Introduction

There has been continuing interest in the development and use of esthetic and effective orthodontic archwires. The aims of this study were to evaluate the inner alloy core dimensions of 4 brands of as-received esthetic coated wires and their mechanical properties before and after 21 days of oral exposure, compared with conventional stainless steel and nickel titanium wires.

Methods

Four groups (Ortho Organizers, Carlsbad, Calif; TP Orthodontics, LaPorte, Ind; Orthometric, Beijing, China; and Trianeiro, Rio Claro, São Paulo, Brazil) of orthodontic archwires were tested. Five properties were evaluated: inner wire dimensions, modulus of elasticity, modulus of resilience, maximum deflection force, and load deflection curve characteristics. Images of the transverse sections from the specimens were made with a stereoscope. The inner alloy core dimensions of each wire were measured by using Image Pro Plus software (version 4.5; Media Cybernetics, Silver Spring, Md). All specimens were tested in a universal testing machine in a 3-point bending test.

Results

Coated wires of the Ortho Organizers and Trianeiro groups showed greater reductions in their inner alloy core dimensions and produced lower loading and unloading forces and lower modulus of elasticity, modulus of resilience, and maximum deflection force values than did their control wires. Inner alloy core dimensions and the mechanical behavior of coated wires practically did not differ from the control wires in the TP Orthodontics and Orthometric groups.

Conclusions

The reduction on the inner alloy core dimensions to compensate for the coating thickness seems to be the variable responsible for greater changes in the mechanical properties of esthetic coated wires.

Much progress has been made in the development of esthetic clear and translucent brackets for use in labial orthodontics. However, the most effective wires continue to be manufactured from efficient metal alloys. They have the flexibility, strength, and chemical resistance needed for orthodontic purposes. Nevertheless, they are clearly visible to observers, and patients with esthetic brackets might resist their use.

Metallic archwires coated with colored polymers or inorganic materials are currently the solution to this esthetic problem. Materials used in coating are polymers such as synthetic fluorine-containing resin or epoxy resin composed mainly of polytetrafluoroethylyene, which is used to simulate tooth color.

The process of applying this coating to the archwire includes some surface treatment on the wire and the use of clean compressed air as a transport medium for the atomized polytetrafluoroethylyene particles to coat the wire. The set is further heat treated in a chamber furnace. The mechanical properties of metallic archwires could be affected during this process and by possible changes on their inner alloy core dimensions to compensate for the thickness of the coating layer.

The mechanical properties of orthodontic archwires can be assessed by using a 3-point bending test, which evaluates the load-deflection properties, considered the most important parameters to determine the biologic nature of tooth movement, and provides information on the behavior of wires when subjected to deflection in the horizontal and vertical directions. No studies have been conducted to examine the inner alloy core dimensions of esthetic coated stainless steel and nickel-titanium archwires and their mechanical properties after oral exposure.

The aims of this research were to investigate the inner alloy core dimensions of as-received esthetic coated archwires and their mechanical properties (3-point bending test) before and after oral exposure, compared with conventional stainless steel and nickel-titanium archwires.

Material and methods

Sample size calculations were performed for each test. A sample size of at least 5 wire segments per group was required to detect a difference of 0.001 of an inch in the dimensions between the coated and the control wires, with a standard deviation of 0.0006, a significance level of 5%, and a test power of 0.85. Based on the results from a pilot study, a sample size calculation was performed showing that at least 5 as-received and 10 postclinical wire segments would be enough to detect a 10% difference in the mechanical properties tested in this study with a significance level of 5% and a test power of 0.85.

Four brands of esthetic coated archwires (Ortho Organizers, Carlsbad, Calif; TP Orthodontics, LaPorte, Ind; Orthometric, Beijing, China; and Trianeiro, Rio Claro, São Paulo, Brazil) were tested, and their respective control counterparts (conventional stainless steel and nickel-titanium archwires) were evaluated ( Table I ). The sample included 176 wire segments at least 20 mm in length. Eighty wire segments were from as-received archwires (5 specimens of each kind of wire used to measure the inner alloy core dimensions, and 5 were used in the 3-point bending test), and 96 segments (12 specimens of each kind of wire used in the 3-point bending test) were retrieved after 21 days in oral cavities.

| Group | Manufacturer | Cross-section size (in) | Composition | Coating surface |

|---|---|---|---|---|

| I | Ortho Organizers, Carlsbad, Calif | |||

| Control: Pro Form Shiny Bright | 0.018 × 0.025 | Stainless steel (CrNi) | – | |

| Coated: Tooth Tone Plastic Coated | 0.018 × 0.024 | All surfaces | ||

| II | TP Orthodontics, LaPorte, Ind | |||

| Control: Shiny Bright | 0.018 × 0.025 | Stainless steel (CrNi) | – | |

| Coated: Aesthetic Shiny Bright | 0.018 × 0.025 | Labial | ||

| III | Orthometric, Beijing, China | |||

| Control: Flexy Super Elastic | 0.018 × 0.025 | NiTi | – | |

| Coated: Esthetic Flexy Super Elastic | 0.018 × 0.025 | Labial | ||

| IV | Trianeiro, Rio Claro, São Paulo, Brazil | |||

| Control: NiTi wire | 0.016 × 0.022 | NiTi | – | |

| Coated: Coated wire NiTi | 0.018 × 0.024 | All surfaces |

The retrieved wire segments were obtained from 12 subjects. Ethical approval was obtained for this investigation from the ethics in research committee of the Institute of Public Health Studies from the Federal University of Rio de Janeiro in Brazil (process 0034.0.239.000-11). Informed consent form was signed by all patients who met the following criteria: good oral hygiene, no caries, and no systemic changes.

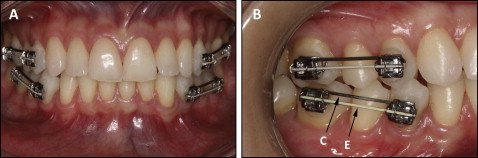

Two metal brackets (Morelli, Sorocaba, São Paulo, Brazil) were bonded to teeth on each hemiarch with a distance between them of at least 20 mm. The coated wire segment was tied into the slot, and its control wire segment was tied juxtaposed to the upper base of the brackets’ wings by using stainless steel 0.010-in ligatures (Morelli) and ligature pliers ( Fig 1 ). A split-mouth design was used in all groups. The groups were allocated randomly to each hemiarch by using random number tables. The generator and executor of the randomization were separate persons (C.T.M. and D.L.S.). Oral hygiene instructions were given, and the patients used the same types of toothbrush, toothpaste, and dental floss throughout the study. The subjects were told not to use any other oral agents, including oral irrigators or antimicrobial mouthrinses.

In every participant, the specimens were placed and removed by the same operator (D.L.S.). The subjects were not aware of which wire was placed in each quadrant in the mouth. Since the colors of the coated wires differed slightly from brand to brand, it was not possible to blind the operator to the types of coated wire.

After 21 days, the wire segments were removed and individually placed in an ultrasound cleaner (Cristófoli; Campo Mourão, Paraná, Brazil) immersed in a multiuse detergent (Amway, Ada, Mich) for 30 minutes, so that organic debris could be removed. The same procedure was used for the as-received specimens. After in-vivo clinical exposure, all samples were subjected to mechanical testing.

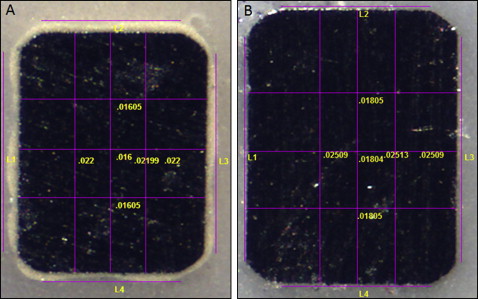

Five as-received wires were taken from each group and included, with their transverse section facing up, in plastic tubes (height, 10 mm; diameter, 5 mm) filled with light-curing composite resin (Monolok ; Rocky Mountain Orthodontics, Denver, Colo). Then the samples were ground in a water-cooled polishing machine (Politriz DP-9U2; Struers A/S, Copenhagen, Denmark) with 360-, 400-, 600-, and 1200-grit abrasive papers under refrigeration.

The images of the transverse section from each specimen were made with a stereoscope at 45 times magnification (model SZ61; Olympus, Tokyo, Japan). The inner alloy core height and width (3 measurements of each kind) of each wire were measured by using Image Pro Plus software (version 4.5; Media Cybernetics, Silver Spring, Md) ( Fig 2 ). A total of 60 readings, including height and width, were measured in each group.

The wires were tested according to a 3-point bending test (ISO 15841). The span length of 10 mm, the crosshead speed of 6.0 mm per minute, and the radii of the fulcrum and the indenter of 0.1 mm were used as suggested by the ISO standardization for orthodontic wire mechanical tests. The load was applied with a 50-N load cell in a universal testing machine (model DL 10000; Emic, Paraná, Brazil) to the middle of the specimens, and the flexural strength values were recorded with Tesc software (Emic). Deflection was carried out with a centrally placed indenter moved by a computer-controlled stepper motor. Five as-received and 12 postclinical specimens for control and coated wires of each group were tested for a deflection of 3.1 mm, the force was registered, and the hysteresis curves produced on the chart’s recorder were compared. For stainless steel wires, the testing was performed at room temperature, and for nickel-titanium wires at 37°C.

The modulus of elasticity was calculated in the linear portion of force-deflection curves of each specimen using the equation

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses