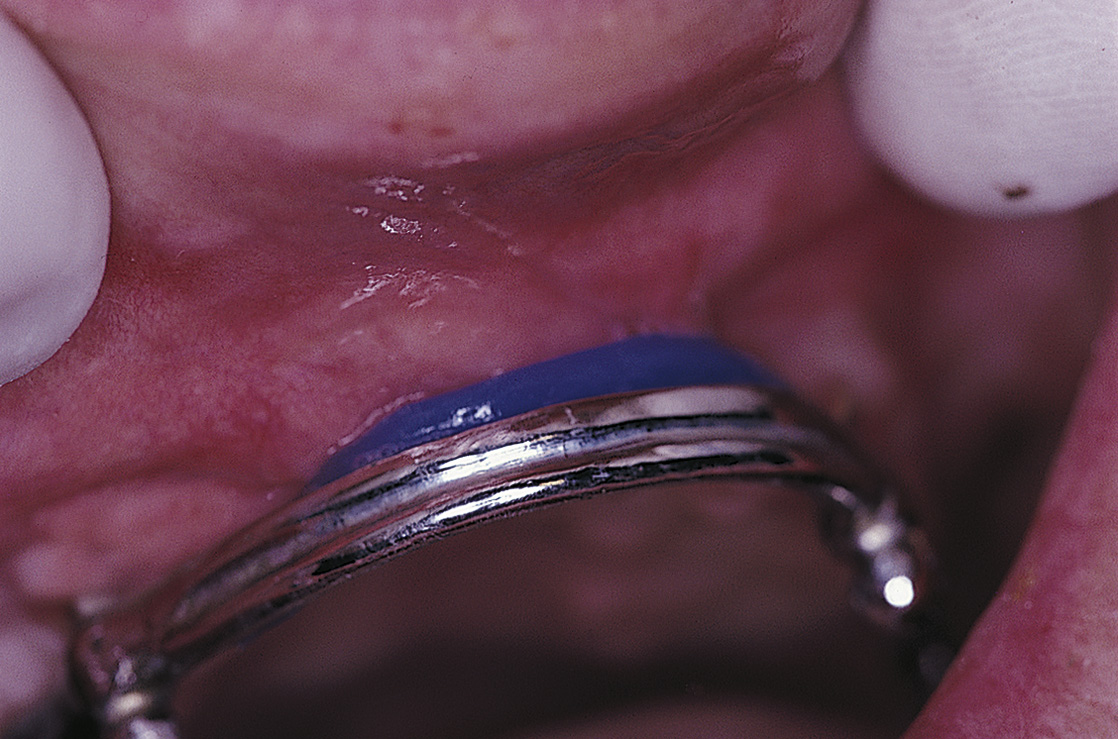

Next, an acrylic, heat-cured, final denture base is made to establish the maxillomandibular records (Fig. 26-10). If retentive devices are to be used as the means of attachment, the laboratory should incorporate them into the base so that its final position allows accurate records to be made (Figs. 26-11 and 26-12). If the trial setup is satisfactory, this base is used as the final one onto which the teeth are processed (Figs. 26-13 to 26-15).

FIGURE 26-10. A heat-cured polymethylmethacrylate final denture base is the most accurate means of acquiring records.

FIGURE 26-15. The base plates are transferred to a semiadjustable articulator. Facebow mounting contributes to accuracy.

Zero-degree acrylic denture teeth are used to minimize oblique and lateral forces that are transmitted to the implant (Figs. 26-16 and 26-17).

UNIVERSAL SUBPERIOSTEAL IMPLANTS

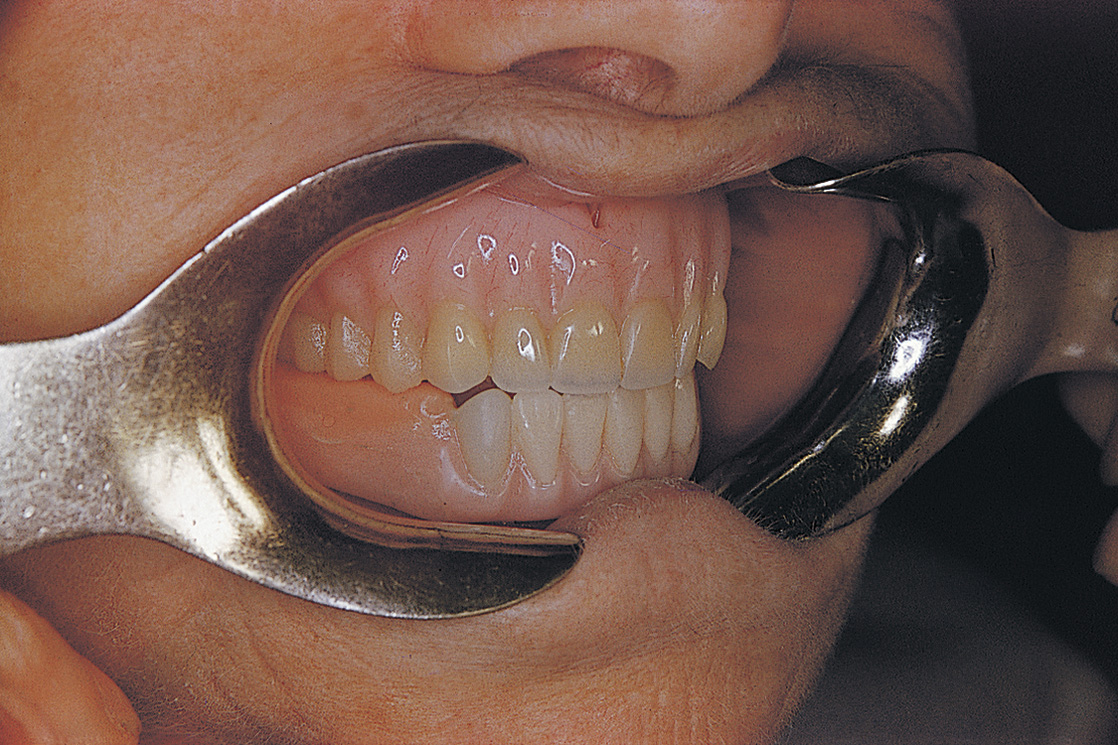

The universal (or bilateral) subperiosteal implant is a full arch casting that is placed with natural teeth, which the prosthesis’ peripheral struts circumvent. The usual reconstructive technique is an overdenture with cast gold copings placed on the natural teeth (Figs. 26-18 to 26-20).

FIGURE 26-18. A universal subperiosteal implant is managed by splinting the patient’s remaining four mandibular incisors with gold copings.

FIGURE 26-19. The overdenture is relined. When necessary, it may be used with or without a bar, depending on retention requirements.

Telescopic copings are made on the natural teeth after the tissues have healed. If these copings are placed before healing is complete, gingival recession occurs at their margins. If a single-cast gold coping splint is cemented for the natural teeth, standard impression techniques are used to fabricate the overdenture. The bases for anchorage of natural teeth and subperiosteal implant abutments are dissimilar; therefore a one-piece coping bar splint is not advisable. Individual gold copings protect the natural teeth from caries and facilitate hygiene procedures.

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses