12

Endopore® Dental Implant System

BASIC FACTS

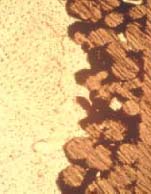

The Endopore® dental implant was designed at the University of Toronto by Drs. Deporter, Watson, and Pilliar and was first used in humans in 1989. This implant has a five-degree truncated shape and is made of a high-strength Ti6Al4V alloy cone with a multi-layer porous surface over most of its length. The porous surface is achieved by sintering spherical particles, which create the possibility of three-dimensional bone ingrowths (Figure 12.1–12.3).

FIGURE 12.2.

The Endopore® dental implant is available in two different implant abutment connection forms.

External Connection

(Refer to Figure 12.4)

- 1mm polished collar

- 2mm polished collar

A polished collar between the prosthetic platform and porous surface ensures the health of the gingiva. The Endopore® dental implant with a 2mm polished collar is the preferred choice.

Internal Connection

(Refer to Figure 12.5)

- 1.8mm transgingival collar

- 2.8mm transgingival collar

Bone is directly opposed to and extends in between the sintered particles on the surface of the implant. The Endopore® dental implant engages with the alveolar crest by cortical bone growth into its porous surface. During function, the occlusal forces are transferred to the crestal bone area, and this eventually stimulates further cortical bone development.

Because the porous design greatly increases the surface area at the interface between the bone and the implant, a shorter implant can be used. A shorter implant helps the patient and clinician avoid some expensive bone augmentation procedures such as sinus lifts.

MECHANICAL RATIONAL FOR SHORT ENDOPORE® DENTAL IMPLANTS

The resulting mechanical interlocking of bone and implant at the interface provides a very effective means of force transfer between the implant and the peri-implant tissues, including the ability to effectively transfer the tensile forces. Both the axial and transverse force components (tensile, shear, and compressive) acting on the implant are effectively resisted, resulting in a more uniform distribution of mechanical stresses in the peri-implant bone. As a result, peak stresses next to the most coronal portion of the porous-surfaced implant are significantly lower than the stresses that would occur with a threaded implant, because the forces are distributed more uniformly with a porous implant.

The porous-surfaced implants possess a unique ability to effectively resist the tensile forces acting at the implant-bone interface, resulting in a more favorable response.

Advantages of the Endopore® Dental Implant System

- Three dimensional interlocking of the bone with the implant surface

- Predictable and minimal crestal bone remodeling

- Eliminates the need for bone grafting in the patient with compromised bone height

- Tapered design and press-fit insertion technique is ideal for patients with a split ridges technique treatment planned

- Uncomplicated surgical sequence; only two drills are used to prepare the implant bed

- Expanded overdenture attachment options

Surgical Steps

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses