Impression Materials

Learning Outcomes

On completion of this chapter, the student will be able to achieve the following objectives:

• Pronounce, define, and spell the Key Terms.

• List the three types of impressions taken in a dental office.

• Describe the types of impression trays and their characteristics of use.

• Discuss hydrocolloid impression materials and their uses, mixing techniques, and application.

• Discuss elastomeric impression materials and their uses, mixing techniques, and application.

• Explain the importance of an occlusal registration and describe its use in a procedure.

Performance Outcomes

On completion of this chapter, the student will be able to achieve competency standards in the following skills:

• Mix alginate impression material at competency level.

• Take a maxillary and a mandibular preliminary impression at competency level.

• Competently mix a paste final impression material.

• Competently prepare an automix impression material.

• Take a wax bite registration.

• Prepare and assist in a closed bite registration procedure.

Electronic Resources

![]() Additional information related to content in Chapter 46 can be found on the companion Evolve Web site.

Additional information related to content in Chapter 46 can be found on the companion Evolve Web site.

![]() and the Multimedia Procedures DVD

and the Multimedia Procedures DVD

Key Terms

Agar (AG-ahr) Gelatin-type material derived from seaweed.

Alginate (AL-ji-nayt) Irreversible hydrocolloid material used for taking preliminary impressions.

Base Foundation or the basic ingredient of a material.

Border molding Closer adaptation of impression edges to the mucobuccal fold.

Catalyst (KAT-uh-list) Substance that modifies or increases the rate of a chemical reaction.

Centric (SEN-trik) Having an object centered, such as maxillary teeth centered over mandibular teeth in correct relation.

Colloid (KOL-oid) A suspension of particles in a dispersion medium such as water. Its two phases are sol and gel.

Elastomeric (ee-las-tuh-MER-ik) Material having elastic properties from rubber.

Hydro- Prefix meaning “water.”

Imbibition (im-bi-BI-shun) Absorption of water, causing an object to swell.

Occlusal (o-KLOO-sul; o-KLOO-zul) registration Reproduction of a patient’s bite with the use of wax or elastomeric material.

Syneresis (si-ner-E-sus) Loss of water, causing something to shrink.

Tempering (TEM-pur-ing) Bringing a material to a desired consistency.

Viscous, Viscosity (vis-KOS-i-tee) Physical property of a fluid related to resistance to flow.

There are a range of dental procedures in which impression materials are used to take an impression of the teeth and surrounding oral tissues. Impressions are a negative reproduction of those structures, and the model created from the impression is the positive reproduction of the structures. The type of impression material selected for a procedure will depend on how the impression will be used.

As a clinical assistant, you will be responsible for knowing what type of impression tray to prepare, what material to set out, and the proper mixing sequence to use for the procedure. Your role in this type of procedure will be to assist in taking the impression, or, as an expanded-functions dental assistant (EFDA), in the actual taking of the impression.

Classification of Impressions

The three classifications of impressions taken in dental procedures consist of preliminary, final, and occlusal, also referred to as a (bite) registration. The type of dental material selected by the dentist to take these impressions will depend on what will be constructed from the impression. This chapter describes hydrocolloid and elastomeric impression materials, as well as the bite registration materials regularly used for dental procedures.

Preliminary Impressions

Preliminary impressions are taken by the dentist or by the EFDA and are used to create a reproduction of the teeth and surrounding tissues. A preliminary impression is used for the following reasons:

Final Impressions

Final impressions are taken by the dentist and are used to produce the most accurate reproduction of the teeth and surrounding tissue. A final impression provides the dentist and the dental laboratory technician with essential information needed for the creation of indirect restorations, partial or full dentures, and implants.

Bite Registrations

Bite registrations are taken by the dentist or the EFDA to produce a reproduction of the occlusal relationship of the maxillary and mandibular teeth when the mouth is occluded. This provides the dentist and the laboratory technician with an accurate registration of the patient’s centric relationship between the maxillary and mandibular arches.

Impression Trays

Impression trays are used to hold the impression material within the mouth. These trays must be sufficiently rigid to (1) carry the impression material into the oral cavity, (2) hold the material close to the teeth, (3) avoid breaking during removal, and (4) prevent warping the completed impression.

Impression trays are of two basic types: stock trays and custom trays.

Stock Trays

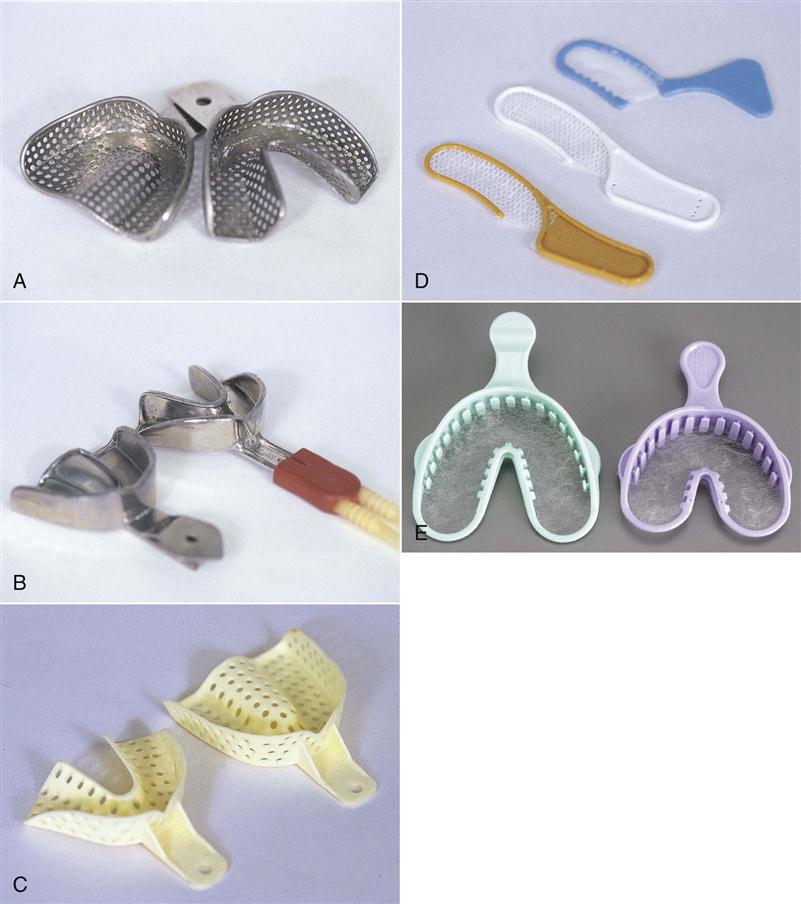

Stock trays are manufactured in several ways and are available in a range of sizes and styles. Fig. 46-1 illustrates the different types of stock trays that are used most often during a dental procedure.

Selection

Impression trays are selected for size by trying the tray in the patient’s mouth before taking the impression. The correct tray accomplishes the following:

Characteristics

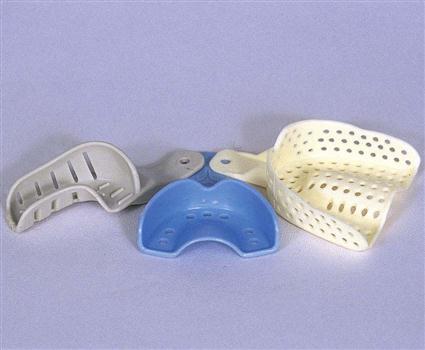

Impression trays are supplied in one of the following ways (Fig. 46-2):

• Quadrant trays, which cover half of an arch

• Section trays, which are used to cover the anterior portion of the arch

An impression tray is also characterized by whether the surface of the tray is perforated or smooth. When a perforated surface tray is used, the impression material oozes through the holes of the tray, creating a mechanical lock to hold the material in place. When a smooth surface tray is used, there is no mechanical lock, so the interior of the tray is painted or sprayed with an adhesive to hold the impression material securely in the tray.

Adaptation

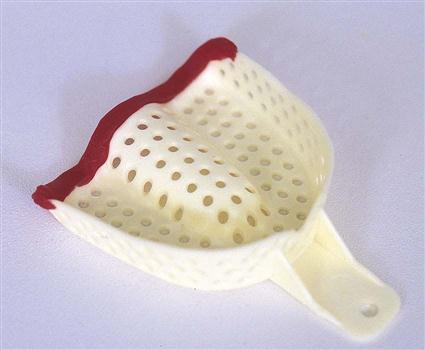

If necessary, the depth or length of the tray can be extended by adding utility wax to the border of the tray. This addition might be necessary if the tray does not completely cover the posterior teeth (Fig. 46-3). For a patient with an unusually high palate, softened utility wax can be added to the palate area of the impression tray.

Custom Trays

A custom tray is constructed to fit the mouth of a specific patient. The dental assistant or the laboratory technician constructs the custom tray in the laboratory from a diagnostic model made from a preliminary impression of the arch before the dentist has prepared the teeth. Chapter 47 describes the construction of a custom tray by using acrylic resin, light-cured resin, or a thermoplastic resin technique.

Tray Adhesives

It is important that an adhesive be dry before the impression material is loaded into the tray. If the adhesive has not had time to dry, the impression will pull away from the tray, causing deformity in the impression. Paint the tray with the adhesive at least 15 minutes before use (Fig. 46-4). Specific adhesives used with specific impression materials are as follows:

• VPS adhesives (blue)—used with polyvinyl siloxane (polysiloxane) and polyether impression materials

• Rubber base adhesives (brown)—used with rubber base impression materials

• Silicone adhesives (orange-pink)—used with silicone impression materials

Hydrocolloid Materials

Hydrocolloid (hydro– meaning water and colloid meaning a gelatinous substance) is a material used to obtain preliminary and final impressions. Depending on the type of hydrocolloid, the physical change from sol (solution) to gel (solid) can be irreversible (changed by chemical factors) or reversible (changed by thermal factors).

Irreversible Hydrocolloid: Alginate

Hydrocolloid impression materials that cannot return to the sol state after they become a gel are termed irreversible hydrocolloids. The change in this physical state results from a chemical change in the material. Cake mix is an example of an irreversible change. When water is added to the powder in a cake mix, a chemical reaction occurs. It is impossible to remove the water and return the mixture to powder.

Alginate is the irreversible hydrocolloid most widely used for preliminary impressions.

Composition and Chemistry

Physical Phases

Hydrocolloid impression materials have two physical phases. First, in the sol (solution) phase, the material is in a liquid or semi-liquid form. Second, in the gel (solid) phase, the material is semisolid, similar to a pudding dessert. The gel strength of hydrocolloid is not as great as that of elastomeric impression materials. The hydrocolloids have difficulty withstanding tensile stress (tearing) and elastic strain (stretching).

Strength

It is important for alginate to be sufficiently strong to resist tearing when the impression is being removed from the patient’s mouth. The strength of the material will continue to increase even after it appears to be set. Because of this process, leaving the impression in the mouth for the full length of time recommended by the manufacturer is important toward achieving maximum strength.

Packaging and Storage

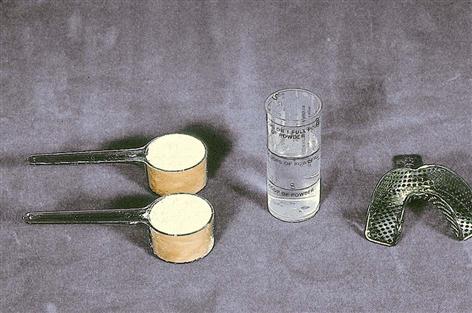

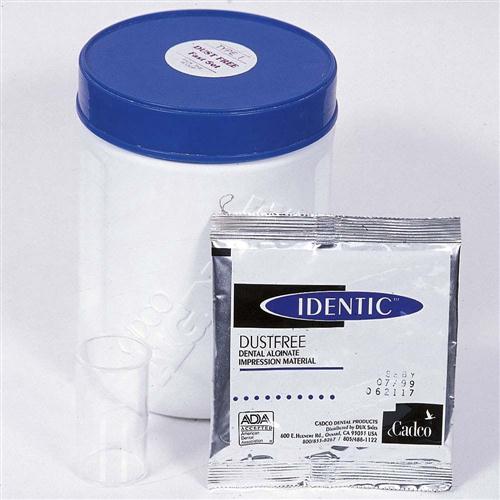

Alginate can be purchased in a variety of ways. Containers about the size of a coffee can are the most common form of packaging. Premeasured, individual packages are more expensive than other types of packaging, but they save time by eliminating the need for measurement of the powder (Fig. 46-5). The material is also supplied with flavoring and changes color when set. Alginate can deteriorate very quickly if exposed to elevated temperatures and moisture, causing the material to not set or to set too rapidly. The shelf life of alginate is approximately 1 year.

Most alginate impression materials must be “poured up” within 1 hour of taking the impression—a requirement dictated by the environment. Because so much of the material is made from water, a slight change in the surroundings can distort the impression and cause dimensional change.

If an alginate impression is stored in water or in a soaked paper towel, the alginate will absorb the additional water and expand. This condition is called imbibition.

If an alginate impression remains in the open air, moisture will evaporate from the material, causing it to shrink and distort. This condition is called syneresis.

Storage of the disinfected impression in a plastic biohazard bag covered with a slightly moistened towel will provide an atmosphere close to 100 percent relative humidity, which causes the least amount of distortion.

Types of Setting

Alginate is available in two settings: normal set and fast set. The types of alginate refer to the working time and the setting time. Normal-set alginate has a working time of 2 minutes and a setting time of up to  minutes after mixing. Fast-set alginate has a working time of

minutes after mixing. Fast-set alginate has a working time of  minutes and a setting time of 1 to 2 minutes.

minutes and a setting time of 1 to 2 minutes.

Working time is the time allowed for mixing the alginate, loading the tray, and positioning the tray in the patient’s mouth.

Setting time is the time required for the chemical action to be completed, after which the impression is ready to be removed from the patient’s mouth.

No difference in the completed impression has been noted between the two setting types of alginates. The decision as to which type to use is based on time-related factors, such as the following:

Altering Setting Time

Room temperature water (21° C/70° F) is best to use when mixing alginate. If additional time is needed for the procedure, then using cooler water will lengthen the setting time. Warmer water will shorten the setting time of the procedure.

Water-to-Powder Ratio

It is important to accurately measure the alginate powder and the water to be mixed. To help ensure accuracy, the manufacturer supplies a plastic scoop for dispensing the bulk powder and a plastic cylinder for measuring the water (Fig. 46-6). The water-to-powder ratio for mixing alginate is clearly marked on these measures. The mixture is equal in ratio: one scoop of powder to one “measure” of water.

Mixing Techniques

The most common mixing technique used for alginate materials is manual spatulation with a rubber bowl and beavertail wide spatula. An additional way that is available is the use of an alginator, which is a rubber flexible bowl attached to an electrical component with a low or high speed (Fig. 46-7). See Procedure 46-1.

Taking an Alginate Impression

It is important for the EFDA to be competent in mixing the alginate, loading the tray, and keeping the patient comfortable while taking the impression.

Explain Procedure to Patient

Before an impression is taken, the procedure must be explained to the patient to ensure his or her comfort. The patient needs to know the following:

Evaluating Alginate Impression

An acceptable alginate impression must meet specific criteria as follows (Fig. 46-8):

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses