Orthodontists use a wide range of materials during patient care; therefore, the performance of the available materials is of great importance. Orthodontic materials are initially tested in the laboratory, and, if performance and safety are satisfactory, they are considered for use in clinical practice. Orthodontic materials include the various orthodontic brackets such as metal, plastic, and ceramic; wires such as stainless steel, beta-titanium alloy, and nickel-titanium; mini-implants; elastomerics; and orthodontic cements and composites ( Table I ).

| Bond strength: adhesives and cements, priming methods (conventional vs self-etching), bracket mesh, curing method, sandblasting |

| Bracket strength (ceramic, metal, plastic) |

| Frictional forces of various brackets, wires, and their combinations |

| Wire and coil forces and moments, wire fracture |

| Relaxation of elastomers |

| Leaching from materials: fluoride, nickel, and di-phenol |

| Biofilm formation |

| Factors influencing implant stability |

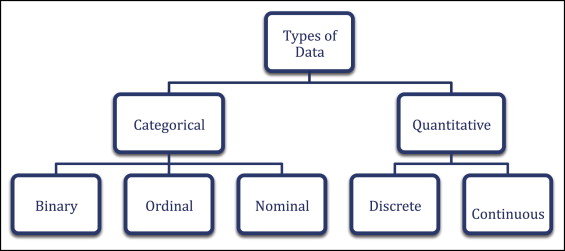

An experiment can be designed to investigate the bond strength of 2 types of adhesives or 2 types of brackets because the design of the latter can influence the outcome. Such a design might be investigated in vitro first and then in vivo, since results from laboratory studies do not always accurately translate to clinical practice. To analyze such a study at the in-vitro level, we will record the outcome, which will be a continuous scale ( Fig 1 ). Then we will calculate the mean force of debonding for each of the 2 adhesive groups and perform an independent t test to compare them, if the outcome per group is normally distributed and their variances are equal. If our outcome is not normally distributed, we will use an equivalent nonparametric test (Wilcoxon rank sum or Mann-Whitney test) ( Table II ). The t test, if valid, is preferable because it allows estimation of the effect and the corresponding confidence intervals, whereas the nonparametric test is more for hypothesis testing—ie, to obtain a P value.

| Measurement scale | Two independent treatment groups | Three or more independent groups | Before and after 1 treatment in the same person | Multiple treatments in the same person |

|---|---|---|---|---|

| Continuous (normally distributed) ∗ | Unpaired t test | ANOVA (2-way ANOVA if >1 categorical variable is included) | Paired t test | Repeated-measures ANOVA |

| Nominal | Chi-square or Fisher exact test | Chi-square | McNemar test | Cochrane Q |

| Ordinal | Mann-Whitney rank sum | Kruskall-Wallis | Wilcoxon signed rank test | Friedman statistic |

| Survival time | Log rank test |

∗ If normality is not met, rank the observations and use methods for ordinal scale.

Parametric survival analysis by using the Weibull distribution has been suggested as a more appropriate model for analyzing bond failures. Since the achieved bond strength is usually higher than the recommended minimum values, the lower tail of the distribution, which includes the lowest stress values that result in failure, is important. The Weibull simulates well the extreme values that are not normally distributed and has been used extensively in aerospace engineering and in the prediction of failure of airplane components. The probabilities of bond failure from the tails of the distribution can be calculated, thus indicating the probability of failure at various stress levels and especially the probability of failure at lower stress levels.

The comparison of the 2 adhesives or 2 bracket types could be further explored in vivo in a prospective study in which similar patient groups in terms of baseline characteristics are included. An alternative scenario might be a split-mouth design in which both adhesives are bonded in all patients. The split-mouth design has the advantage of decreased variability of the outcome, because patients act as their own controls. In the in-vivo studies, it is difficult to measure bond strength; however, we can measure the number of failures. These data can be simply analyzed by using a chi-square test in which we are trying to assess whether there is an association between type of adhesive and number of failures. The chi-square test gives a P value that shows the probability of observing such a difference in failures between adhesives or a more extreme one, when the null hypothesis is true. The chi-square test does not give effect estimates and confidence intervals, which are more meaningful in terms of comparing the effectiveness of the 2 adhesives.

More advanced approaches include logistic regression, Poisson regression, or Cox proportional hazards (survival analysis) tests ( Table III ). Logistic regression gives an estimated odds ratio and compares the odds of failure of one adhesive vs the other. Poisson regression and Cox proportional hazards incorporate a time element and give estimates as rate ratios or hazard ratios, respectively, and they indicate how quickly or slowly the events occur. In general, Poisson regression is more appropriate when the event rate is low and constant; Cox proportional hazards is used when the events occur quickly or are not constant. Cox proportional hazards allows intervention group rates to vary as long as the hazard ratio is constant (proportional hazard assumption).