Image processing

Chemical processing

It is CRUCIAL that the stages involved in chemical processing are performed under controlled, standardized conditions with careful attention to detail. Strict quality assurance procedures must be applied (see Ch. 17). Unfortunately, all too often in dental practice poor chemical processing is the cause of radiographic films being of inadequate diagnostic quality, irrespective of how reliable and expensive the X-ray equipment or how accurate the operator’s radiographic techniques.

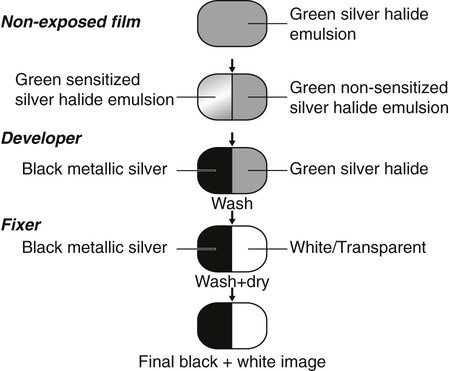

Theory

A detailed knowledge of the chemistry involved in processing is not essential. However, a working knowledge and understanding of the theory of processing is necessary so that processing faults can be identified and corrected. A simplified approach to the stages involved in converting the green film emulsion into the black/white/grey radiograph is shown in Fig. 5.1 and outlined below:

Practical methods

There are three practical chemical processing methods available:

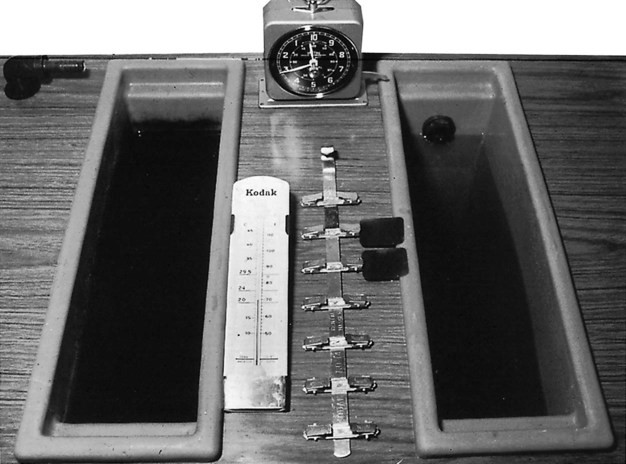

Manual processing

• Adequate film storage facilities

• Safelights – positioned 1.2 m from the work surfaces with 25 W bulbs and filters suitable for the type of film being used (see Ch. 17)

Manual processing cycle

1. The exposed film packet is unwrapped and the film clipped on to a hanger.

2. The film is immersed in developer and agitated several times in the solution to remove air bubbles and left for about five minutes at 20 °C.

3. The residual developer is rinsed off in water for about 10 seconds.

4. The film is immersed in fixer for about 8–10 minutes.

5. The film is washed in running water for about 10–20 minutes to remove any residual fixer.

Processing solutions

Two different processing solutions are required, the developer and the fixer. The typical constituents of these solutions are shown in Tables 5.1 and 5.2.

Table 5.1

The typical constituents of developer solution and their functions

| Constituents | Functions |

| Phenidone | Helps bring out the image |

| Hydroquinone | Builds contrast |

| Sodium sulphite | Preservative – reduces oxidation |

| Potassium carbonate | Activator – governs the activity of the developing agents |

| Benzotriazole | Restrainer – prevents fog and controls the activity of the developing agents |

| Glutaraldehyde | Hardens the emulsion |

| Fungicide | Prevents fungal growth |

| Buffer | Maintains pH (7+) |

| Water | Solvent |

Table 5.2

The typical constituents of fixer solution and their functions

| Constituents | Functions |

| Ammonium thiosulphate | Removes unsensitized silver halide crystals |

| Sodium sulphite | Preservative – prevents deterioration of the fixing agent |

| Aluminium chloride | Hardener |

| Acetic acid | Acidifier – maintains pH |

| Water | Solvent |

Important points to note regarding development

• The alkaline developer solution should be made up to the concentration recommended in the manufacturer’s instructions.

• The developer solution is oxidized by air and its effectiveness decreased. Solutions should be used for no more than 10–14 days, irrespective of the number of films processed during that time.

• If the development process is allowed to continue for too long, more silver will be deposited than was intended and the radiograph will be too dark. Conversely, if there is too short a development time the radiograph will be too light.

• Development time (in fresh solutions) is dependent on the temperature of the solution. The usual value recommended is five minutes at 20°C.

• If the temperature is too high, development is rapid, the film may be too dark and the emulsion may be damaged. If the temperature is too low, development is slowed and a pale film will result.

Stay updated, free dental videos. Join our Telegram channel

VIDEdental - Online dental courses