9

Die materials

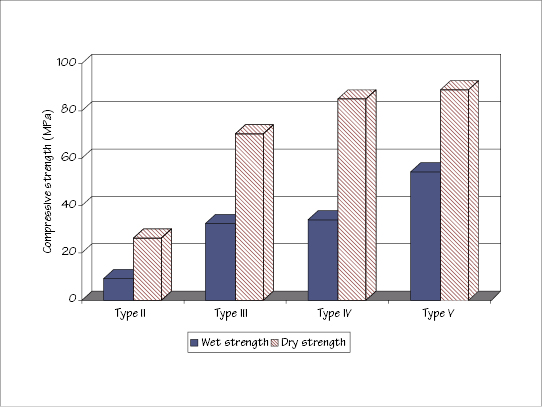

Figure 9.1 Compressive strengths of dental and die stones.

Figure 9.2 A cast prepared for construction of a crown. (Courtesy of Dentsply International.)

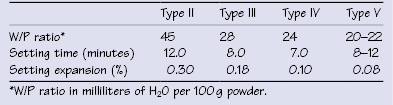

Table 9.1 W/P ratios, setting times, and setting expansions of dental and die stones

9.1 Gypsum products

The most widely used die materials are based on gypsum (Chapter 8), although only Types II, III, and IV are used for models. These hemihydrates are chemically identical but differ in morphology and physical properties.

1 Type II: Model plaster (so-called β-CaSO4·½H2O) has irregularly shaped and porous powder particles and is used to mount models.

2 Type III: Dental stone (so-called α-CaSO4·½H2O) has more uniformly shaped and greater density powder particles than plaster. Type III stone is used to pour study casts that are not being used to fabricate fixed restorations.

3 Type IV: Die stone (high-strength stone, also referred to as α-CaSO4·½H2O) has the highest density powder particles. Die stone is used to fabricate high-strength and abrasion-resistant dies used in fabricating fixed restorations.

4 Type V: The more recently introduced ultrahard, high-expansion die stone, manufactured by autoclaving gypsum, has greater strength than Types III and IV die stones and has optimal expansion for dies and for crown and bridge work. It is particularly suited for pouring polyvinyl and polyether impressions since there is less risk of model fracture during separation from the rigid elastomeric materials. It can also be used as an investing medium for casting gold alloys.

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses